Thrust disc of release bearing of a disconnect clutch

A technology for release bearings and thrust plates, applied in clutches, mechanical drive clutches, mechanical equipment, etc., can solve problems such as low structural strength, short service life, and large wear, and achieve slipping suppression, easy operation, and self-determined acceleration heart effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

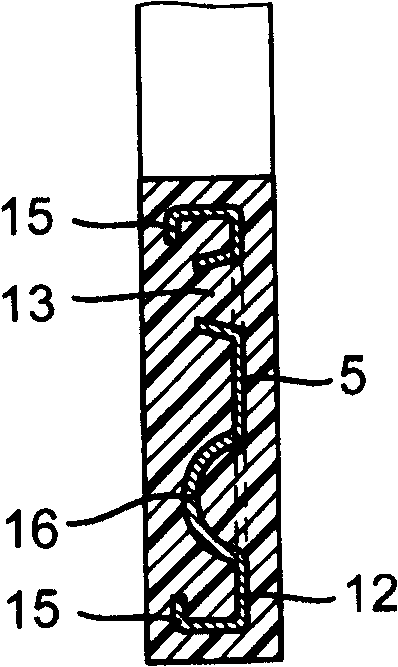

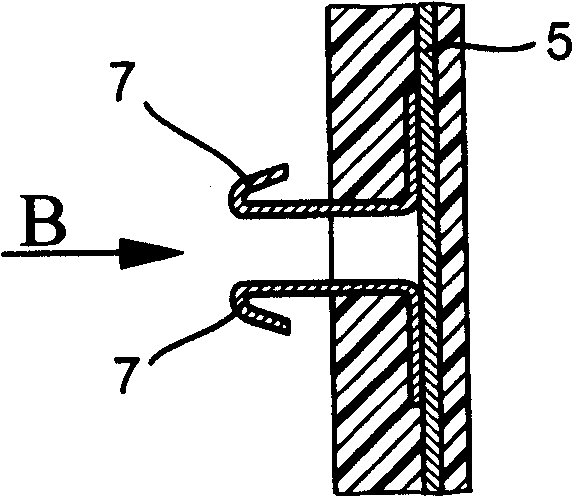

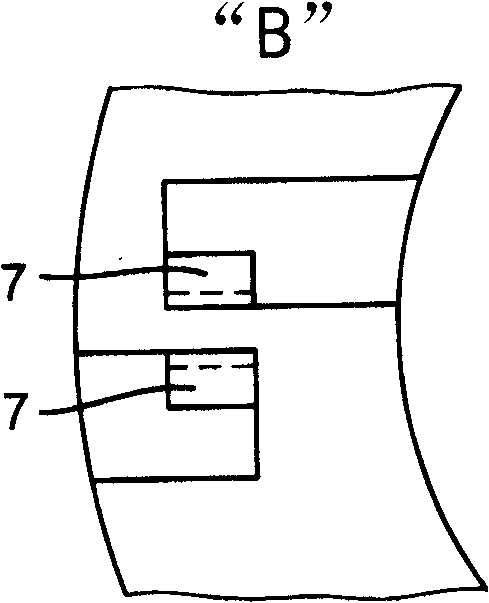

[0037] figure 1 Represent the longitudinal sectional view of thrust plate 1 of the present invention, corresponding to figure 2 A-A line in.

[0038] figure 2 means along figure 1 The view of the thrust plate 1 in the direction of the arrow "X", while Figure 1a is figure 1 Detail drawing of detail "Z".

[0039] The effect of the thrust plate 1 is to transmit the release force of the release bearing to the reed 2 of the disk spring of a shift release clutch. Neither the shift release clutch and the release bearing with disk springs are shown.

[0040]During disengagement and engagement, slippage occurs between the leaf reed 2 and a clutch-facing face 3 of the thrust disk 1 . Thus, the thrust plate wears on the contact surface of the reed 2. The contact surface is designed as a concavely curved circumferential groove 4 into which the end of the tongue 2 engages with a coaxial curvature.

[0041] Below the circumferential groove 4, there is a reinforcing rib 5, see al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com