Voltage-variable photovoltaic system maximal power tracing control method adapting to weather status

A technology of maximum power tracking and weather conditions, applied in the field of optoelectronics, can solve the problems of low tracking efficiency, no reference, poor adaptability, etc., and achieve the effect of fast tracking speed, high cost performance and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

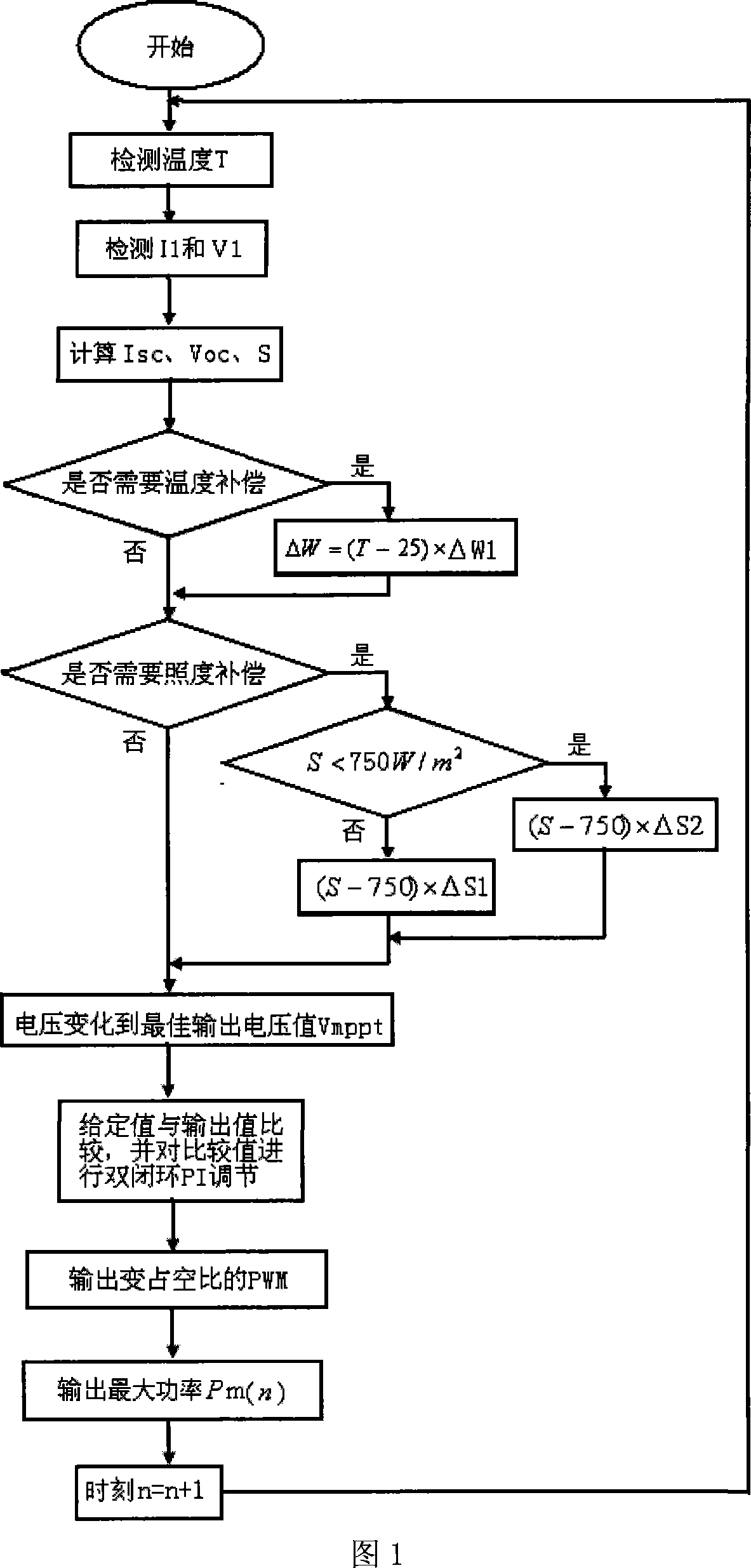

[0023] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings: this embodiment is carried out under the premise of the technical solution of the present invention, and detailed implementation methods and processes have been provided, but the protection scope of the present invention is not limited to the following implementation example.

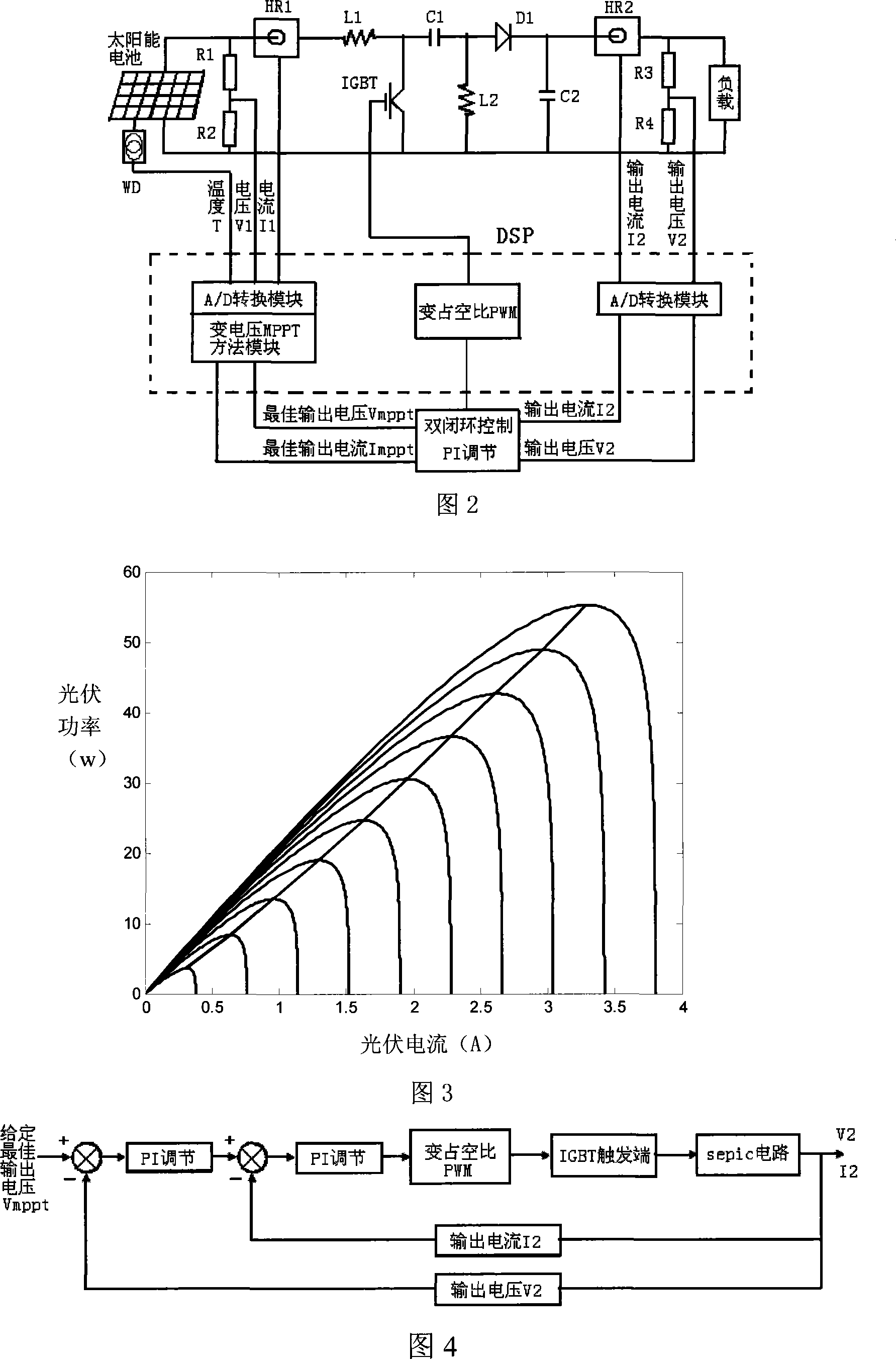

[0024] As shown in Figure 2, it is a photovoltaic MPPT system that implements the method of this embodiment, wherein: the first perforated Hall current sensor HR1 and the first perforated Hall current sensor HR2 are used to detect the solar cell output current I1 and the load terminal output respectively The current I2, the model adopts the HKA50-YP type of the HKA-YP series Hall current sensor of Beijing Huazhi Xingyuan Technology Co., Ltd., and the measurement current range is 0-150A; the solar cell output voltage V1 and The output voltage value of the load terminal is V2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com