Laser angle interferometry system possessing standard angle rotating platform and its measurement method

A standard angle and angle technology, applied in the field of laser interferometry angle measurement system, can solve the problems of initial zero position error, limited application range, large measurement error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

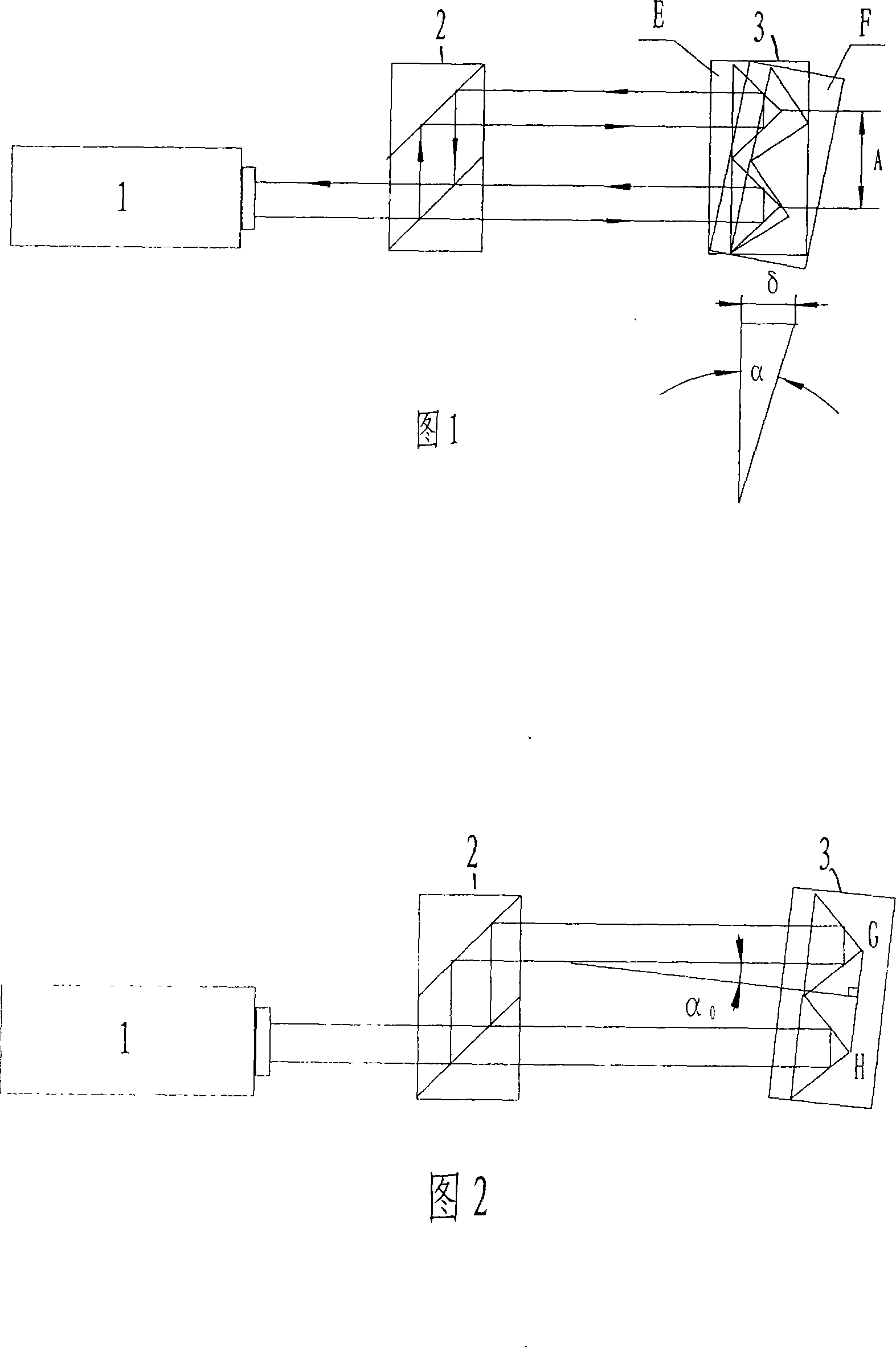

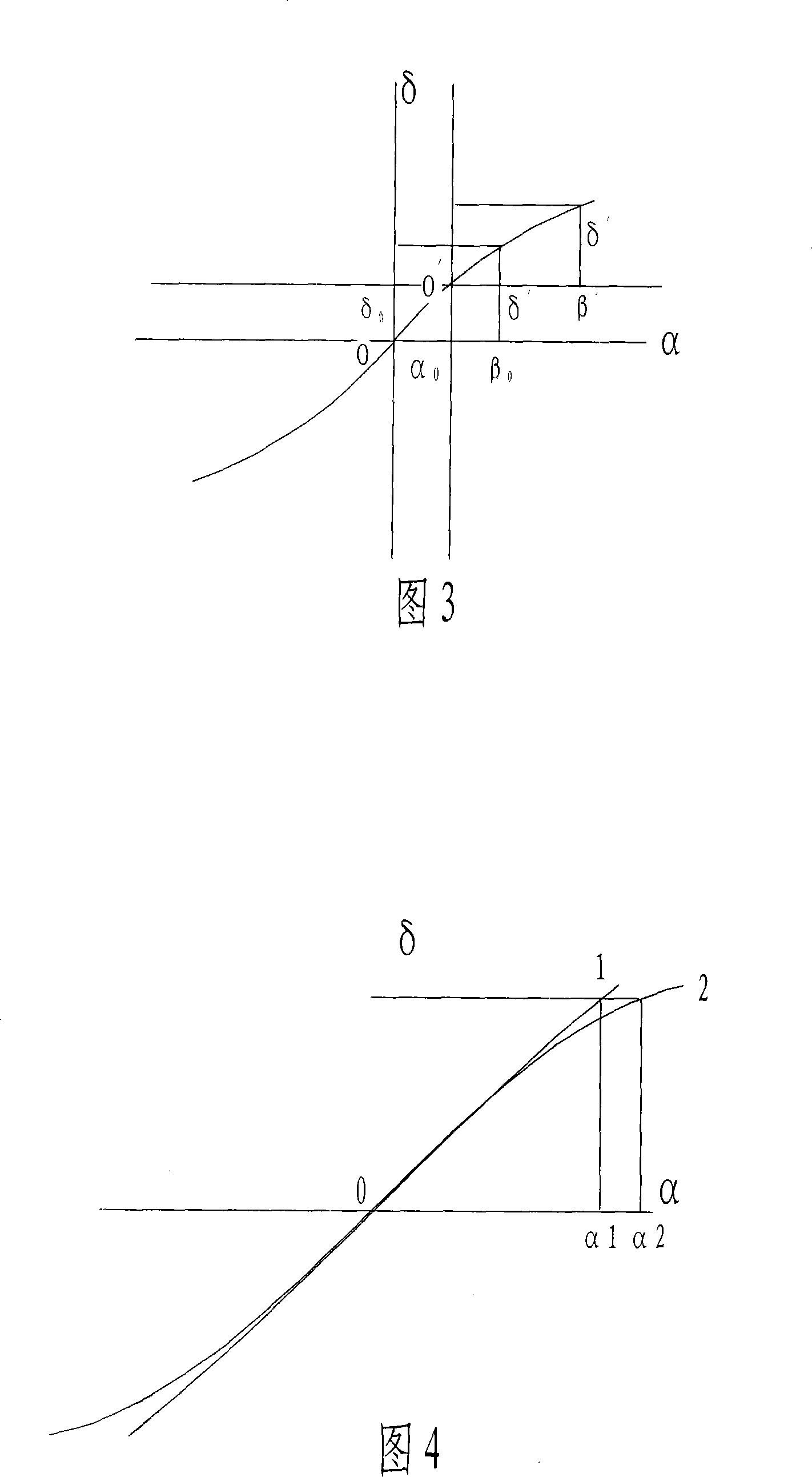

Method used

Image

Examples

Embodiment 1

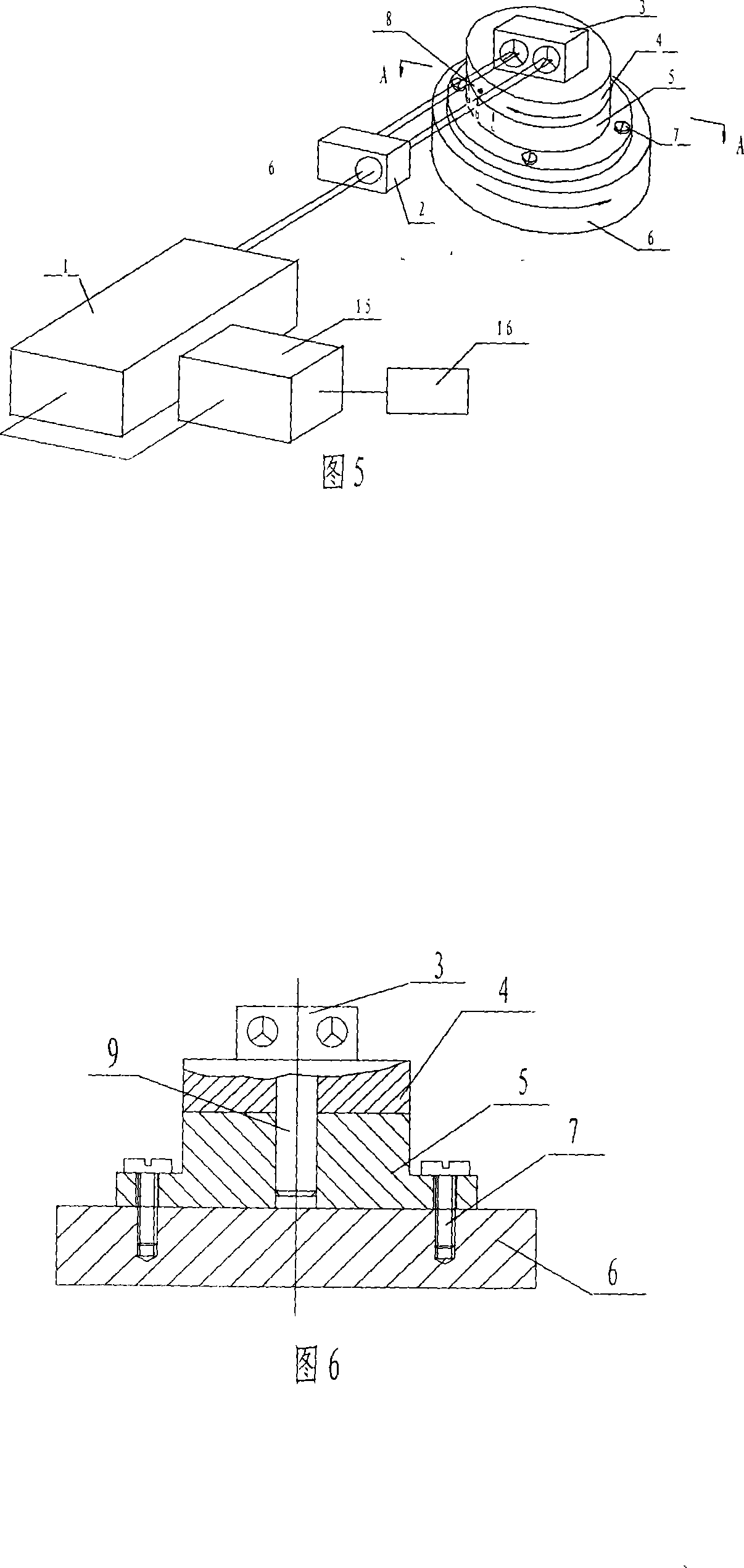

[0071] Embodiment 1: A laser angle interferometry system with a standard angle turntable measures any angle, the steps are as follows:

[0072] (1) Rotate the turntable upper plate 4 so that the angle mark 8 on the side circumference points to the mark line b between a and c on the turntable chassis 5 side circumference, adjust the turntable upper plate 4, the turntable chassis 5 and the angle reflector 3 as a whole , so that the surface of the angle reflector 3 is perpendicular to the incident laser beam, fasten the turntable chassis 5 and the measured turntable 6, and the computer clears the system and sets the angle reflector 3 at the zero position clockwise. Laser angle interferometer display It is "+"; (2) Calibration starts, rotate the upper disc 4 of the turntable until the angle mark 8 on its side circumference points to the position of the mark line a on the side circumference of the turntable chassis 5 and locks it, and the computer records the reading ρ of the laser ...

Embodiment 2

[0086] Embodiment 2: A laser angle interferometry system with a standard angle turntable detects the positional accuracy of the CNC turntable, the steps are as follows:

[0087] The installation of the system is the same as that in Figure 5. The tested turntable 6 is the tested CNC turntable. The detection interval of the CNC turntable is selected as r, and r is smaller than the total range of the laser angle interferometer. The specific operation steps are as follows:

[0088] Steps (1)-(3) are the same as in Embodiment 1, which is a calibration process. Measurement starts from step (4):

[0089] (4) Rotate the upper plate 4 of the turntable until the angle mark 8 on its side circumference points to the position of the mark line b on the side circumference of the turntable chassis 5 and locks it. The computer clears the system and sets the angle mirror 3 clockwise at the zero position. The direction of the laser angle interferometer is displayed as "+"; (5) Rotate the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com