Underwater bridge foundation construction method

A construction method and technology of bridge foundation, which can be applied in the direction of infrastructure engineering and construction, and can solve the problems of increasing construction cost, long processing period and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

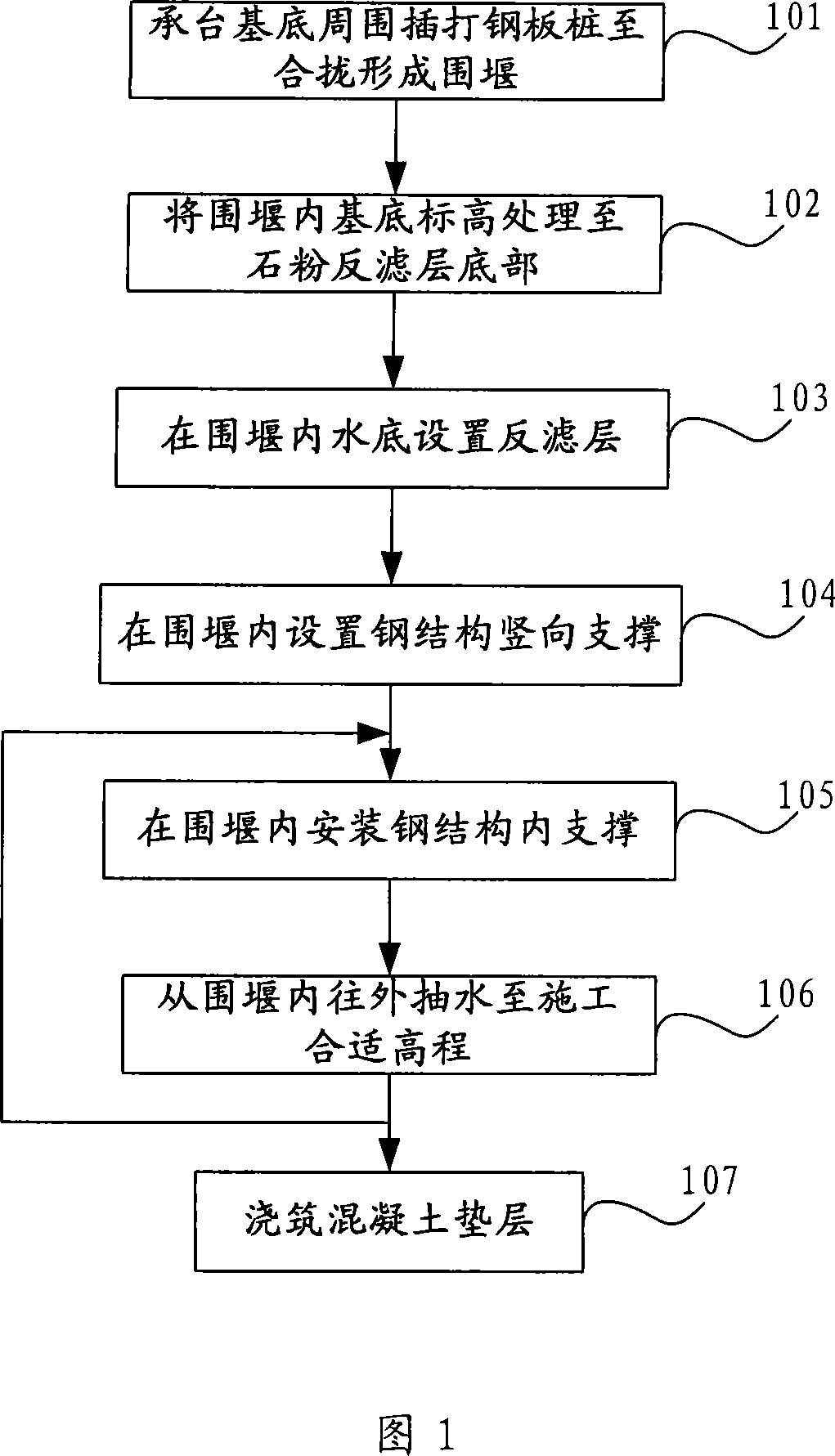

Method used

Image

Examples

Embodiment Construction

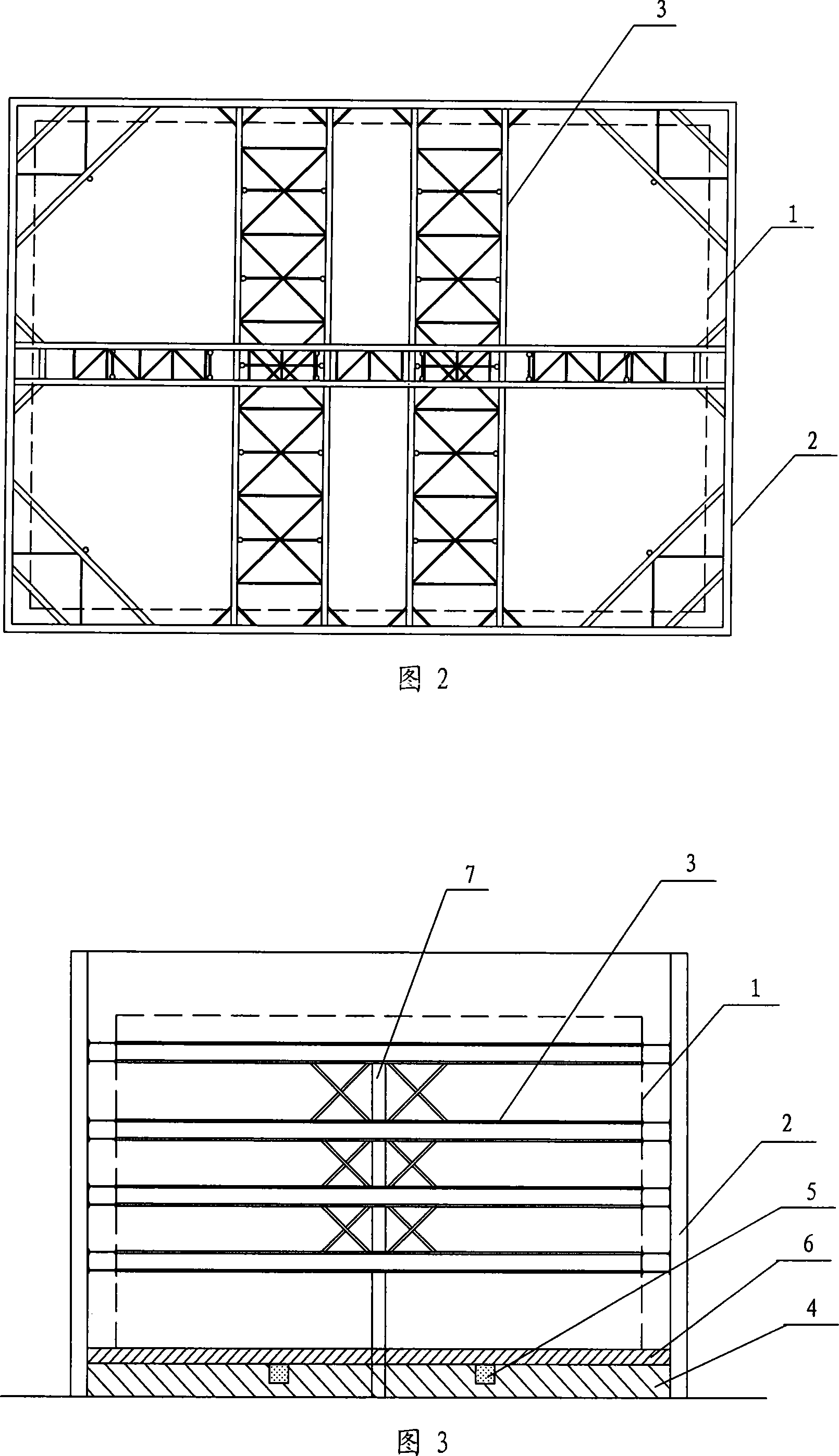

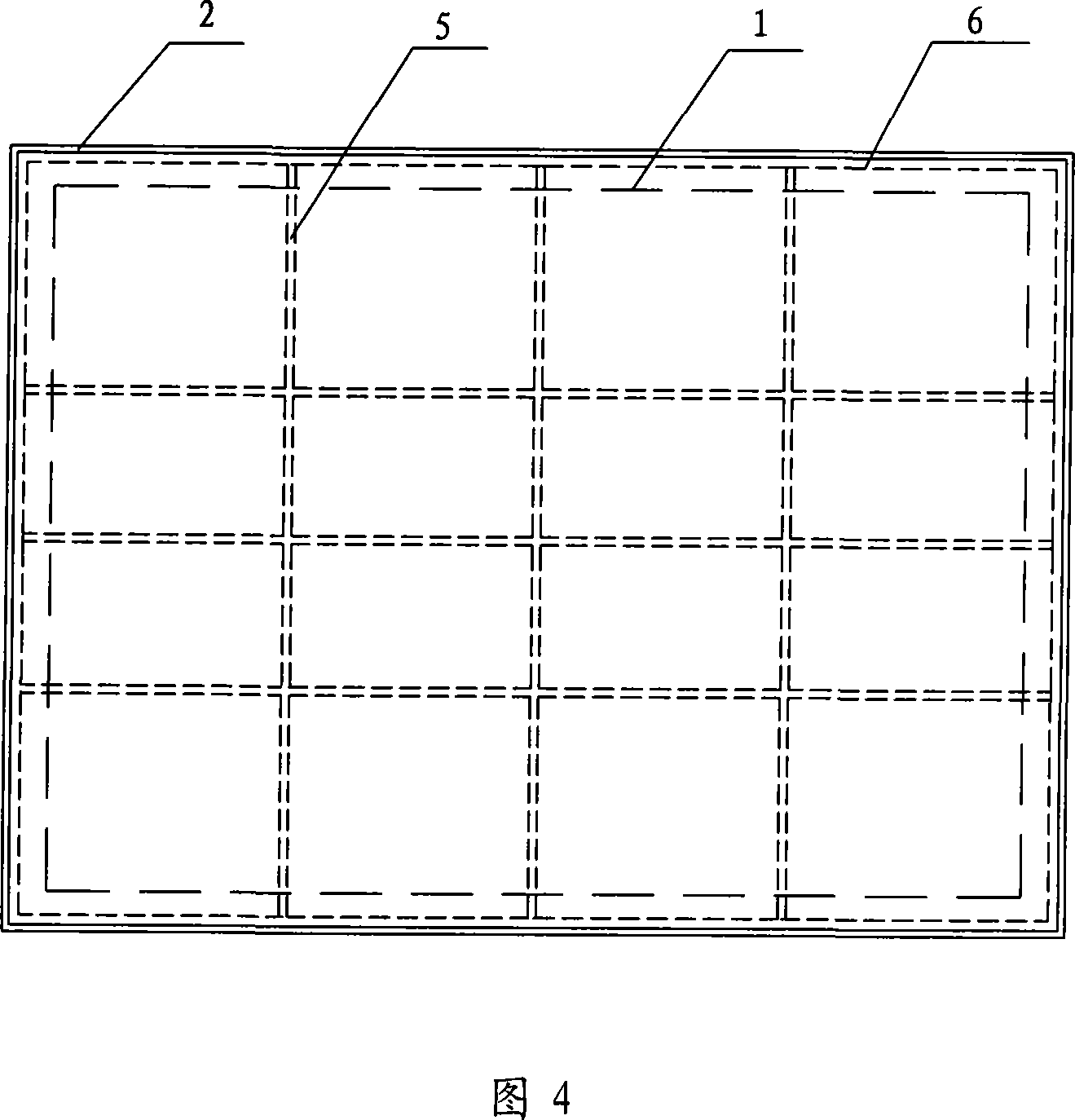

[0033] The bridge foundation construction method in the water of the present invention adopts the unsealed construction scheme of the large-volume single-wall steel sheet pile cofferdam in deep water. After analyzing the anti-seepage stability of the unsealed system of the cofferdam, the permeability coefficient in the sand layer is 1.0×10 -2 cm / s, and the rock permeability coefficient is 4.0×10 -4 cm / s, the converted permeability coefficient of steel sheet piles under the river bed is 5.0×10 -5 In the case of cm / s, the seepage flow of the unsealed cofferdam is greater than the seepage flow of the concrete backseal, the water pressure is less than half of that of the concrete backseal, and the safety factor is twice or even more than that of the concrete backseal scheme. The analysis shows that because the steel sheet pile cofferdam system is generally a flexible support structure, it cannot completely seal the bottom under the influence of tide fluctuation and ship movement. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com