Double helical ribbon multi-layer oar blade scraping cutter type stirrer

A scraper-type, double-ribbon technology is used in mixers with rotary stirring devices, chemical instruments and methods, and dissolution, etc., and can solve the problems of attaching to the side wall of the reactor, complex structure, and poor stirring effect. Uniform temperature, avoid liquid-liquid separation, prevent the effect of solid settling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

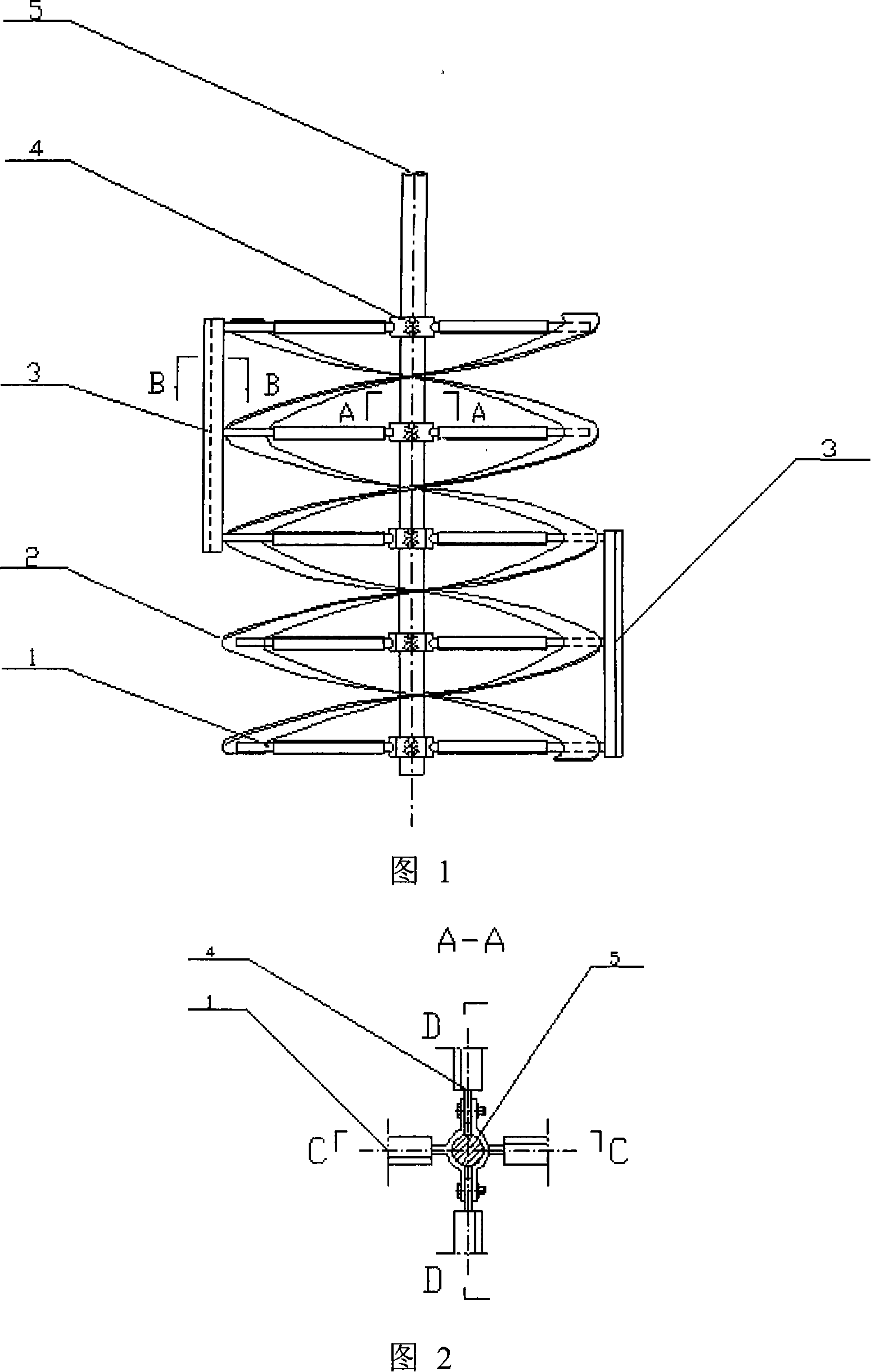

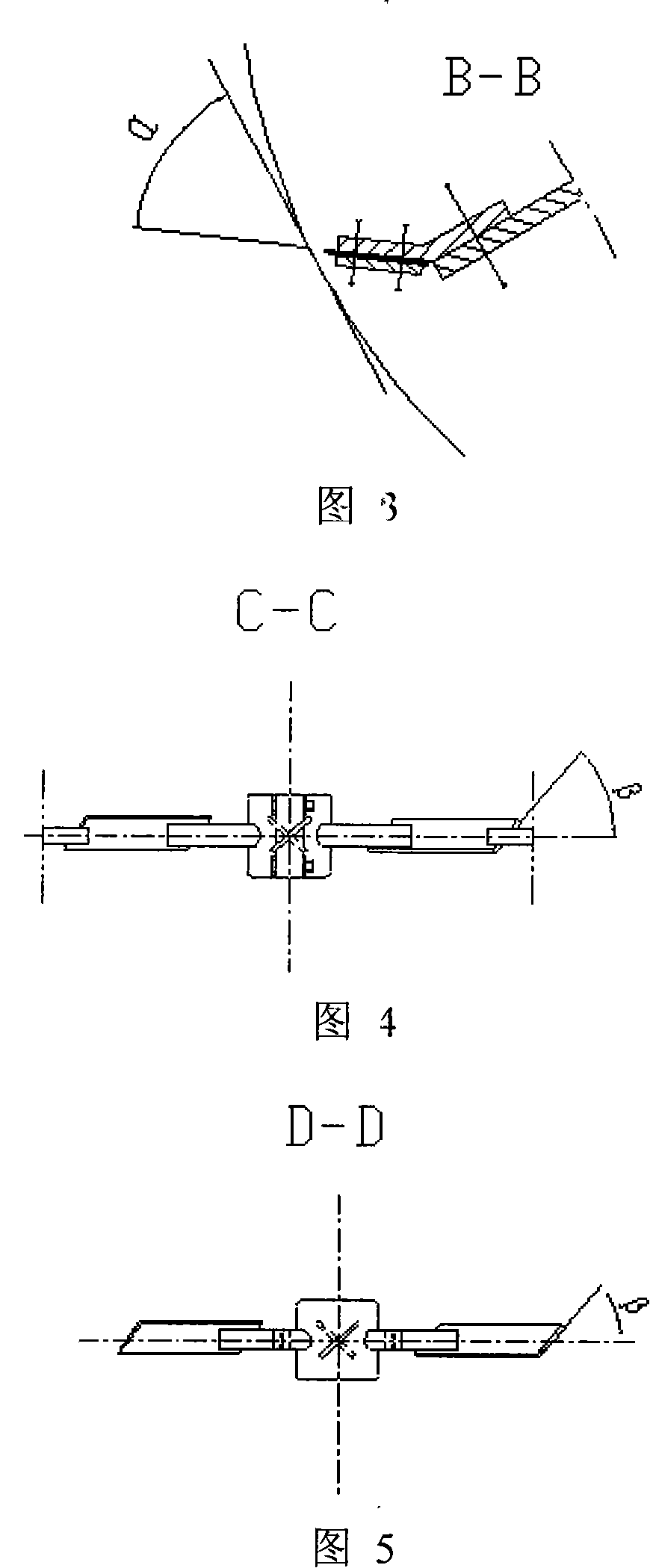

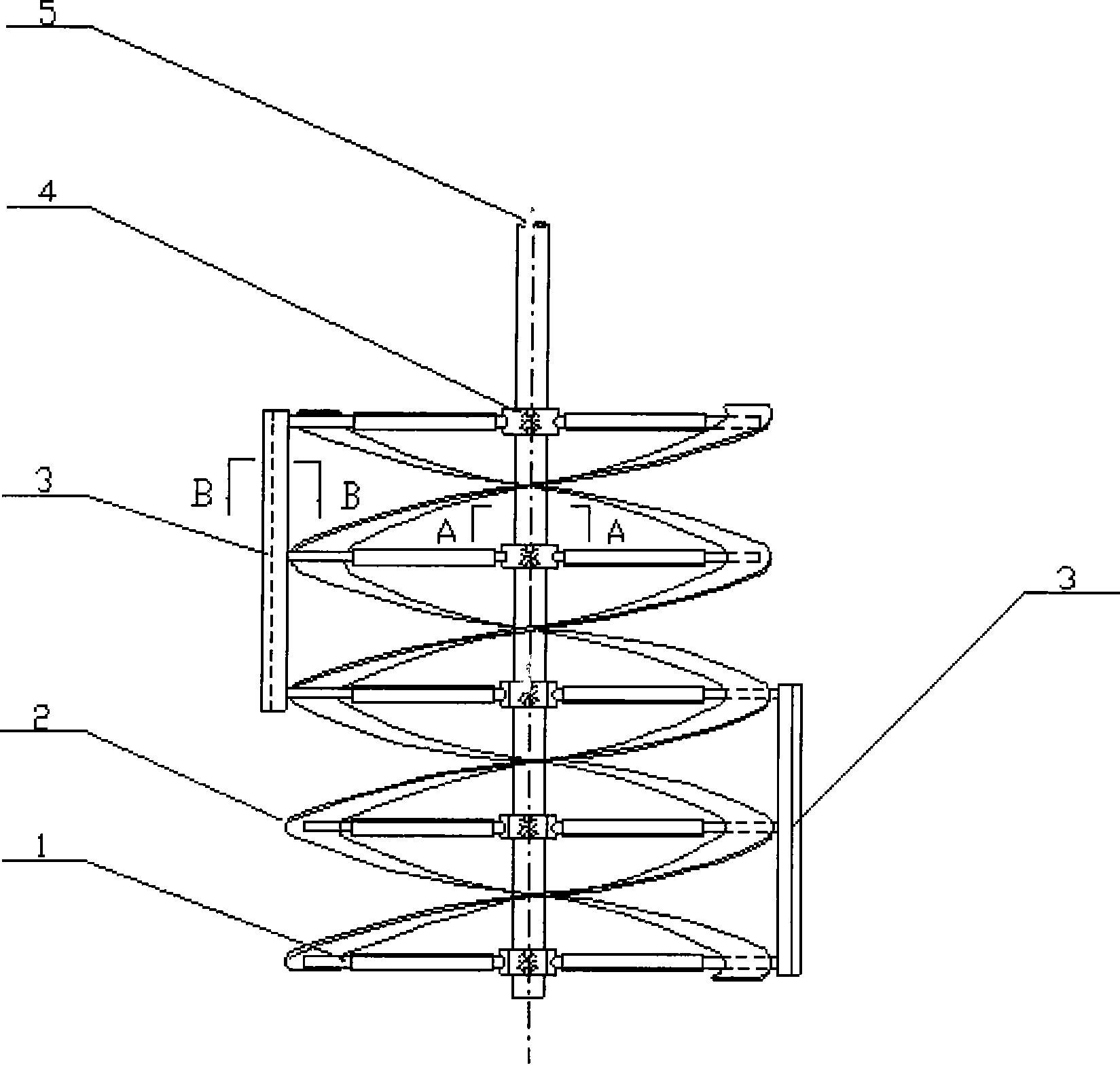

[0022] The agitator is composed of a supporting paddle 1, a ribbon 2, an independent paddle 4, a stirring shaft 5 and a flexible scraper 3. The supporting paddle 1 and the independent paddle 4 are symmetrically installed on the stirring shaft 5 respectively, and the support installed on each layer The inclination angle β between the paddle 1 and the independent paddle 4 and the radial horizontal section is 10°-45°, the ribbon 2 is connected with the stirring shaft 5 through the supporting paddle 1, and the flexible scraper 3 is symmetrically fixed on the ribbon 2, the angle α between the flexible scraper 3 and the wall is 20°-60°.

[0023] Load the material system to be mixed with a certain viscosity in the stirring tank, start the transmission equipment to drive the stirring shaft 5, the independent paddle 4 installed on the stirring shaft 5, the supporting paddle 1 and the screw connected to the stirring shaft 5 through the supporting paddle 1 Belt 2 turns. The material is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com