Ultra-sophisticated aerostatic motorized spindle system

A gas static pressure, electric spindle technology, which is applied to bearings, electromechanical devices, electrical components, etc., can solve the problems of inability to achieve direct drive, poor power transmission between the motor and the spindle, and poor rotation accuracy, and achieve simple structure and rotation. High degree and good dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

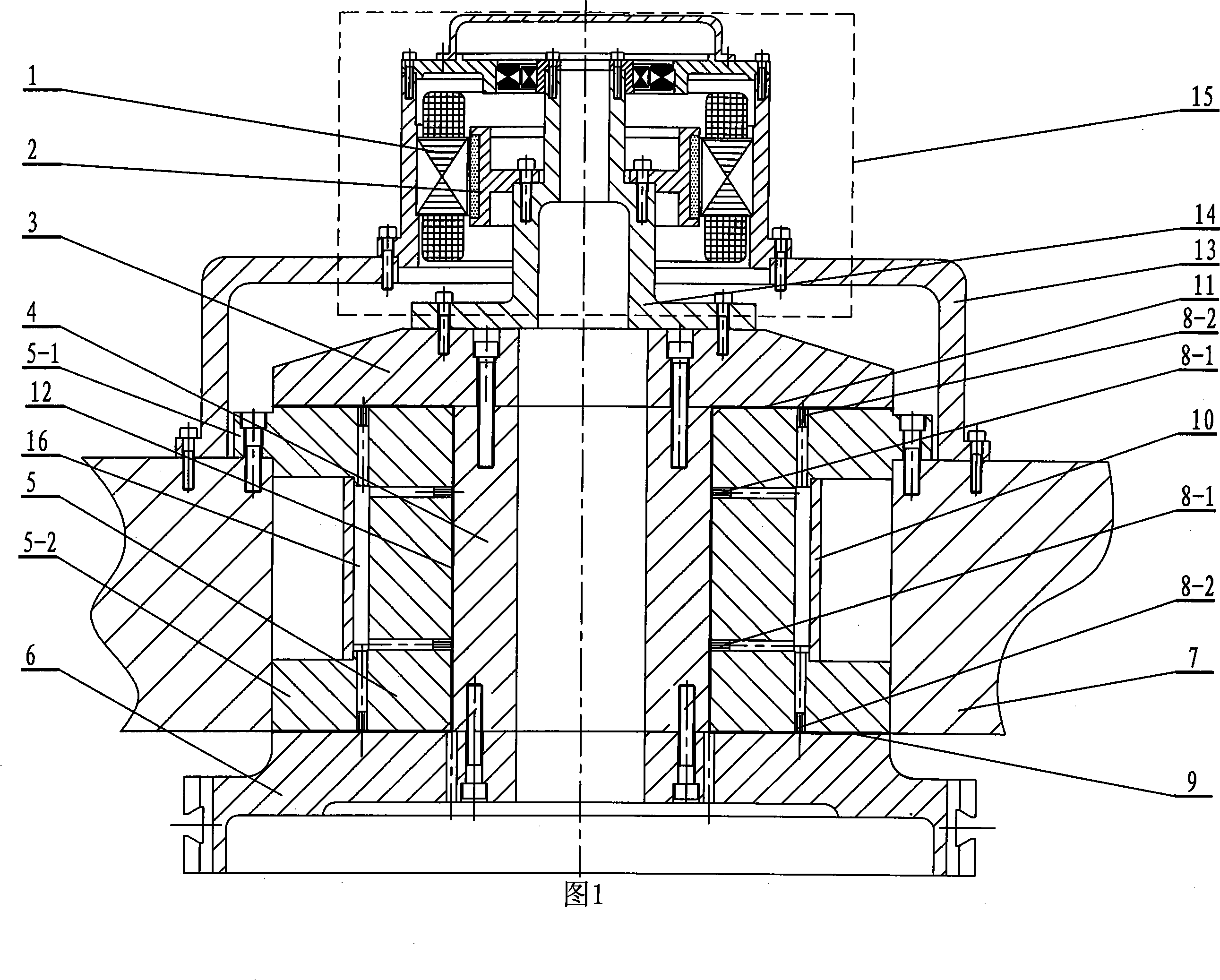

[0007] Specific embodiment 1: As shown in Figure 1, the ultra-precision gas static piezoelectric spindle system of this embodiment is composed of a DC brushless drive motor 15, a spindle 4, an upper thrust plate 3, a lower thrust plate 6, and a shaft sleeve 5. , The DC brushless drive motor 15 is located above the upper thrust plate 3, the motor shaft 14 on the DC brushless drive motor 15 is fixedly connected to the upper end surface of the upper thrust plate 3, and the main shaft 4 and the sleeve 5 are both located on the upper Between the thrust plate 3 and the lower thrust plate 6, the bushing 5 is sleeved on the main shaft 4. The lower end surface of the upper thrust plate 3 is fixedly connected with the upper end surface of the main shaft 4, and the lower end surface of the main shaft 4 is connected to the lower thrust plate 6 The upper end surface is fixedly connected, the motor shaft 14 is coaxial with the main shaft 4, and the sleeve 5 is provided with a plurality of radia...

specific Embodiment approach 2

[0009] Specific embodiment 2: As shown in Fig. 1, the upper end of the sleeve 5 of this embodiment is provided with an upper end boss 5-1, the lower end of the sleeve 5 is provided with a lower end boss 5-2, and the upper end boss 5-1 It is fixedly connected to the shafting bracket 7, and the lower end boss 5-2 is in contact with the inner wall of the shafting bracket 7. This design is easy to install. The other composition and connection relationship are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific embodiment 3: As shown in FIG. 1, this embodiment further includes an air chamber sleeve 10, and the air chamber sleeve 10 is sleeved on the shaft sleeve 5. In this design, a closed air chamber 16 is formed between the air chamber sleeve 10 and the shaft sleeve 5 to improve the effect of the gas static pressure and the rotation accuracy of the main shaft. The other composition and connection relationship are the same as in the first embodiment.

[0011] working principle:

[0012] The stator 1 and the rotor 2 constitute a DC brushless drive motor 15. Since there is no brush, there is no frictional torque between the stator 1 and the rotor 2 of this motor, and a rotating torque can be directly generated to drive the spindle 4 to rotate and perform cutting. The upper thrust plate 3 and the lower thrust plate 6 of the aerostatic bearing are connected to the main shaft 4, and the length of the main shaft 4 and the height of the sleeve 5 are ground during manufacture to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com