Cascaded power bus bar used for magnetic suspending train wave cutter

A technology for magnetic levitation trains and choppers, which is applied in the installation of busbars, cables, electrical components, etc., and can solve the problem of affecting the normal operation of the levitation chopper of maglev trains, affecting the reliability of the levitation chopper of maglev trains, and occupying wires. The internal space of the chassis and other issues can be reduced to reduce the proximity effect, reduce the number of connecting lines, and improve system reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

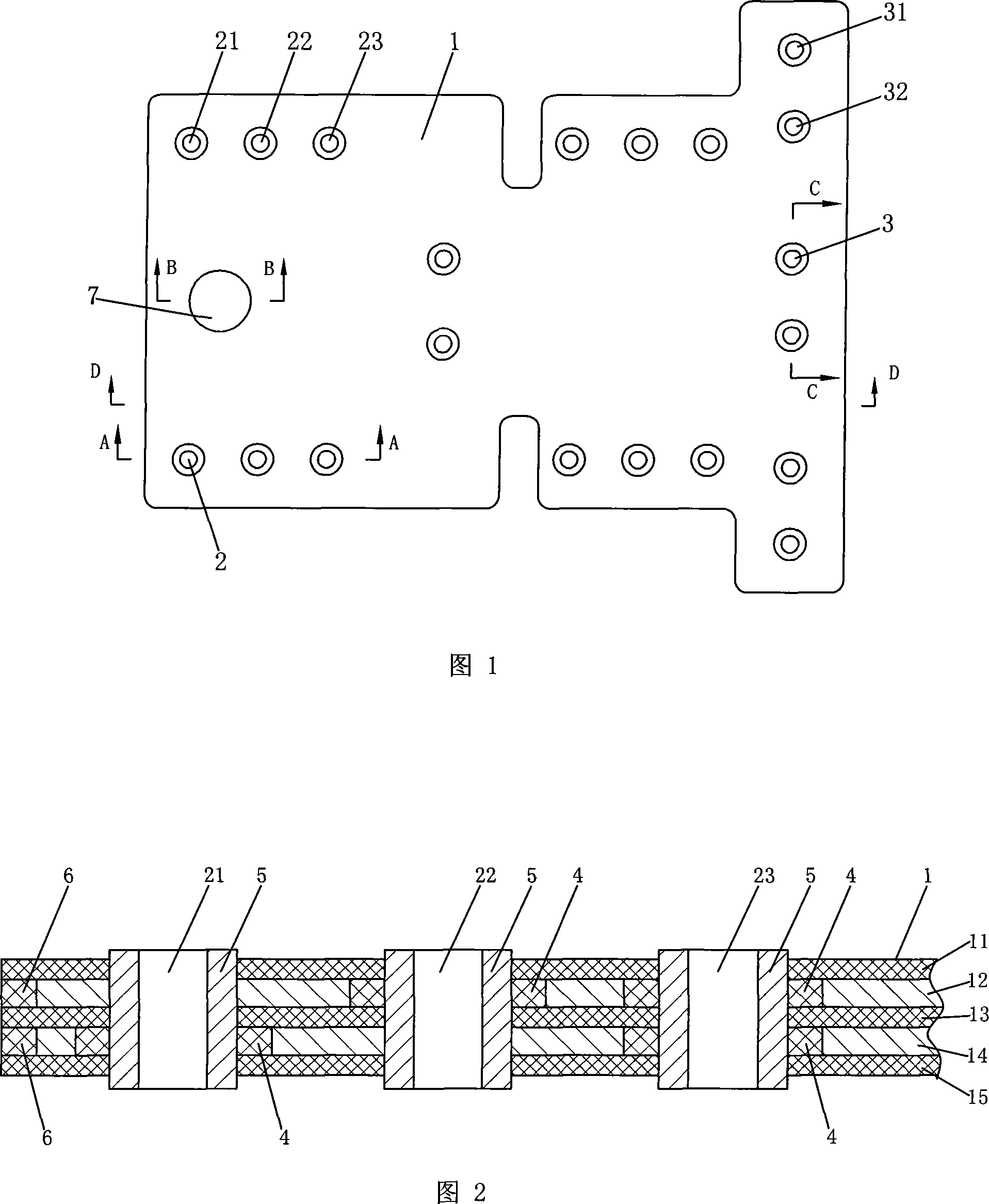

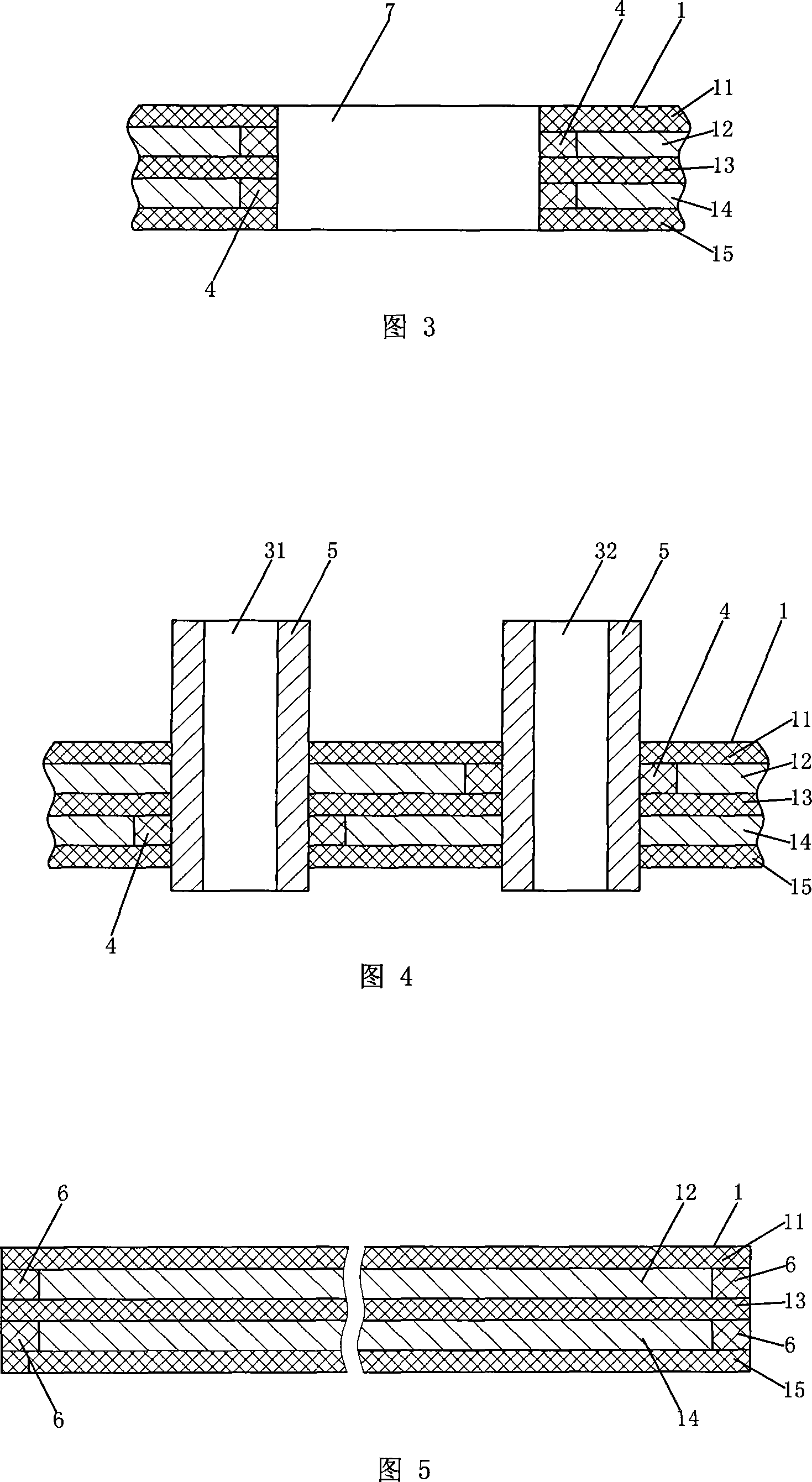

[0023] Fig. 1~5 shows, a kind of specific embodiment of the present invention: a kind of lamination power bus bar that is used for the levitation chopper of maglev train, insulating top plate 11, conductive positive plate 12, insulating partition plate 13, conductive The negative electrode plate 14 and the insulating bottom plate 15 are stacked and bonded in sequence to form the motherboard 1 .

[0024] Figures 1, 2, and 4 show that the motherboard 1 of this example is provided with a power terminal connection hole group 2 adapted to the power terminal of the power module, including the positive polarity hole 21 of the power terminal, the negative polarity hole 22 of the power terminal and the power terminal. The terminal output hole 23; the motherboard 1 is also provided with a positive pole hole 31 and a negative pole hole 32, which form a connection hole pair 3. All connection holes on the motherboard are tightly embedded with conductive rings 5, and an insulating ring 4 is...

Embodiment 2

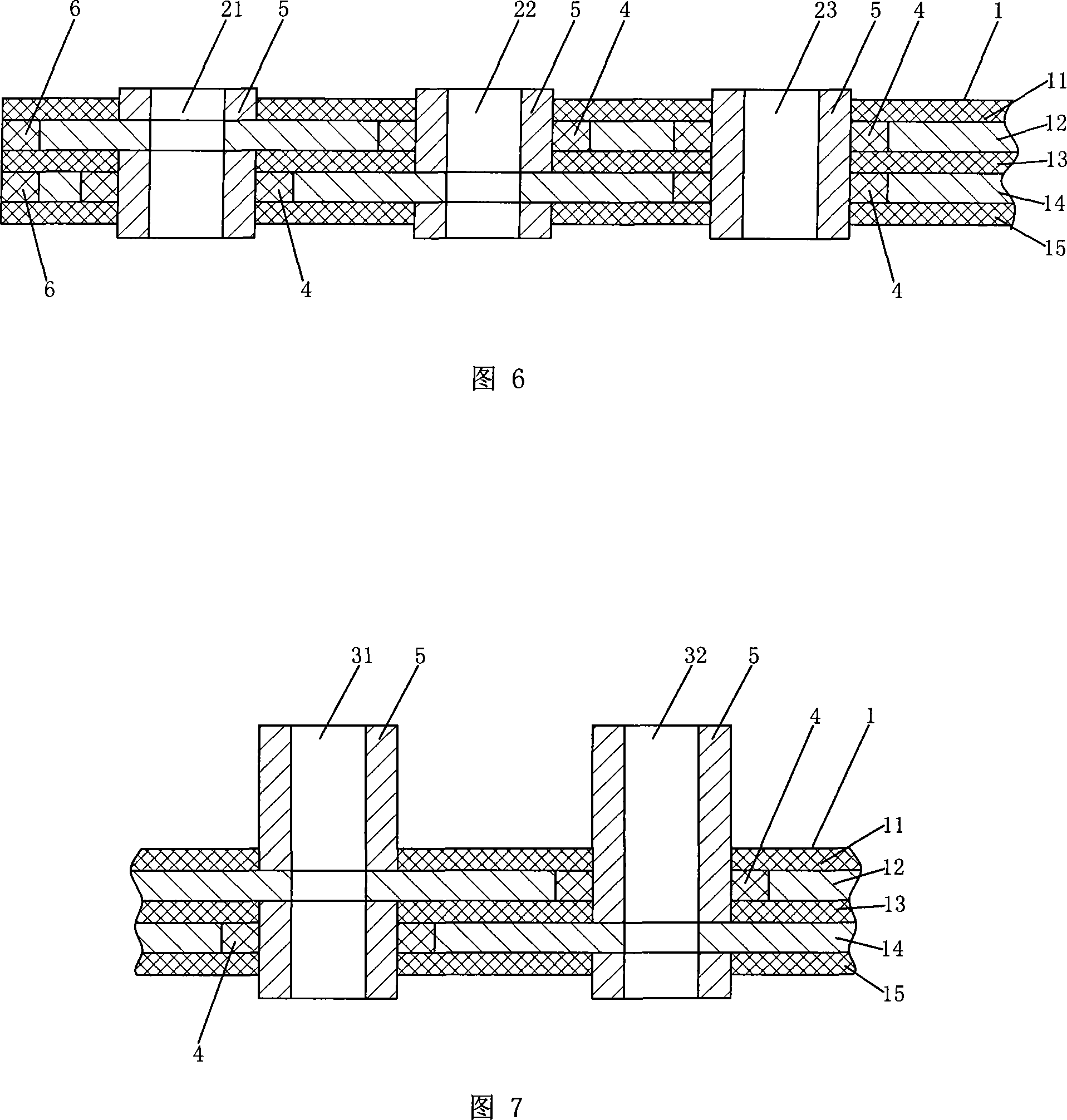

[0029] Figures 6 and 7 show that the structure of this example is basically the same as that of Example 1, the only difference is that the conductive ring 5 of this example is not a monolithic structure, but is composed of sections: the power is correct The conductive ring 5 on the polar hole 21 and the positive hole 31 is tightly connected by the upper and lower sections and the part where the positive plate 12 extends into the two sections to form a conductive ring 5 electrically connected to the positive plate 12; and the power The conductive ring 5 on the terminal negative polarity hole 22 and the negative hole 32 is closely connected by the upper and lower sections and the embedded part where the negative plate 14 extends between the two sections to form a conductive ring electrically connected to the negative plate 14 5. In the process of bonding and pressing each layer of material into a laminated busbar, the segmented conductive ring 5 can be conveniently assembled on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com