Liquid-phase epitaxy graphite boat preventing boat-sticking of mother liquid

A technology of liquid phase epitaxy and graphite boats, which is applied in the field of graphite boats for liquid phase epitaxy equipment, can solve the problems of prolonging the growth cycle, increasing the difficulty of growth, and failing to grow graphite boats, and achieving the effect of broadening the application range and preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the specific embodiment of the present invention is described in further detail:

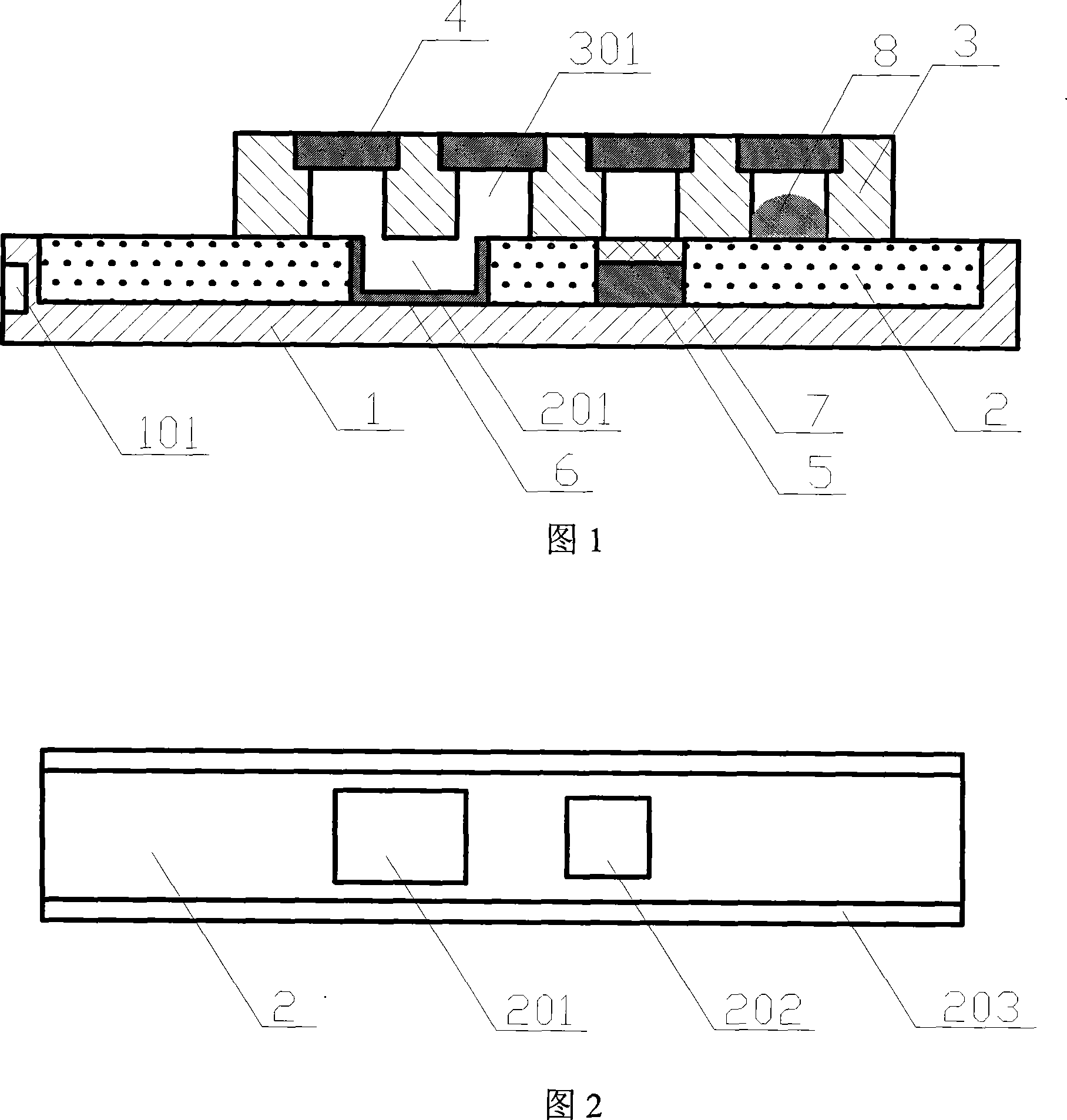

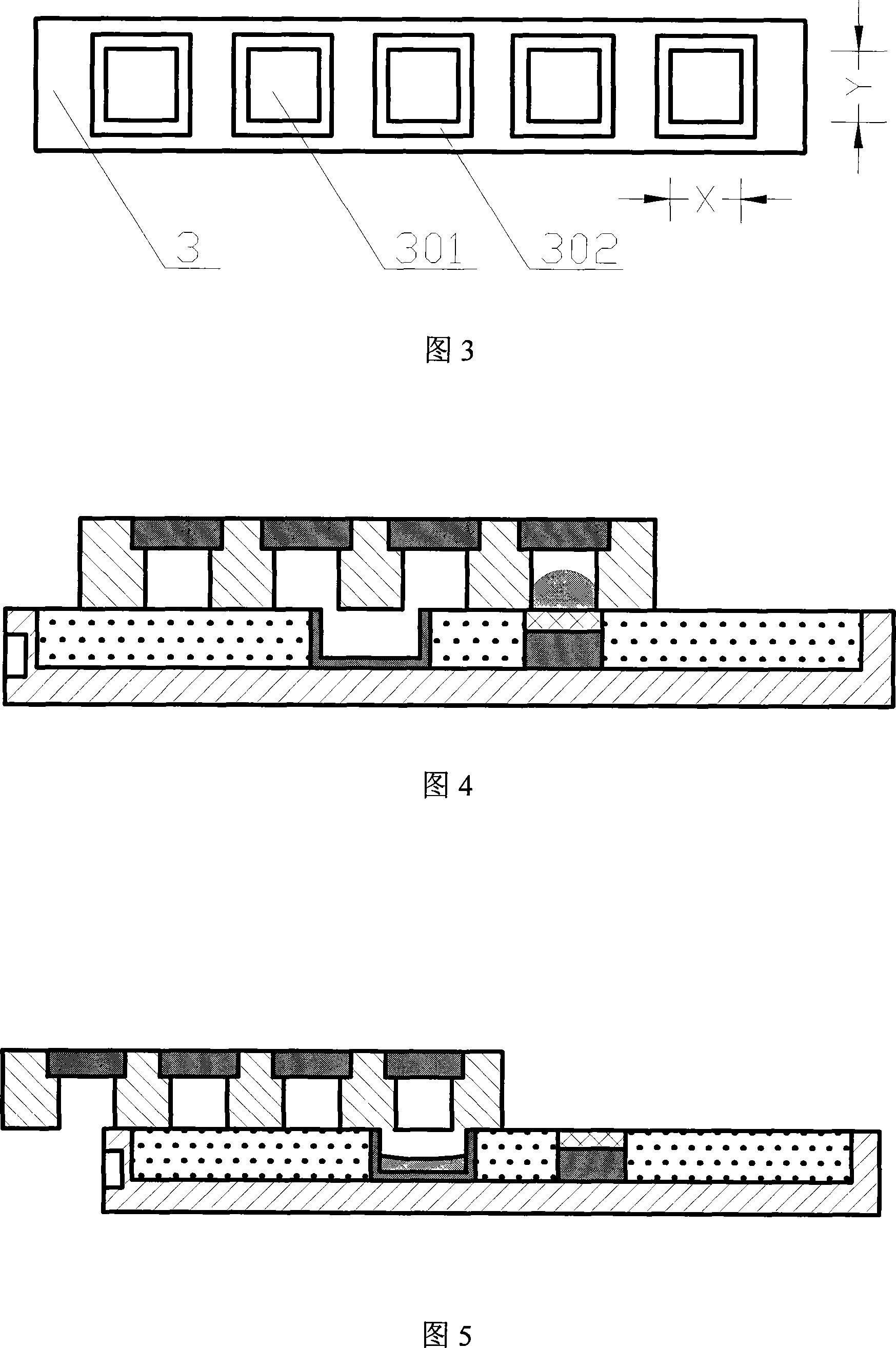

[0016] As shown in Figure 1, the embodiment of the present invention adopts a stacked structure, and the graphite boat is divided into upper, middle and lower layers. The lower layer is the base 1, which has a groove in the middle of which is consistent with the shape and size of the base plate 2, and is used to inlay and install the base plate 2. There is a rectangular hole 101 on the left side of the base plate 2 to fix the graphite boat; the middle layer is inlaid on the base 1 The bottom plate 2 in the groove in the middle has a structure as shown in Figure 2, and two cavities are arranged in the middle of the bottom plate 2, namely, the cavity 201 for placing the recovery boat 6 and the space for placing the graphite gasket 5 and the substrate 6. The cavity 202 is equipped with guide rails 203 on both sides of the upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com