Integrated molding house construction method

An integrated, house-based technology, which is applied in construction, building components, building structures, etc., can solve problems such as long construction time, long construction period, and non-environmental protection, and achieve the effect of less time consumption, short construction period, and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

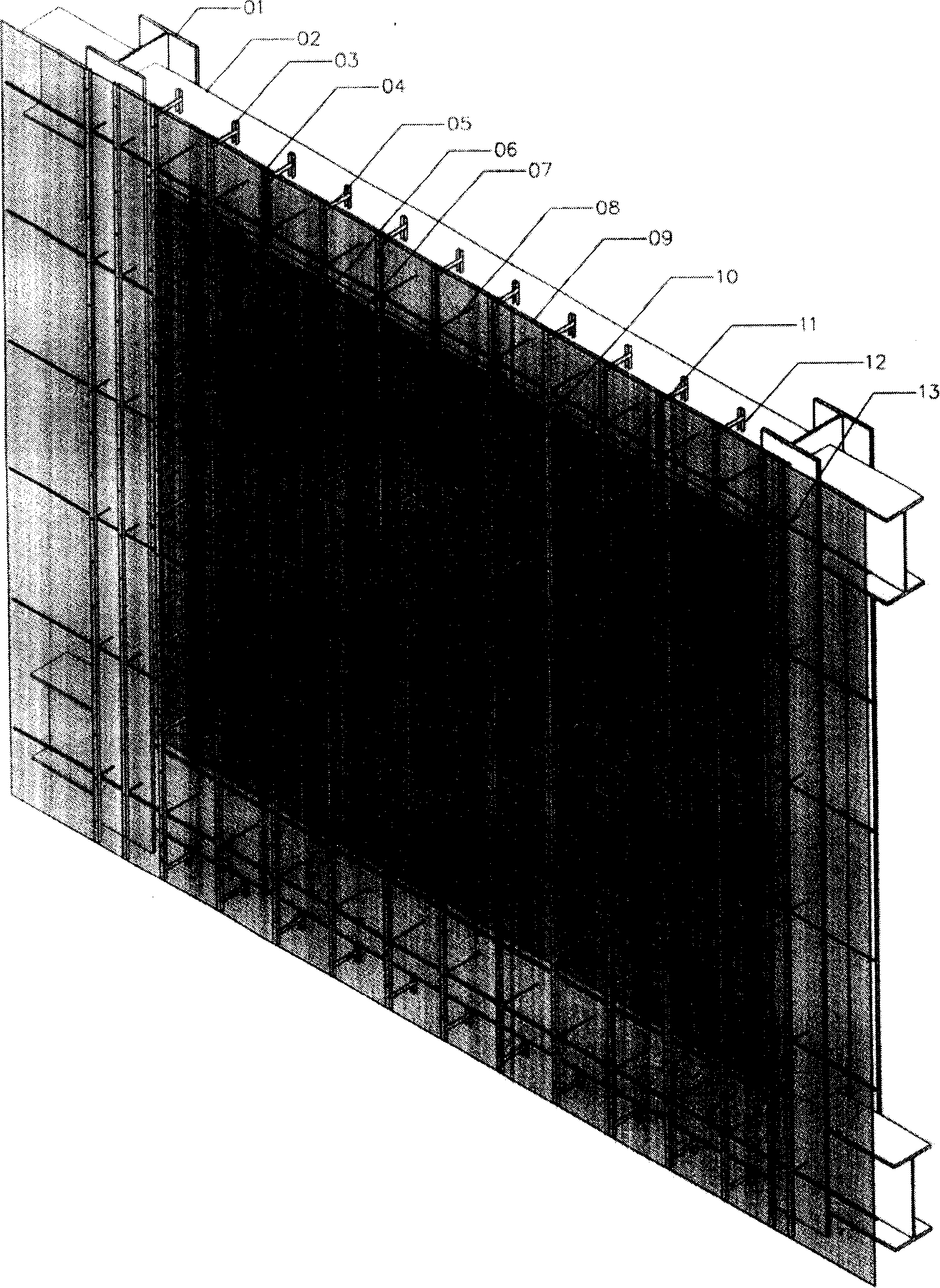

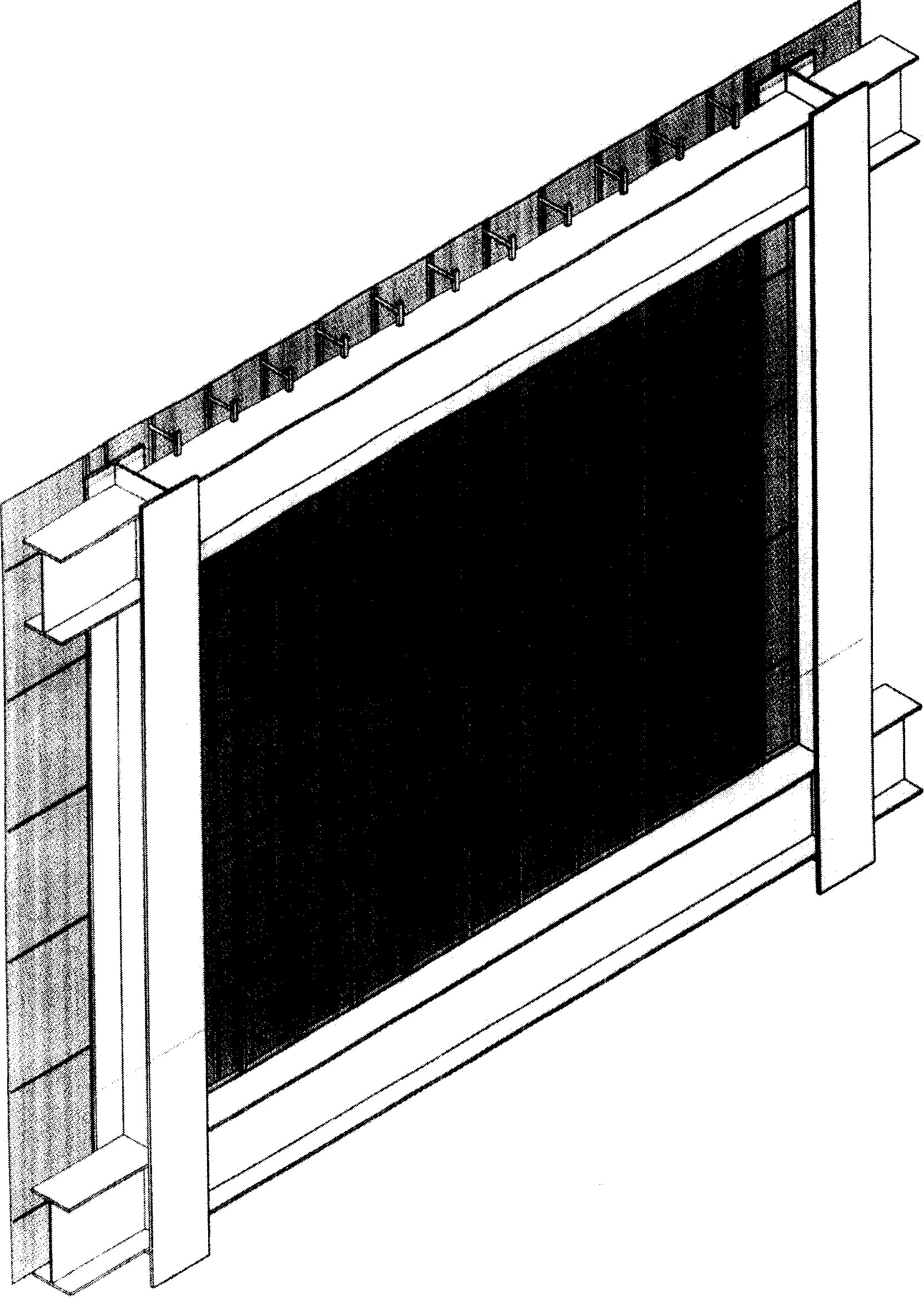

[0052] The construction method of the integrally formed house of the present invention comprises the following steps:

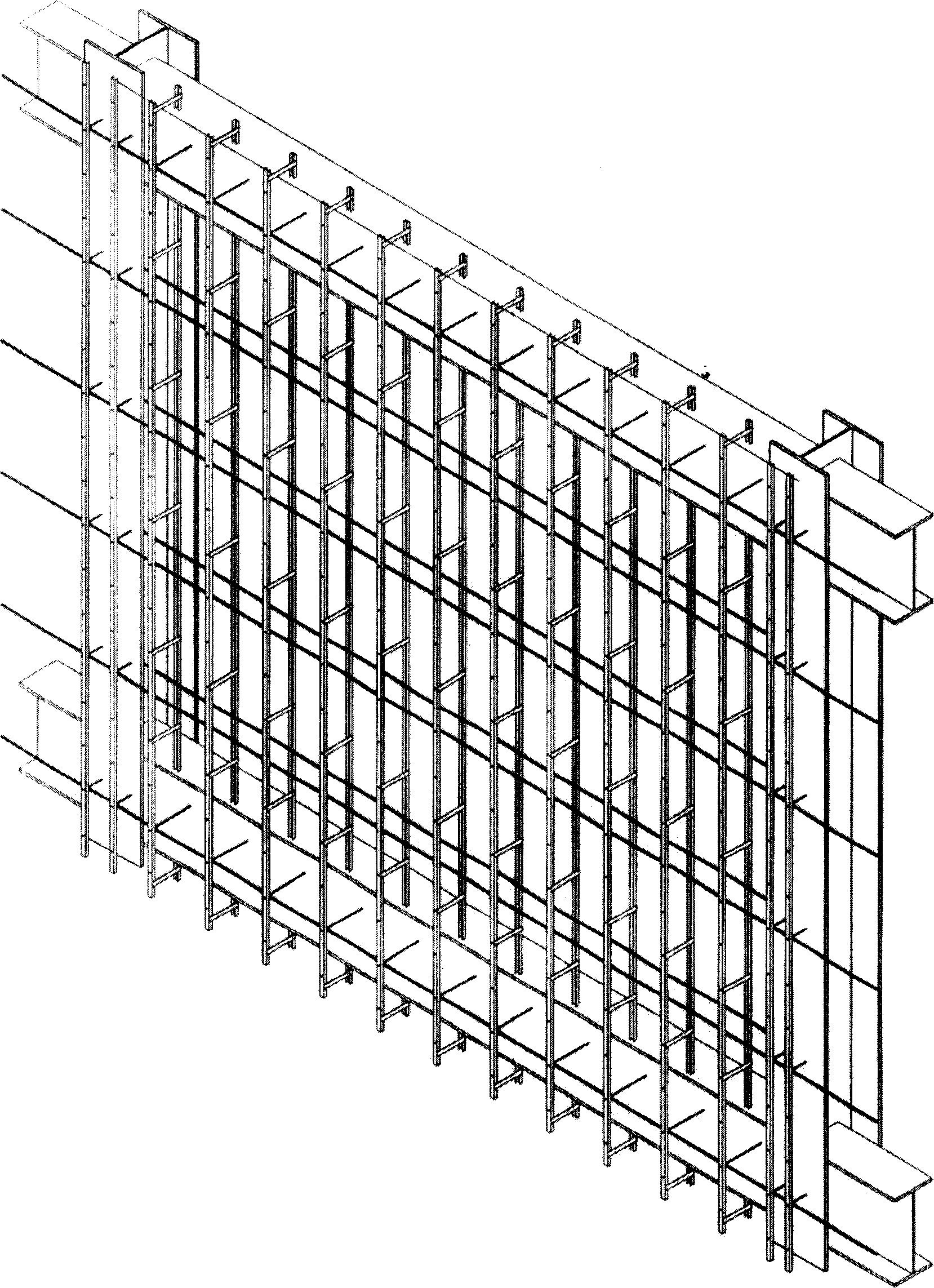

[0053] A. According to the traditional construction method, the order of excavation, footing, ground beam, floor, column, beam and plate is laid to complete the entire steel frame and floor plate;

[0054] B. Fix the small U-shaped steel as the skeleton, take the plane surrounded by the outer column and the outer column of the building, and the side beam and the side beam as the unit. According to the designed wall thickness, the outer wall is 10 cm away from the outer edge of the beam and column surface. The inner wall is 5 cm into the beam column surface; the non-load-bearing wall with a thickness of less than 15 cm requires at least the outer edge of the beam column surface to be wrapped in the wall; the horizontal spacing of small U-shaped steel is 28 cm, and the horizontal direction is spot-welded with bamboo steel bars to form fixed bars. The dismantlin...

Embodiment 2

[0060] The construction method of the integrally formed house of the present invention comprises the following steps:

[0061] A. According to the traditional construction method, the order of excavation, footing, ground beam, floor, column, beam and plate is laid to complete the entire steel frame and floor plate;

[0062] B. Fix the small U-shaped steel as the skeleton, take the plane surrounded by the outer column and the outer column of the building, and the side beam and the side beam as the unit. According to the designed wall thickness, the outer wall is 12 cm away from the outer edge of the beam and column surface. The inner wall is 6 cm into the beam column surface; the non-load-bearing wall with a thickness of less than 15 cm requires at least the outer edge of the beam column surface to be wrapped in the wall; the horizontal spacing of small U-shaped steel is 30 cm, and the horizontal direction is spot-welded with bamboo steel bars to form fixed bars; The dismantlin...

Embodiment 3

[0068] The construction method of the integrally formed house of the present invention comprises the following steps:

[0069] A. According to the traditional construction method, the order of excavation, footing, ground beam, floor, column, beam and plate is laid to complete the entire steel frame and floor plate;

[0070] B. Fix the small U-shaped steel as the skeleton, take the plane surrounded by the outer column and the outer column of the building, and the side beam and the side beam as the unit. According to the designed wall thickness, the outer wall is 14 cm away from the outer edge of the beam and column surface. 7 cm into the beam column surface of the inner wall is the minimum thickness requirement of the load-bearing wall; the non-load-bearing wall with a thickness of less than 15 cm requires at least the outer edge of the beam column surface to be wrapped in the wall; the horizontal spacing of small U-shaped steel is 32 cm, and the horizontal direction is made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com