Hard coating film

A hard coating film and hard coating technology, applied in the direction of coatings, devices for coating liquid on the surface, instruments, etc., can solve problems such as insufficient hardness, and achieve the effect of small curling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

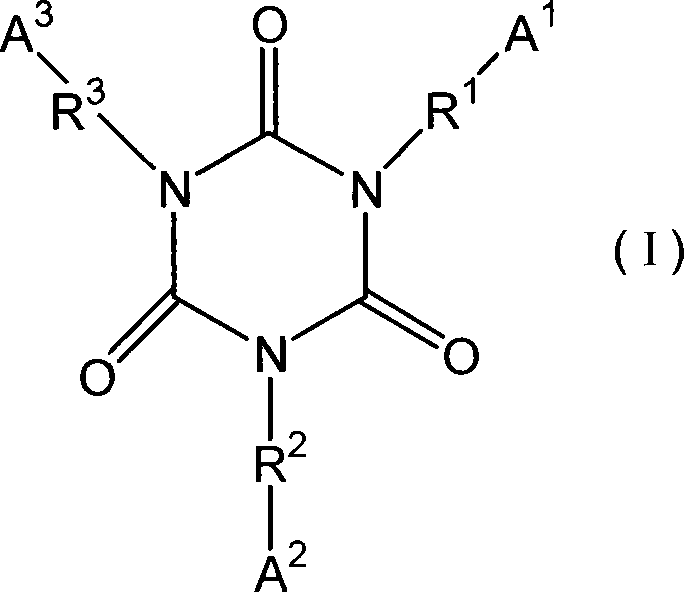

Method used

Image

Examples

Embodiment 1

[0080] Using a bar coater, the coating liquids A to G prepared in Preparation Examples 1 to 7 were coated on a 40 μm thick triacetyl cellulose film (manufactured by Fuji Photo Film Co., Ltd., trade name "T40UZ") as a base film , And make the thickness after drying 3μm. After drying at 70℃ for 1 minute, irradiate ultraviolet rays to the coated surface, and the amount of irradiation light is 230mJ / cm 2 , Curing, manufacturing hard coating film. The thickness of the hard coat layer is 3 μm.

[0081] Table 1 shows the performance evaluation results of each hard coat film.

Embodiment 2

[0083] Except that in Example 1, coating was performed so that the thickness after drying was 6 μm, various hard coating films were produced in the same manner as in Example 1. The thickness of the hard coat layer is 6 μm.

[0084] Table 1 shows the performance evaluation results of each hard coat film.

Embodiment 3

[0086] Except that in Example 1, coating was performed so that the thickness after drying was 10 μm, various hard coating films were produced in the same manner as in Example 1. The thickness of the hard coat layer is 10 μm.

[0087] Table 1 shows the performance evaluation results of each hard coat film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com