Hose co-moldable with plastic tub, in particular for a washing machine

A technology for washing machines and plastic buckets, which is applied in the hose field of washing machines, and can solve problems such as the withdrawal of the bearing itself, loosening of the connection, and movement of the bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

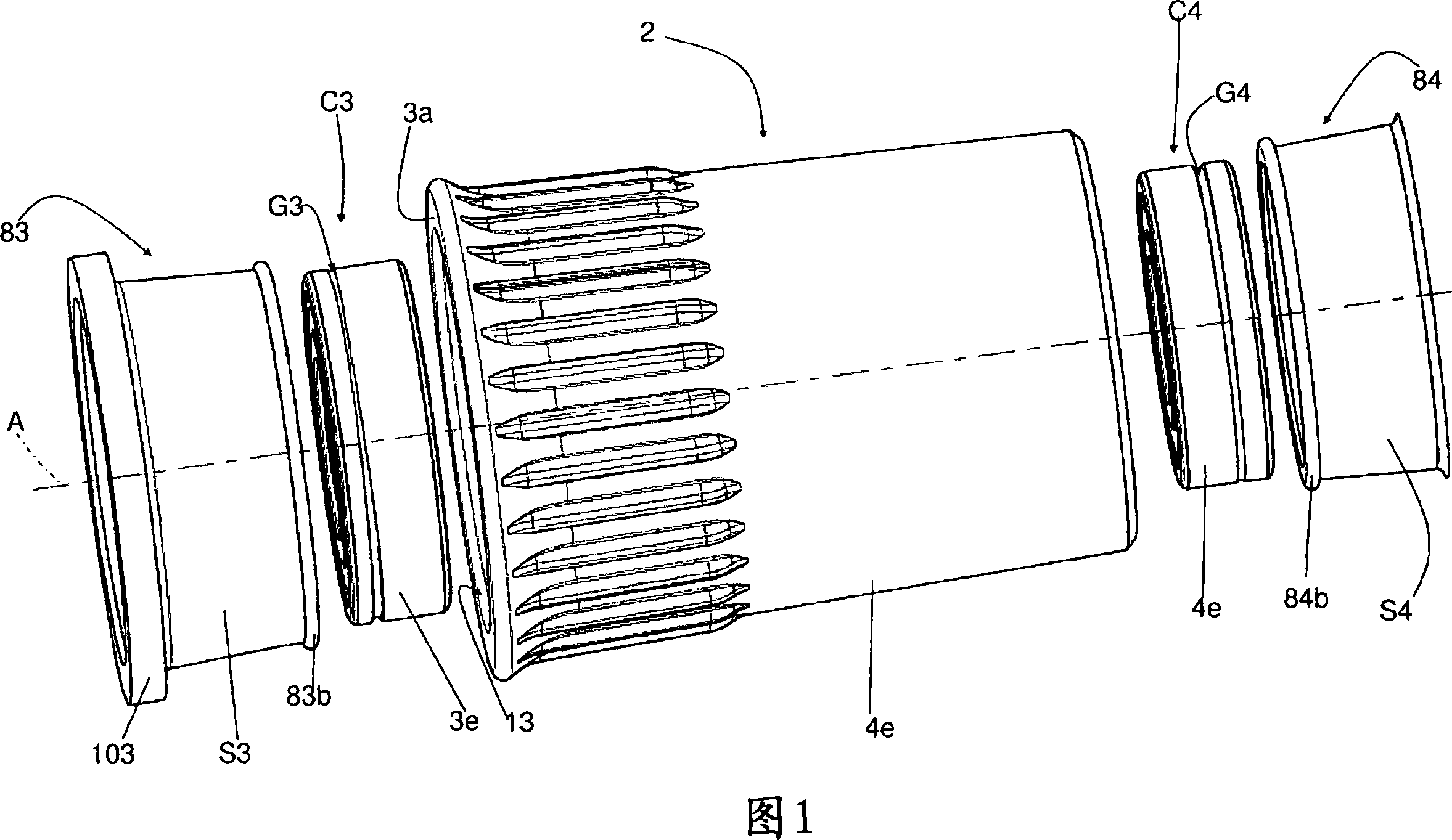

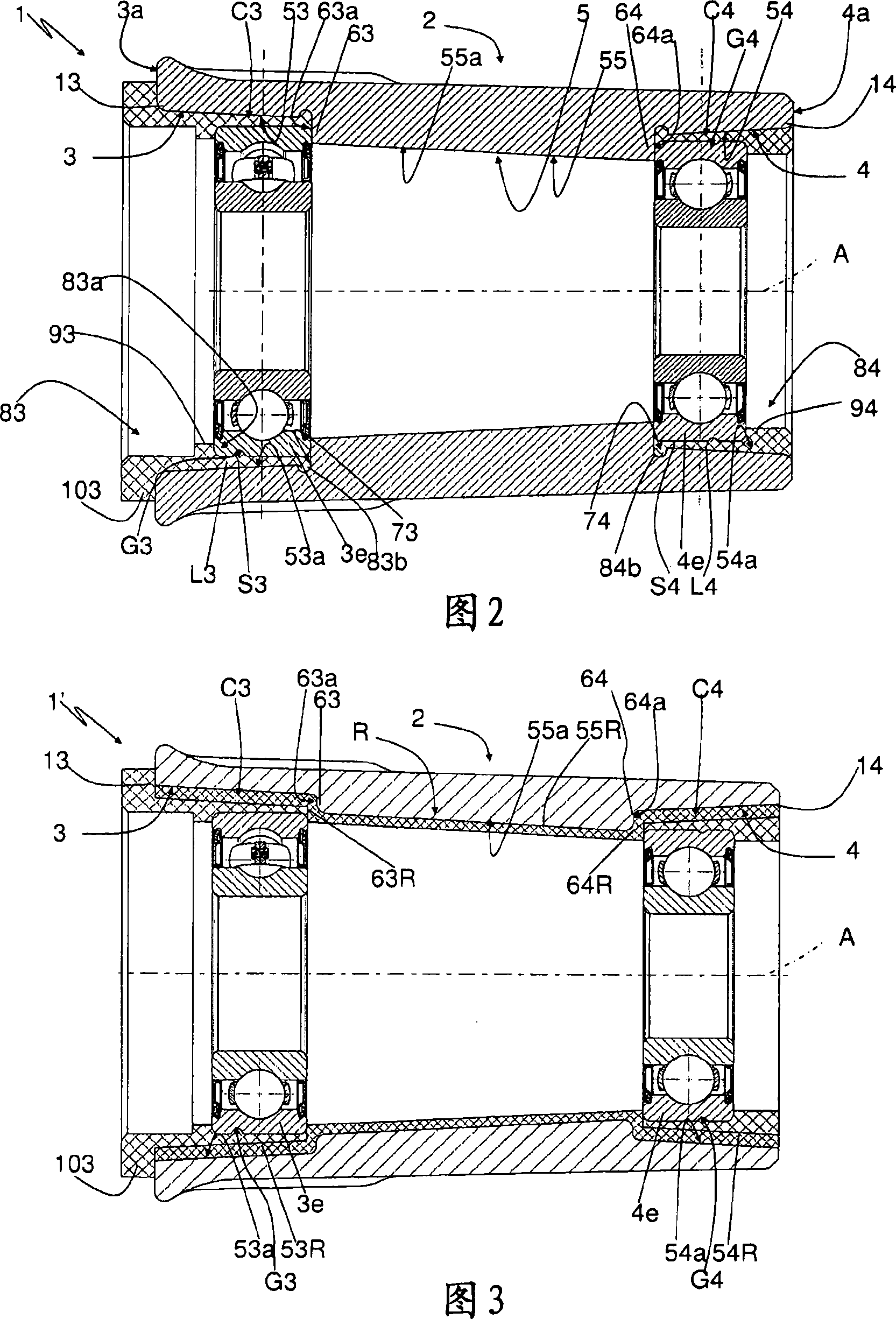

[0010] Referring to Figures 1 and 2, numeral 1 designates a hose which may be integrally co-moulded with the washing machine tub.

[0011] A hose 1 has a longitudinal axis A and comprises a hollow metallic tubular body 2 extending along axis A, two casings 3 and 4 corresponding to opposite ends of the tubular body 2, and two Internal rolling bearings C3 and C4, which are better described in the description below.

[0012] The tubular body 2 is axially delimited by two annular end faces 3a and 4a, which delimit the inlet boundaries 13 and 14 for the housings 3 and 4, respectively, and which are internally composed of an inner section 55 and two inlets The conduit 5 of the sections 53 and 54 passes through, the inlet sections 53 , 54 extending from the borders 13 and 14 respectively towards the section 55 and delimiting the housings 3 and 4 .

[0013] In particular, the inner section 55 has a diameter smaller than that of each of the sections 53 and 54 and defines together with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com