Molecule printing materials for selectively reducing cigarette fume TSNA amount and application thereof

A technology of cigarette smoke and molecular imprinting, applied in application, tobacco, e-liquid filter and other directions, can solve problems such as energy consumption and environmental pollution, and achieve the effects of reducing harm, strong operability, and small addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of Additives

[0033] 1.1 Weigh 0.327g (0.003mmol) 3-pyridinemethanol, dissolve 1.032g (0.012mmol) methacrylic acid in 30ml chloroform, ultrasonically disperse for 10min, then add 11.88g (0.06mmol) ethylene glycol dimethacrylate and 120mg of azoisobutyronitrile, mixed well, and nitrogen gas was introduced for 5 minutes, and the reaction vessel was sealed under vacuum. The reaction vessel was placed in a constant temperature water bath at 65°C for 24 hours for polymerization. The product is ground and sieved to obtain 40-60 mesh particles.

[0034] 1.2 Place the particles in a Soxhlet extractor, extract them repeatedly with methanol solution containing acetic acid for 24 hours, then remove residual acetic acid and methanol with chloroform, wash with distilled water, and dry in vacuum before use.

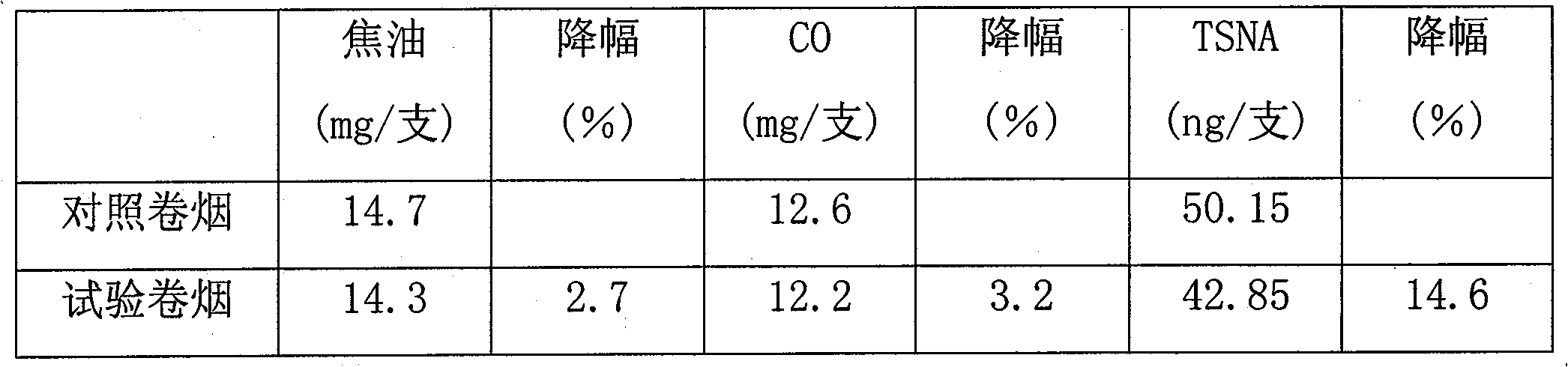

[0035] 2. Add the prepared polymer to the mouthpiece at 40 mg / cigarette, and use the SM400 smoking machine to perform smoke detection according to the standard...

Embodiment 2

[0039] 1. Preparation of Additives

[0040] 1.1 Weigh 0.366g of nicotinamide, 1.032g of methacrylic acid dissolved in 30ml of chloroform, ultrasonically disperse for 10min, then add 11.88g of ethylene glycol bismethacrylate and 120mg of azoisobutyronitrile, mix well and pass nitrogen gas for 5min , and seal the reaction vessel under vacuum. The reaction vessel was placed in a constant temperature water bath at 65°C for 24 hours for polymerization. The product is ground and sieved to obtain 40-60 mesh particles.

[0041] 1.2 Place the particles in a Soxhlet extractor, extract them repeatedly with methanol solution containing acetic acid for 24 hours, then remove residual acetic acid and methanol with chloroform, wash with distilled water, and dry in vacuum before use.

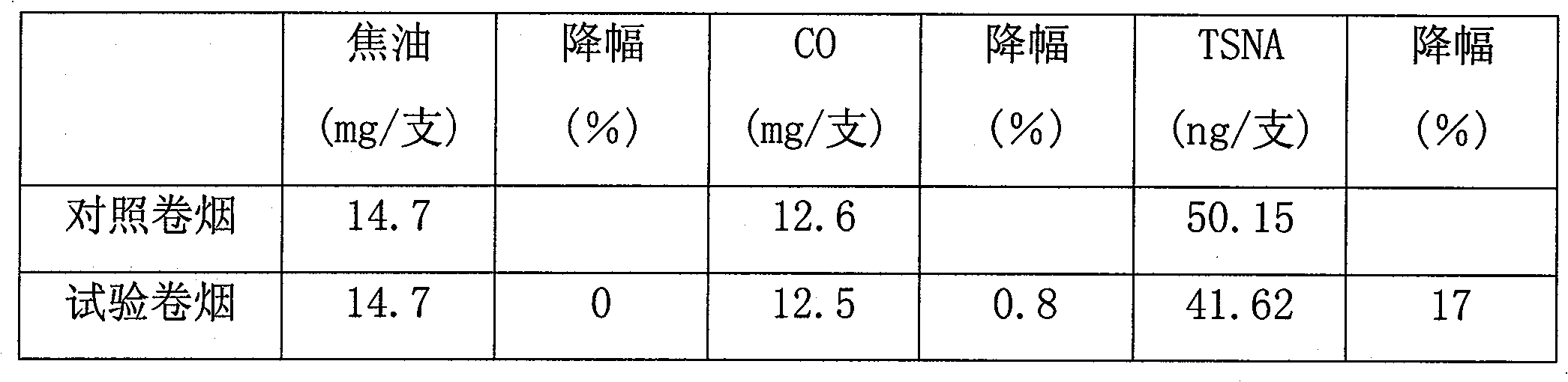

[0042] 2. Add the prepared polymer to the mouthpiece at 40 mg / cigarette, and use the SM400 smoking machine to perform smoke detection according to the standard smoke detection method. The smoke detection resul...

Embodiment 3

[0046] 1. Preparation of Additives

[0047] 1.1 Weigh 0.363g of 3-acetylpyridine, 1.032g of methacrylic acid dissolved in 30ml of chloroform, ultrasonically disperse for 10min, then add 11.88g of ethylene glycol bismethacrylate and 120mg of azoisobutyronitrile, mix well and then pass into Nitrogen for 5 min, and the reaction vessel was sealed under vacuum. The reaction vessel was placed in a constant temperature water bath at 65°C for 24 hours for polymerization. The product is ground and sieved to obtain 40-60 mesh particles.

[0048] 1.2 Place the particles in a Soxhlet extractor, extract them repeatedly with methanol solution containing acetic acid for 24 hours, then remove residual acetic acid and methanol with chloroform, wash with distilled water, and dry in vacuum before use.

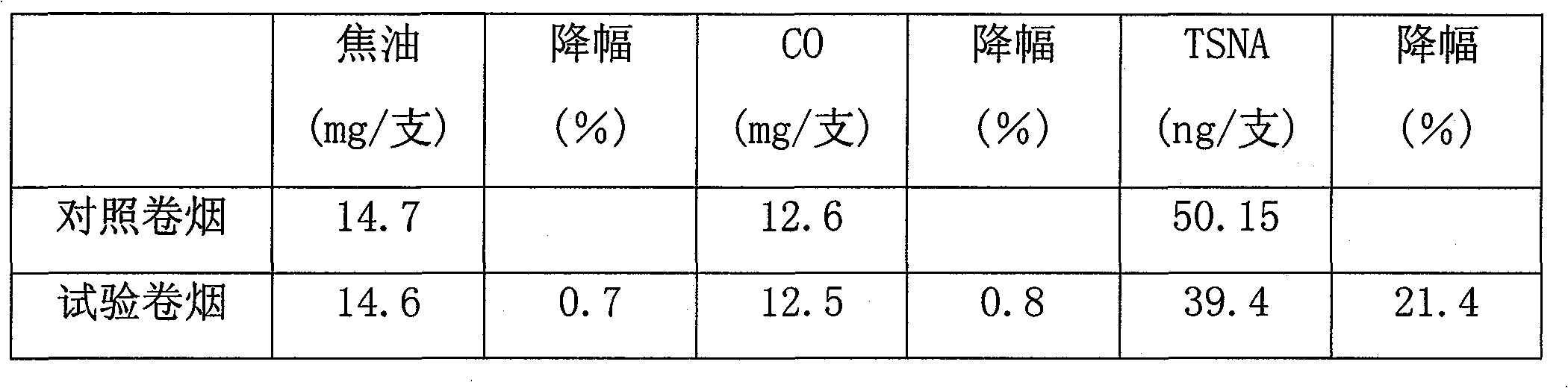

[0049] 2. Add the prepared polymer to the mouthpiece at 40 mg / cigarette, and use the SM400 smoking machine to perform smoke detection according to the standard smoke detection method. The smoke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com