Method for measuring boilling point distribution of coal and rock oil deriving heavy oil products with liquid phase chromatography

A liquid chromatography and high performance liquid chromatography technology, applied in the field of determination of the boiling point distribution of heavy oil products, can solve the problems of limited maximum distillation temperature, inability to distill heavy substances, long distillation time of equipment, etc., and achieve sample processing The effect of small amount, low toxicity and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

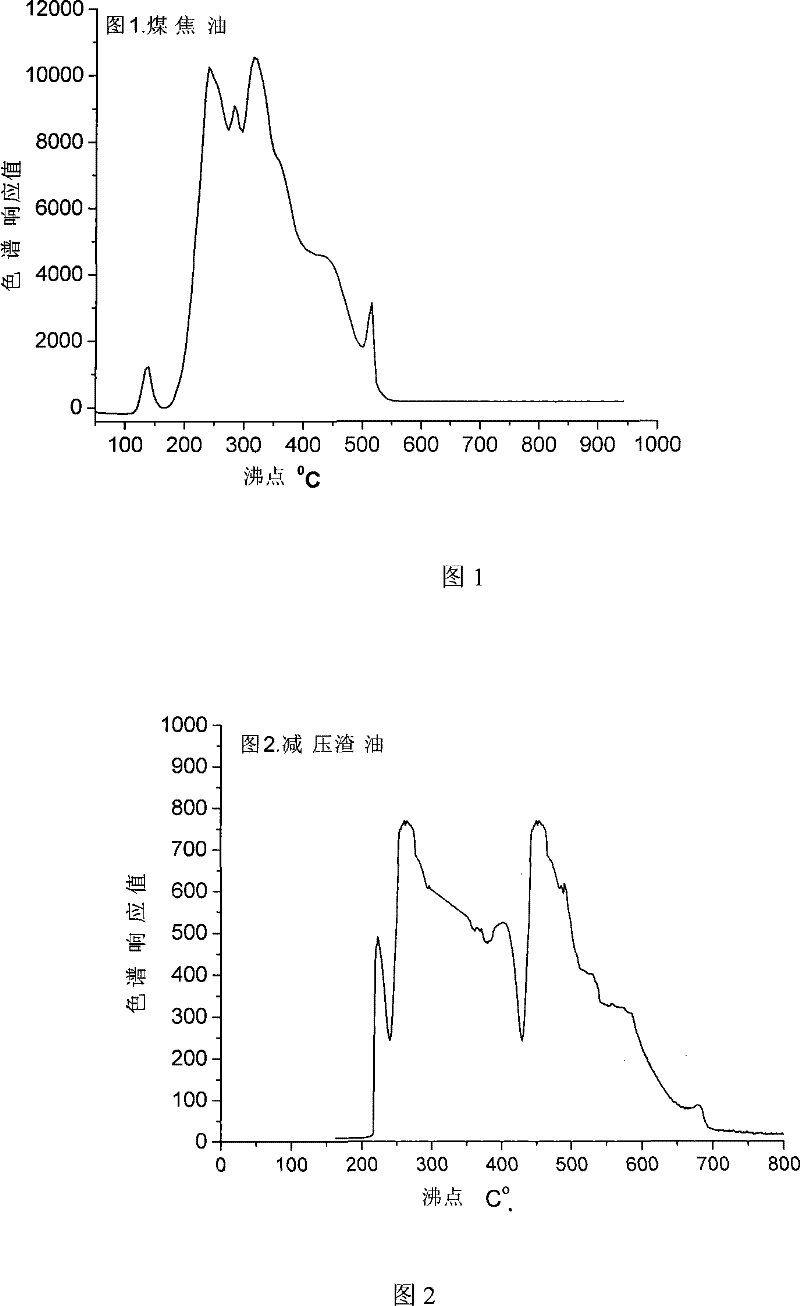

[0038] ①Sample name: a kind of coal tar.

[0039] ②Analysis process:

[0040] Sample preparation: prepare a 0.1 g / 100 ml tetrahydrofuran analysis sample.

[0041] Chromatographic analysis: the model of the chromatographic column used is SHIMPACK GPC-801, the length of the chromatographic column is 30 cm, the inner diameter is 0.8 cm, the flow of tetrahydrofuran is the mobile phase, the flow rate is 1.2 ml / min, the temperature of the chromatographic column: 25 ° C, under this condition , the sample was injected into the column with 2 microliters, and the chromatographic peak of the sample was recorded until the end.

[0042] Processing of chromatograms: After the chromatographic analysis is completed, obtain the time and chromatographic peak response value, and replace the time (Z coordinate) with the boiling point °C value through Y=940.91268-97.10393×Z, that is, the boiling point °C-peak response diagram of the sample is obtained. The chromatogram is divided into different ...

Embodiment 2

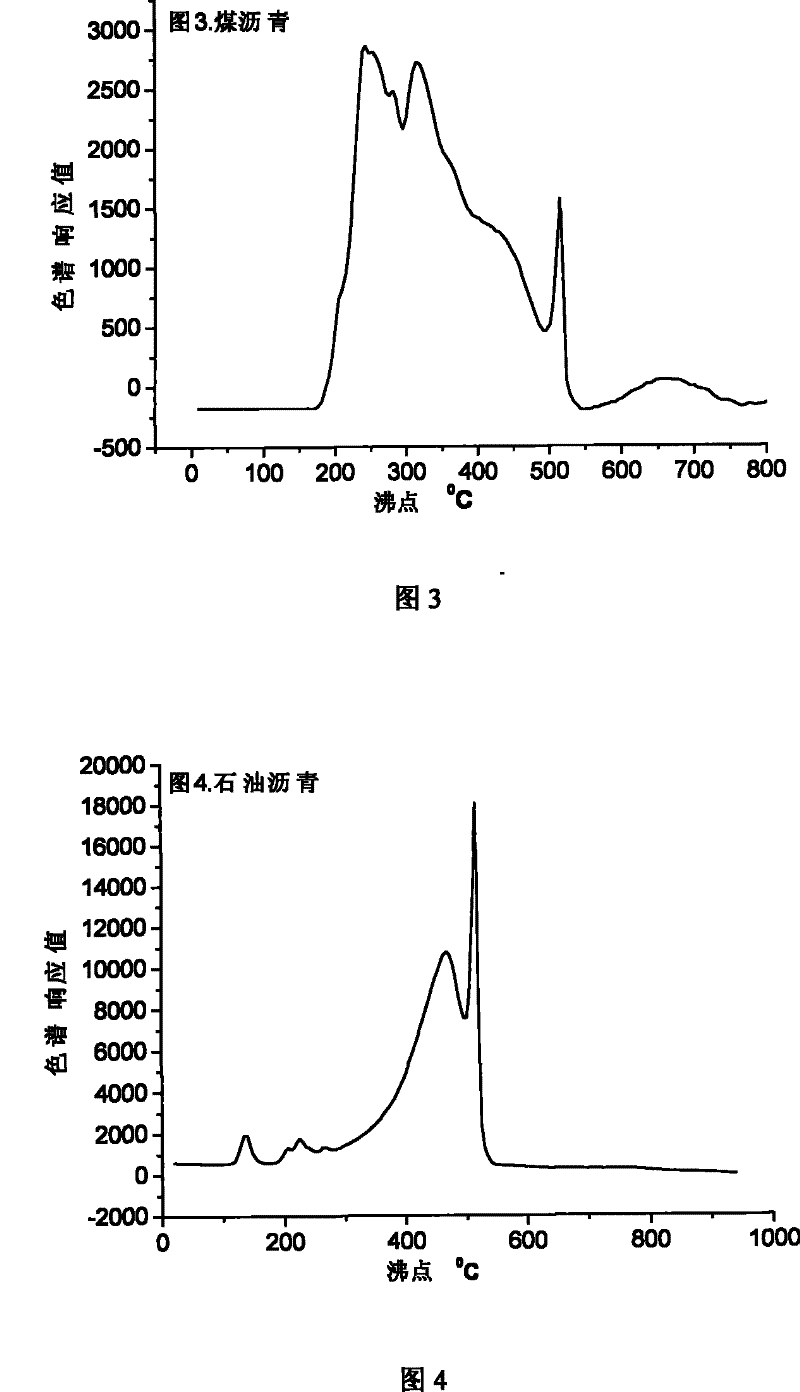

[0046] ①Sample name: a petroleum vacuum residue

[0047] ② analysis process: same as embodiment 1.

[0048] ③Analysis results: The boiling point distribution results of the samples are listed in Table 3, and the chromatogram is shown in Figure 2.

[0049] A kind of petroleum vacuum residue boiling point distribution (W%) measurement result of table 3

[0050] Boiling point °C

Embodiment 3

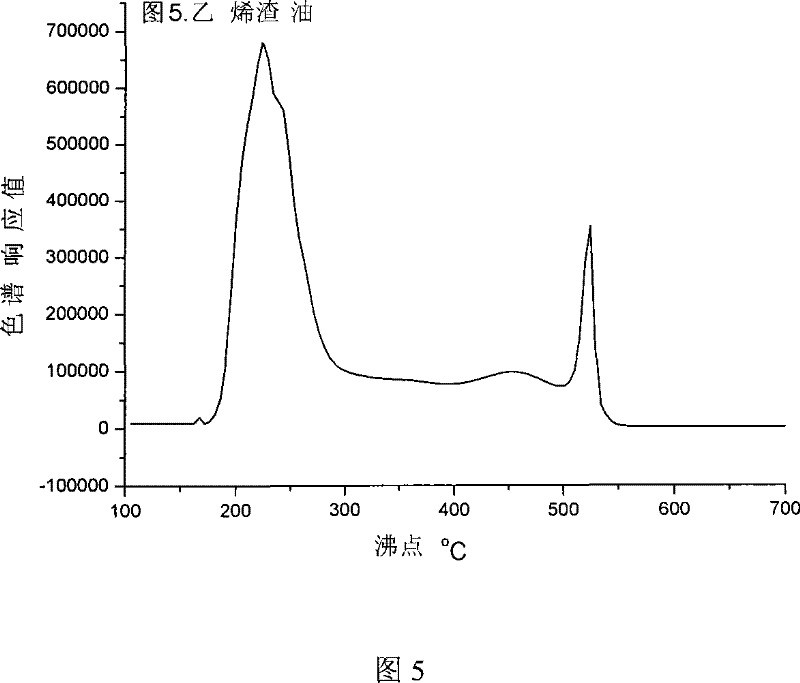

[0052] ①Sample name and type: a kind of coal tar pitch

[0053] ②Analysis process: Divide the chromatogram into different specific areas, that is, the areas with boiling points 600, and then pass the chromatographic peak area corresponding to the boiling point range. The percentage of the total chromatographic peak area of the range can be used to obtain the content of different boiling point ranges. All the other are the same as in Example 1.

[0054] ③Analysis results: The results of the boiling point distribution of the samples are listed in Table 4, and the chromatogram is shown in Figure 3. It can be seen from Table 4 that the quantitative deviation is very small.

[0055] The boiling point distribution (W%) measurement result of a kind of coal tar pitch of table 4

[0056] Boiling point °C

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com