Ultrasonics wind velocity indicator and method for measuring wind velocity and wind direction by ultrasonic

An ultrasonic and anemometer technology, used in fluid velocity measurement, velocity/acceleration/impact measurement, measurement devices, etc., can solve the problems of low measurement accuracy, short service life, and large environmental impact, saving maintenance costs and improving measurement. The effect of precision and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

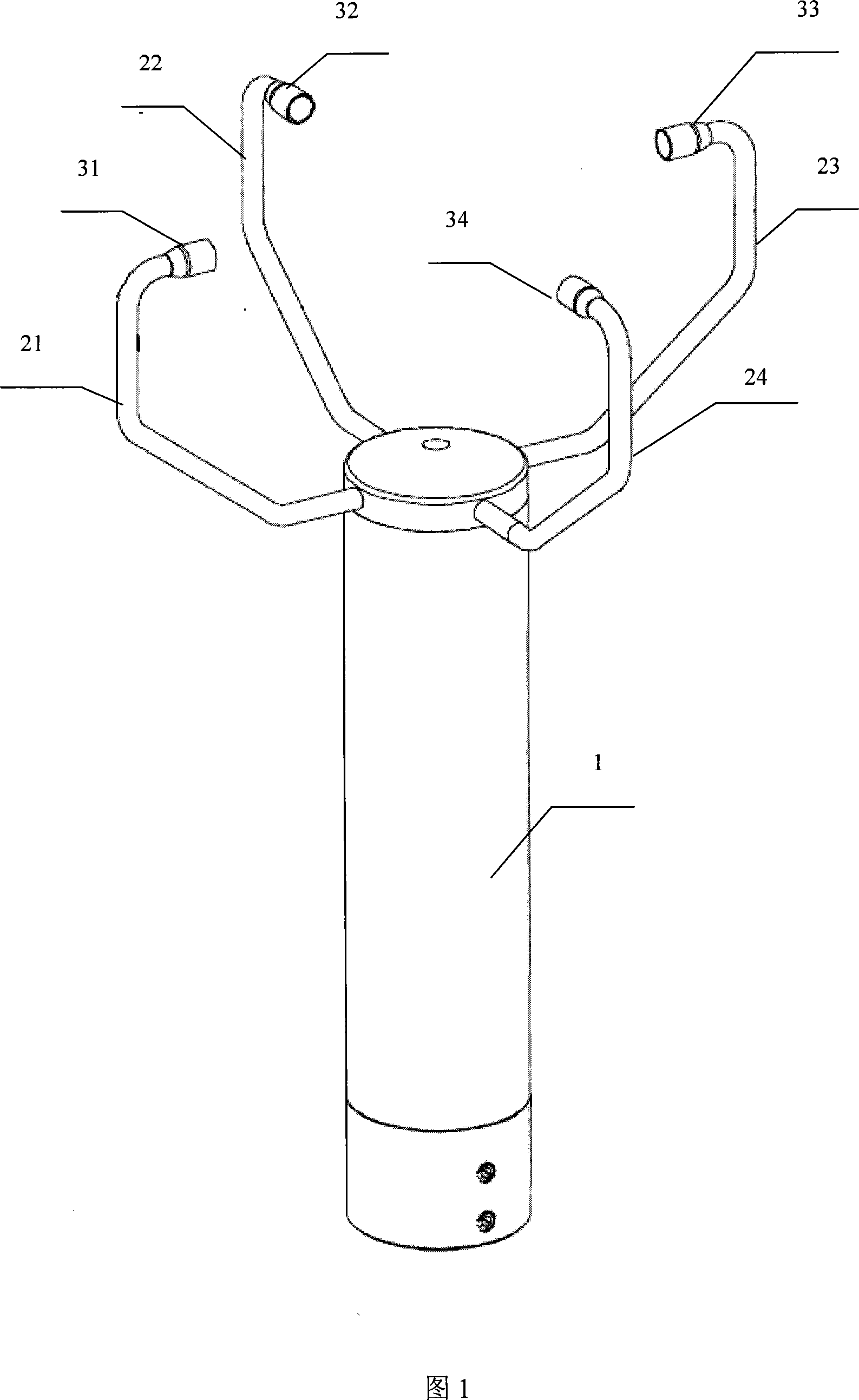

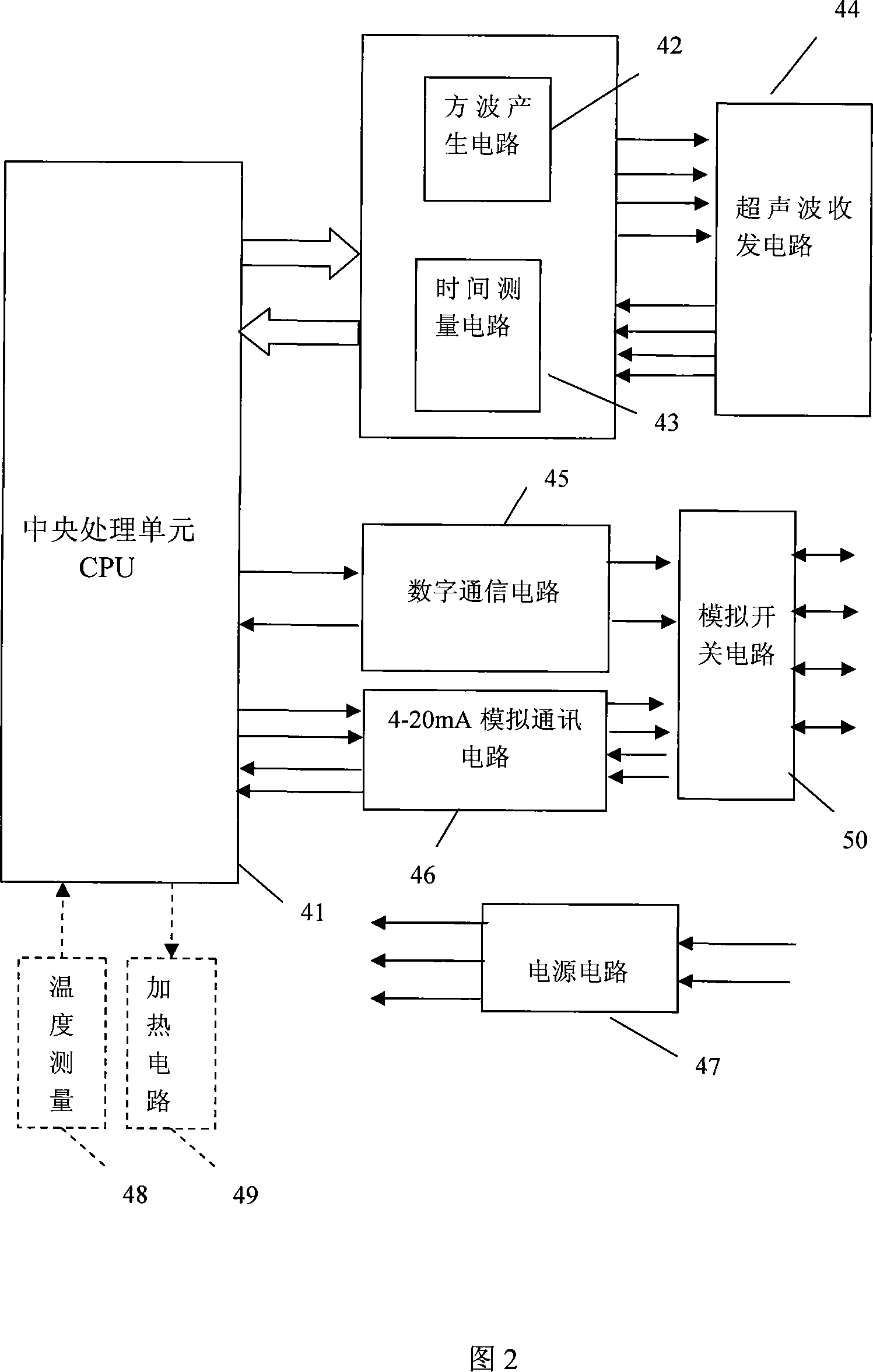

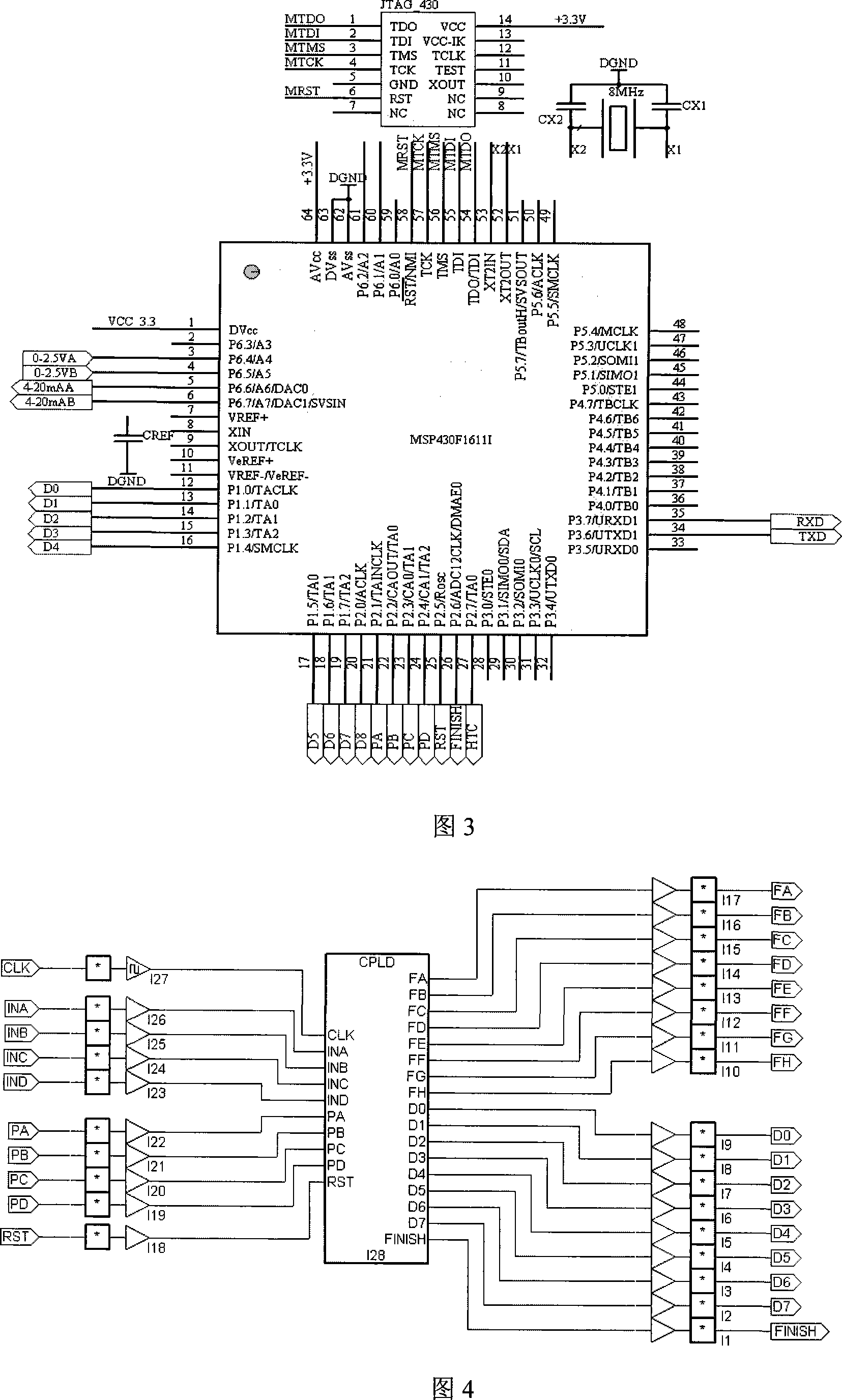

[0031] Referring to Fig. 1, the ultrasonic anemometer provided by the embodiment of the present invention includes a base 1, a control circuit board and four measuring arms mounted on the base: a first measuring arm 21, a second measuring arm 22, a third measuring arm 23 and a Four measuring arms 24 . The base 1 is a cylinder, and the four measuring arms are respectively installed on the same horizontal plane at the top of the base 1, and the adjacent measuring arms form an included angle of 90 degrees in turn. The measuring arm is formed by bending a hollow stainless steel tube, and an ultrasonic transmitting / receiving probe composed of an ultrasonic sensor is installed on the top of each measuring arm, respectively: the first ultrasonic transmitting / receiving probe 31, the second ultrasonic transmitting / receiving probe The receiving probe 32 , the third ultrasonic transmitting / receiving probe 33 and the fourth ultrasonic transmitting / receiving probe 34 . The first ultrasoni...

Embodiment 2

[0050] Figure 11 shows the schematic diagram of the method of using ultrasonic anemometer to measure wind speed and wind direction with ultrasonic waves. This method uses the time difference method to measure the time difference between the forward and reverse directions of the ultrasonic wave propagating along the air and arrive at the receiving end to calculate the air flow velocity. .

[0051] Through the ultrasonic anemometer provided in Example 1, the ultrasonic transmitting / receiving probe is used as the ultrasonic transmitting / receiving device to describe in detail the method for measuring wind speed and wind direction provided by the embodiment of the present invention, which specifically includes the following steps, see Figure 1 and Figure 12:

[0052] Step 200: the first ultrasonic transmitting / receiving probe 31 sends ultrasonic waves to the third ultrasonic transmitting / receiving probe 33, and measures the propagation time of ultrasonic waves between the first ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com