Method for detecting iron member using magnetosensitive element by constant magnetic deironing device

A magnetic sensitive element and iron remover technology, which is applied in chemical instruments and methods, magnetic separation, material magnetic variables, etc., can solve the problems of high power consumption, difficult installation and debugging, and high device cost of constant magnetic iron removal technology, and can detect iron Easy to implement, prolong the service life of equipment, determine and debug the effect of easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

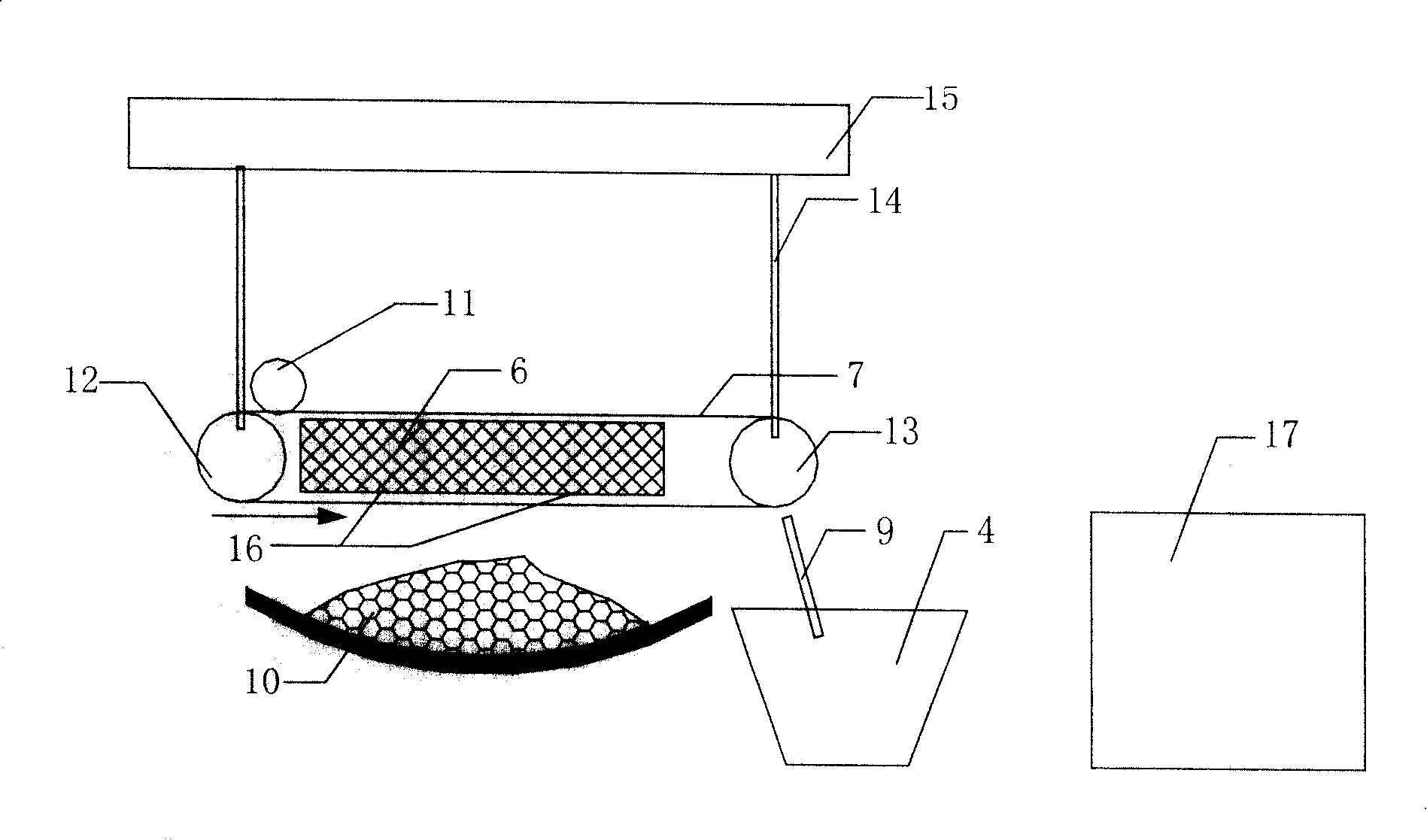

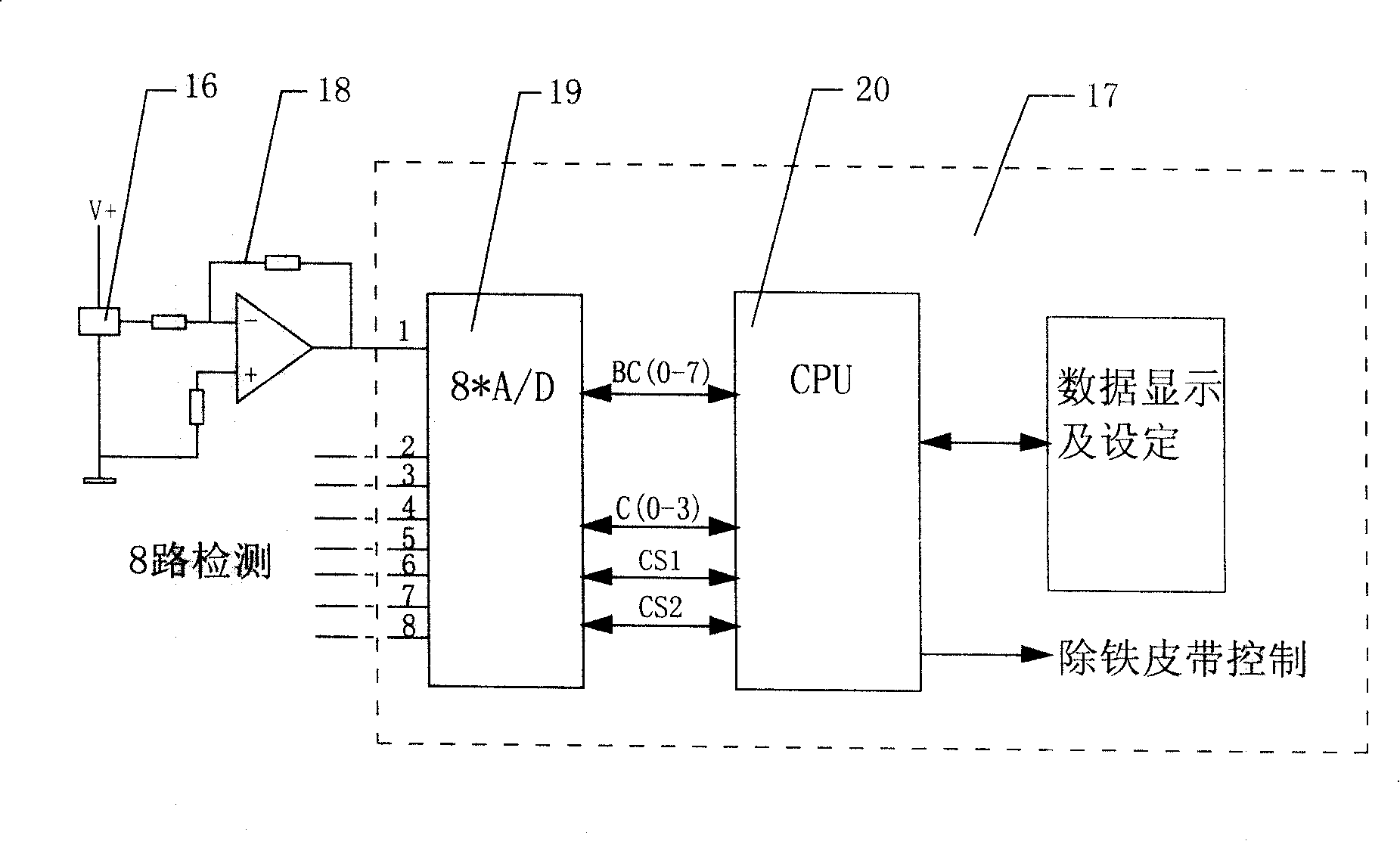

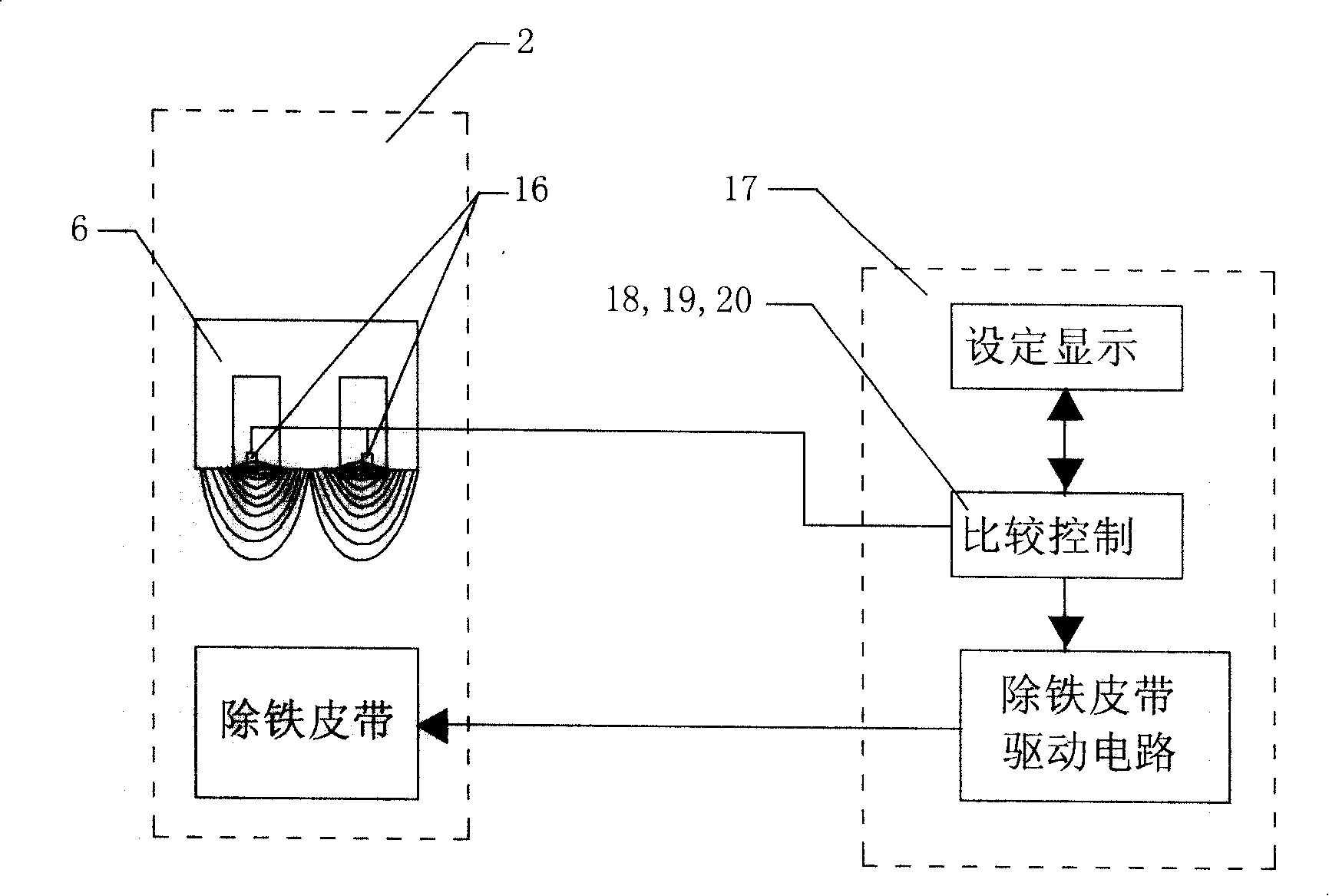

[0024] see figure 1 , figure 2 , a method in which a constant magnetic iron remover adopts a magnetic sensitive element group to detect iron pieces is to install a plurality of magnetic sensitive elements 16 between the magnetic poles of the constant magnetic iron remover 2 and the constant magnet 6, and the output of the magnetic sensitive element 16 is connected to a signal amplification circuit 18. For the analog signal directly processed by the comparison control circuit 20, the signal amplification circuit 18 is directly connected to the comparison control circuit 20. For comparison control circuit 20 to process digital signals, signal amplifying circuit 18 should be connected to signal input A / D conversion circuit 19; a plurality of detection circuit outputs that several magnetic sensitive elements 16 form are respectively connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com