Method and device for quickly preparing natural gas hydrate by employing static hypergravity

A technology of natural gas and hydrate, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., which can solve the problems of difficult to realize industrial production, unable to effectively solve the problems of rapid update, rapid removal of hydration reaction heat, and unsatisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

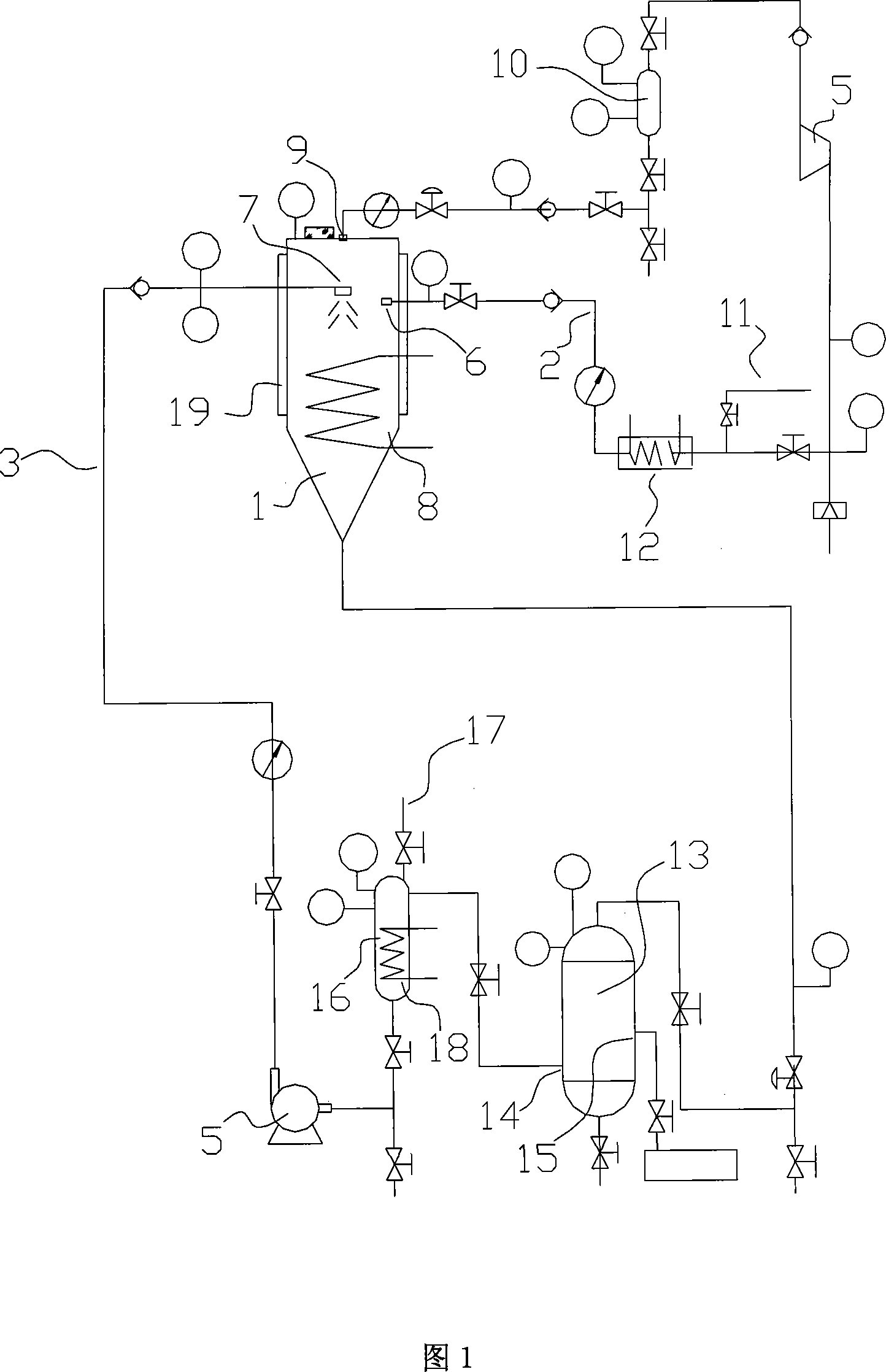

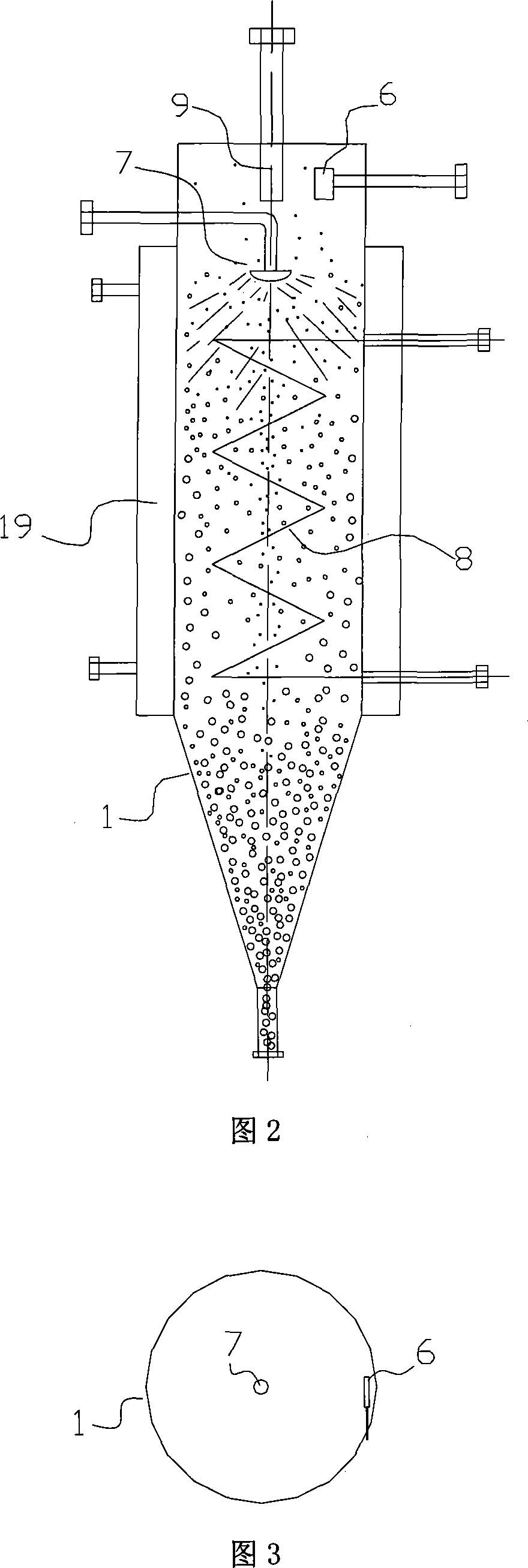

[0028] As shown in Fig. 1 and Fig. 2, a device for rapidly preparing natural gas hydrate by static supergravity is connected with an inlet pipeline 2, a water inlet pipeline 3 and a discharge pipeline 4 on a cylindrical reactor 1; Both the gas pipeline 2 and the water inlet pipeline 3 are provided with a compression device 5; the inlet pipeline 2 is provided with a nozzle 6, and the water inlet pipeline 3 is provided with a nozzle 7; the nozzle 6 and the nozzle 7 are all placed in the reactor 1, and the nozzle 6 is arranged on the inner wall of the reactor 1 and faces the circumferential direction of the reactor, and the nozzle 7 is arranged on the upper axis position of the reactor 1; Heat exchange coils are adopted), and an exhaust port 9 is provided above the reactor 1.

[0029] Wherein, a buffer tank 10 is provided on the intake pipeline 3, and the exhaust port 9 communicates with the buffer tank 10, and a compression device 5 (ie, a compressor), a cooler 12 and an air inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com