A method for separating and removing tsna in burley tobacco extract by electrodialysis

An electrodialysis method and electrodialysis technology, applied in the field of separation, can solve the problems of limited treatment effect of extracts, reduction of TSNA content, limited adsorption capacity, etc., to avoid the increase of TSNA release in flue gas, simple process flow, acid use less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

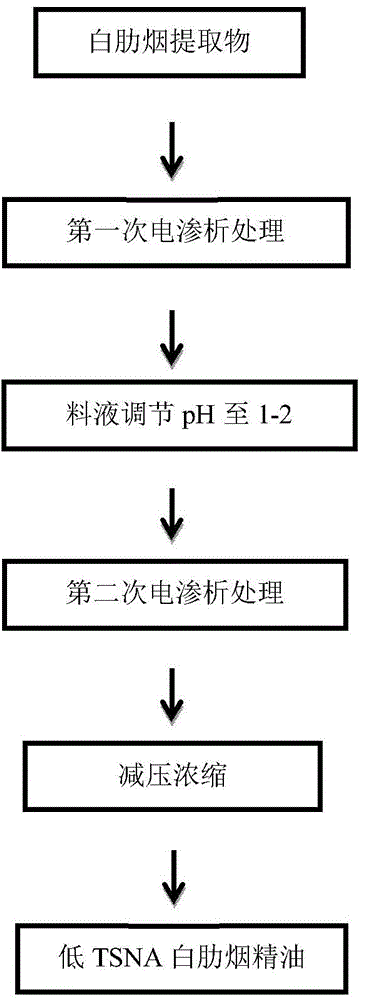

Image

Examples

Embodiment 1

[0024] In the present embodiment, the specific process of the method for separating and removing TSNA in the Burley tobacco extract by electrodialysis is as follows:

[0025] 1) The first electrodialysis desalination treatment

[0026] Burley tobacco extract with a soluble content of 10% at 15A / cm 2 Electrodialysis desalination treatment under constant current density conditions until the membrane stack voltage drops to a stable value of 60V, and then electrodialysis desalination treatment under 60V steady voltage conditions until the conductivity is 1ms / cm;

[0027] The burley tobacco extract is obtained by solid-liquid extraction with burley tobacco as raw material and 70-95vt% (volume percentage concentration, the same below) ethanol solution as the extraction agent. The extraction temperature is 50°C and the extraction time is 1h.

[0028] 2) The second electrodialysis desalination treatment

[0029] The pH value of the mixed solution obtained after the first electrodia...

Embodiment 2

[0032] In the present embodiment, the specific process of the method for separating and removing TSNA in the Burley tobacco extract by electrodialysis is as follows:

[0033] 1) The first electrodialysis desalination treatment

[0034] Burley tobacco extract with a soluble content of 8% at 20A / cm 2 Electrodialysis desalination treatment under constant current density conditions until the membrane stack voltage drops to a stable value of 60V, and then electrodialysis desalination treatment under 60V steady voltage conditions until the conductivity is 1ms / cm;

[0035] The burley tobacco extract is obtained by solid-liquid extraction with burley tobacco as a raw material and 70-95vt% ethanol solution as an extraction agent. The extraction temperature is 50° C. and the extraction time is 1 h.

[0036] 2) The second electrodialysis desalination treatment

[0037] The pH value of the mixed solution obtained after the first electrodialysis desalination treatment was adjusted to 1.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com