Drilling filling integrated drilling filling equipment and technique

A technology of drilling, irrigation and equipment, which is applied in the field of foundation treatment, can solve the problems of high hole failure rate, achieve significant economic benefits, improve the efficiency and quality of grouting construction, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

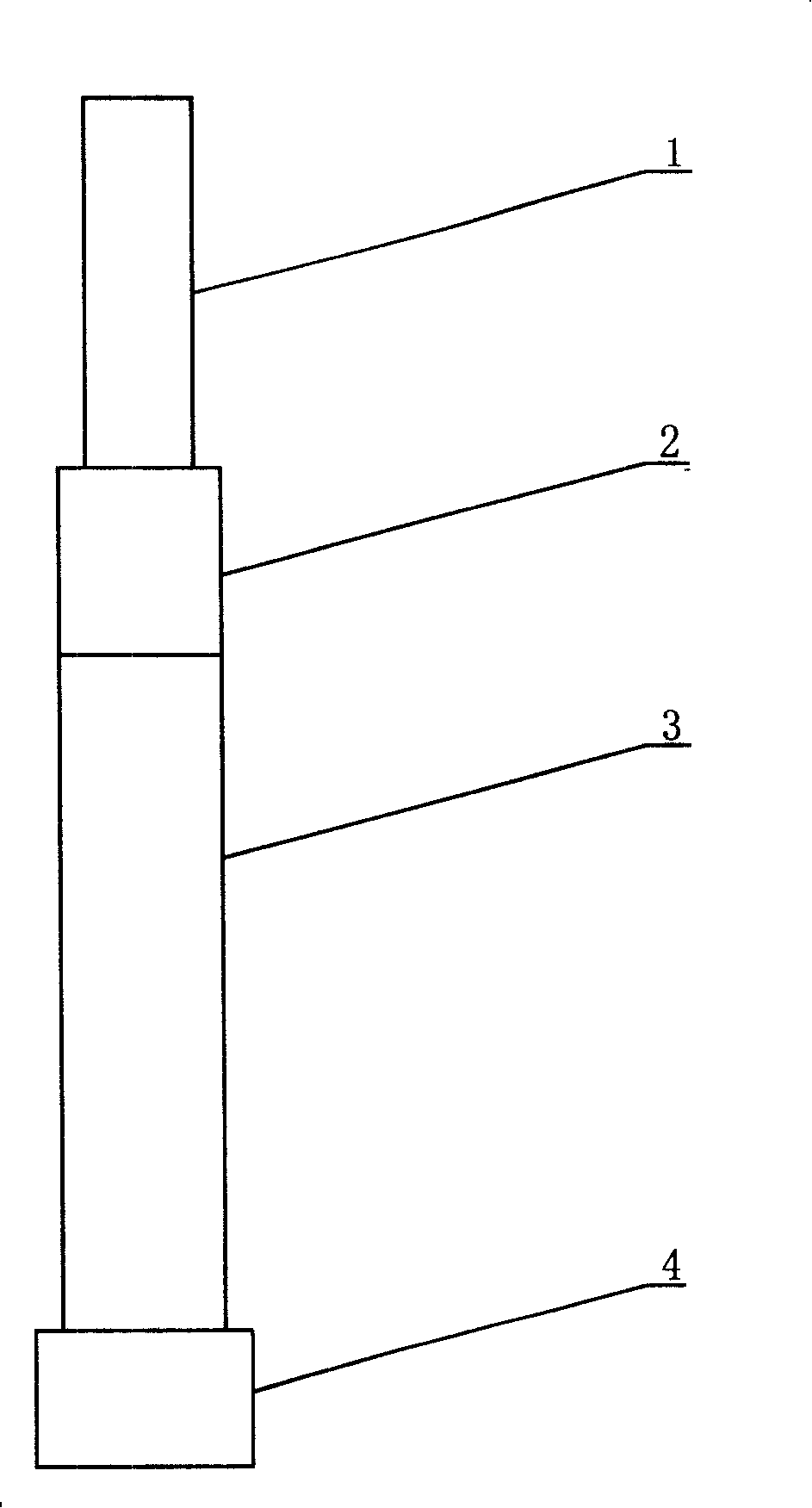

[0028] Such as figure 1 , 2 As shown, the drilling and irrigation integrated drilling and irrigation equipment has a driving drill pipe, a short drill pipe (1), a joint (2), a guide pipe (3) and a full-section drill bit (4), and the upper end of the short drill pipe (1) is connected to the The active drill pipe is connected with the drilling rig, the lower end is connected with the guide pipe (3) through the joint (2), and the lower end of the guide pipe (3) is connected with the full-section drill bit (4); the orifice pipe on the ground is connected with a rotary orifice sealer.

[0029] In the integrated drilling and irrigation equipment, the guide pipe (3) used to guide the drilling is a thick-walled steel pipe.

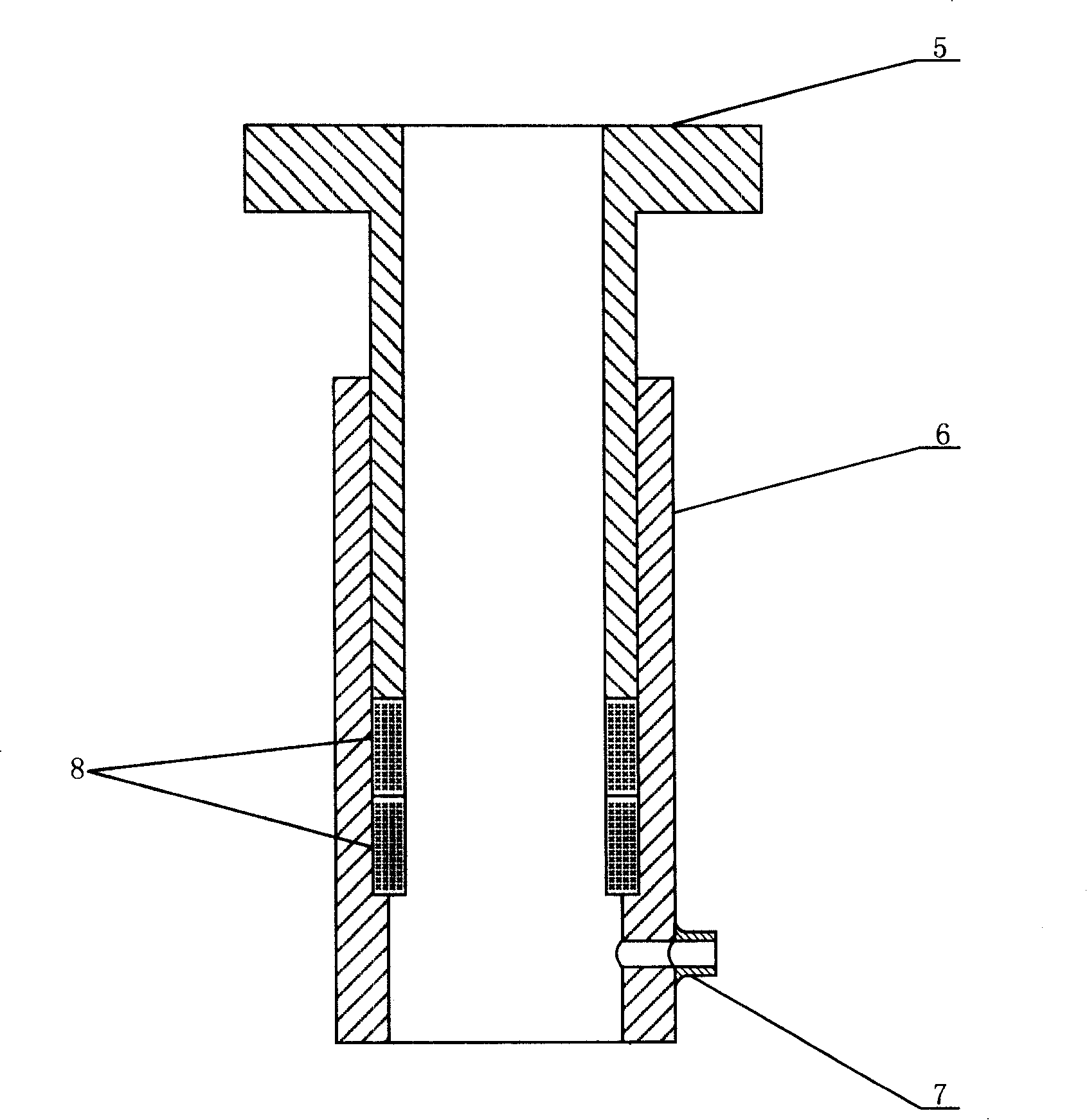

[0030] The drill-irrigation integrated drilling-irrigation equipment, its rotary orifice sealer is composed of a gland (5), an outer jacket (6) and a sealing ring (8), and the gland (5) is threadedly connected with the outer jacket (6) , the lower end of the gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com