Apparatus and methods for treating components of packaging units, particularly bottles and/or caps

A technology of equipment and sterilizing device, which is applied in packaging sterilization, packaging, bottling machines, etc., can solve problems such as vibration, affecting sterilization efficiency, increasing instantaneous power peak value, etc., and achieves high productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

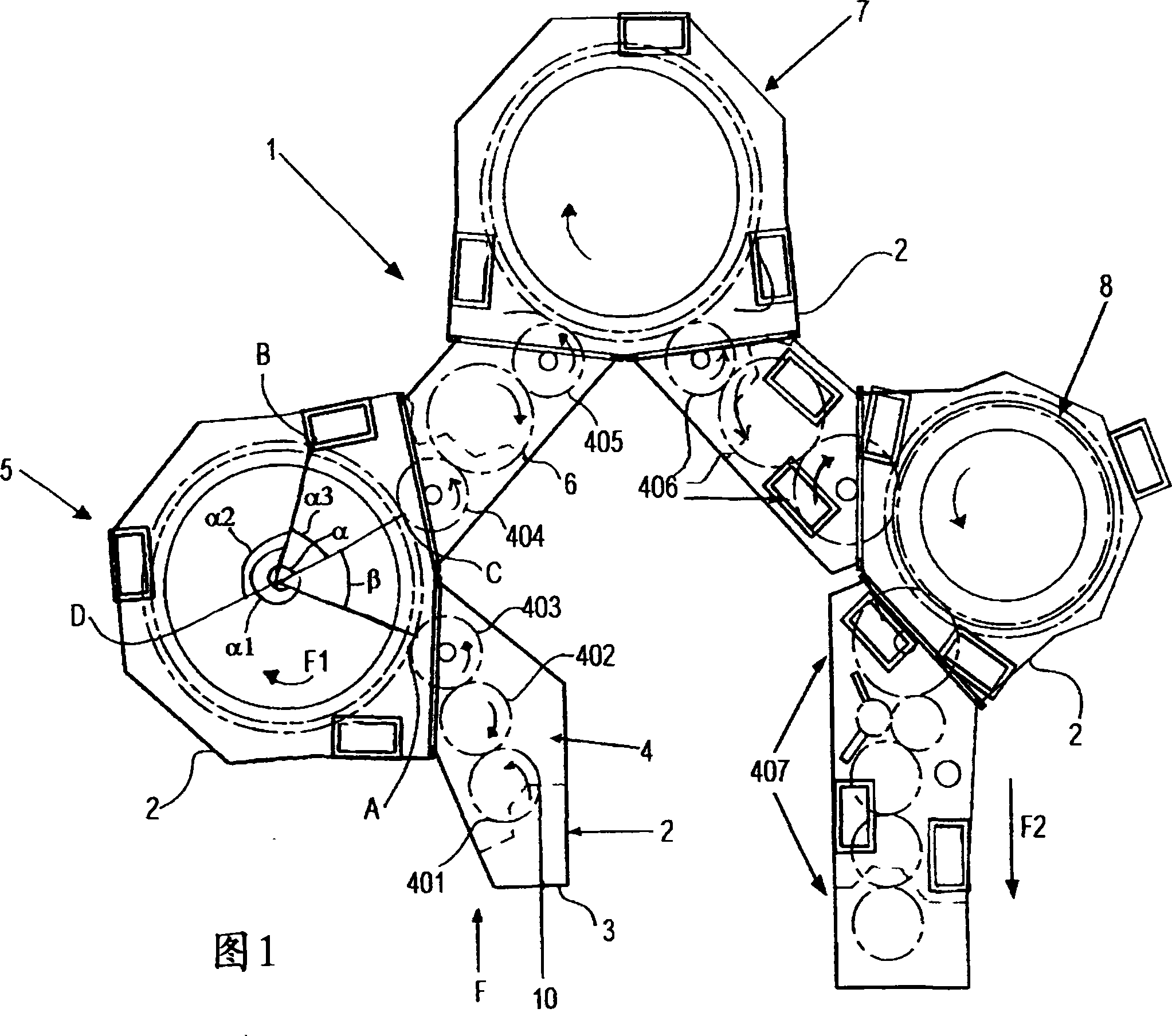

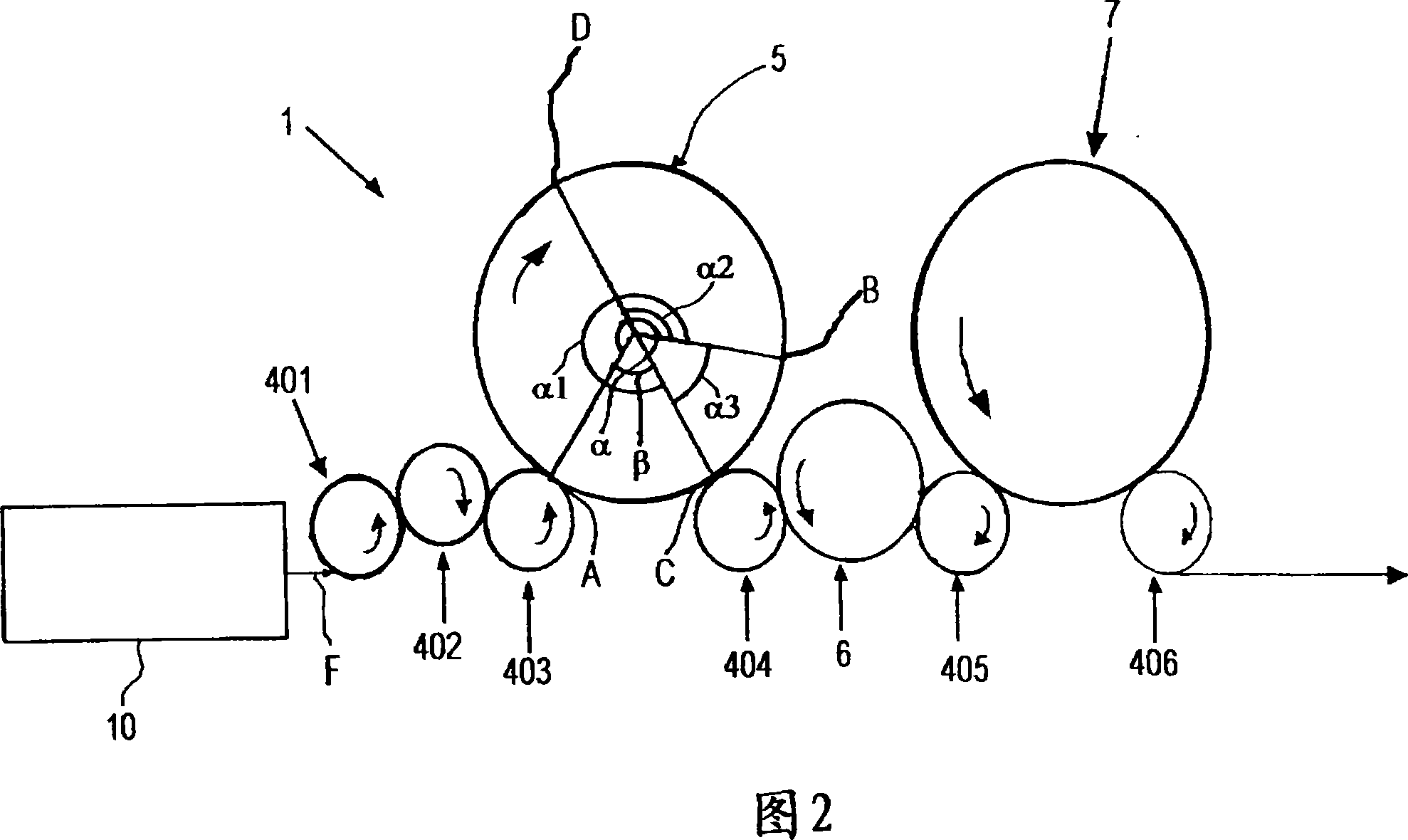

[0083] Referring to Figures 1 and 2, there is shown a system 1 for processing components of packaging units from a supply line 10, particularly components suitable for obtaining bottles and / or caps of filled sterile containers.

[0084] The device 1 is externally delimited by a wall 2 which has the function of isolating the device from the external environment, thus ensuring that the sterile state is maintained inside it. For this purpose, a slight overpressure is created inside the wall 2 relative to the outside environment, in order to prevent the entry of air and possible contaminants from the outside environment.

[0085] The bottles to be sterilized are introduced into the device 1 from the supply line 10 in the direction of the arrow F at the inlet zone 3 of the first sterilization zone 4 and are subjected to a series of treatments in the device 1 along their path, in particular ground, subjected to the action of a plurality of sterilization devices arranged along the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com