Small-sized self-walking hand mower

A walking lawn mower and self-propelled technology, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the needs of the rapid development of animal husbandry and grass industry, and the annual processing volume of grass products is less than 20 10,000 tons, unable to adapt to the needs of forage harvesting operations, etc., to achieve the effect of promoting sustained and rapid development, increasing forage production, and stable and reliable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

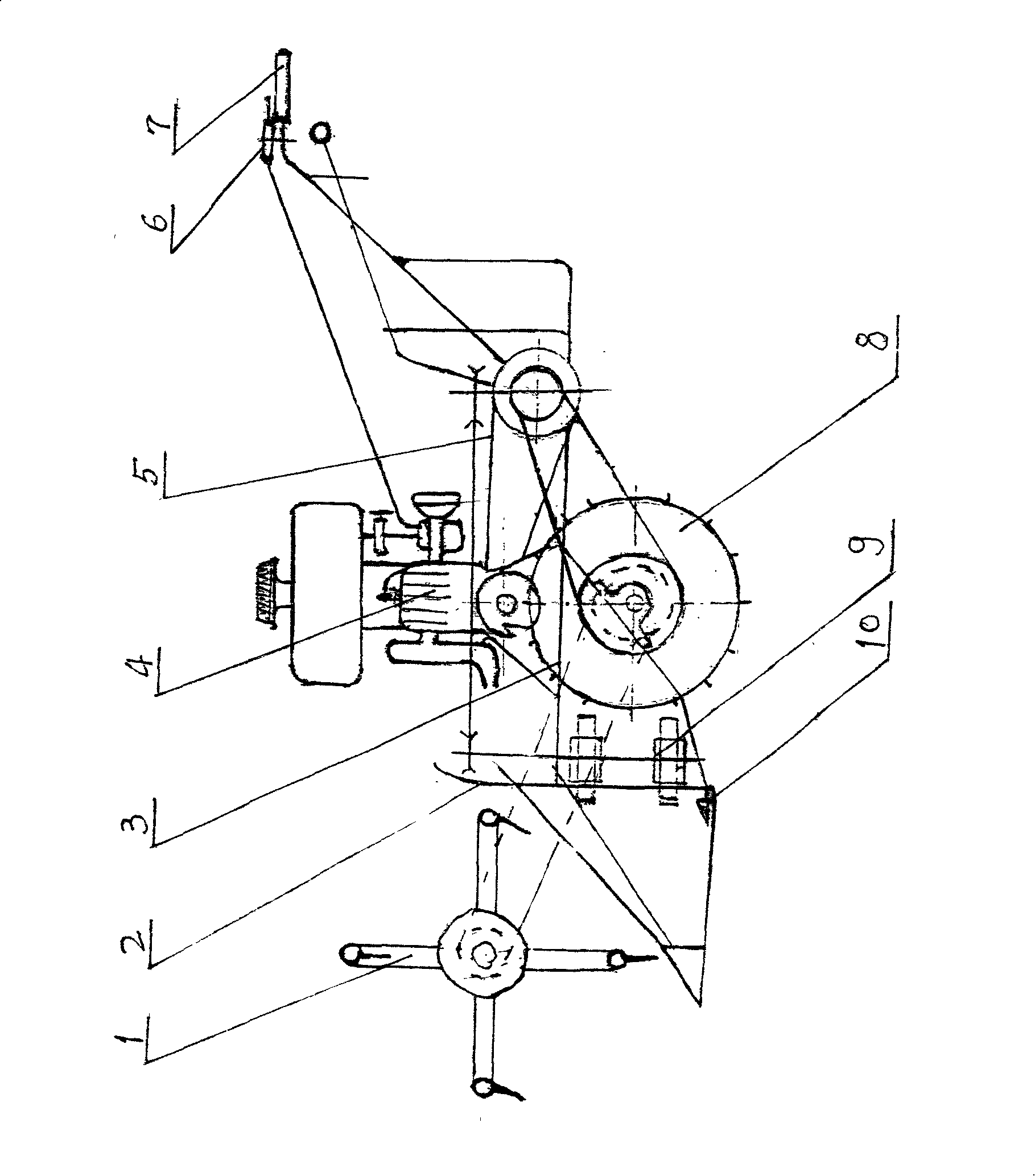

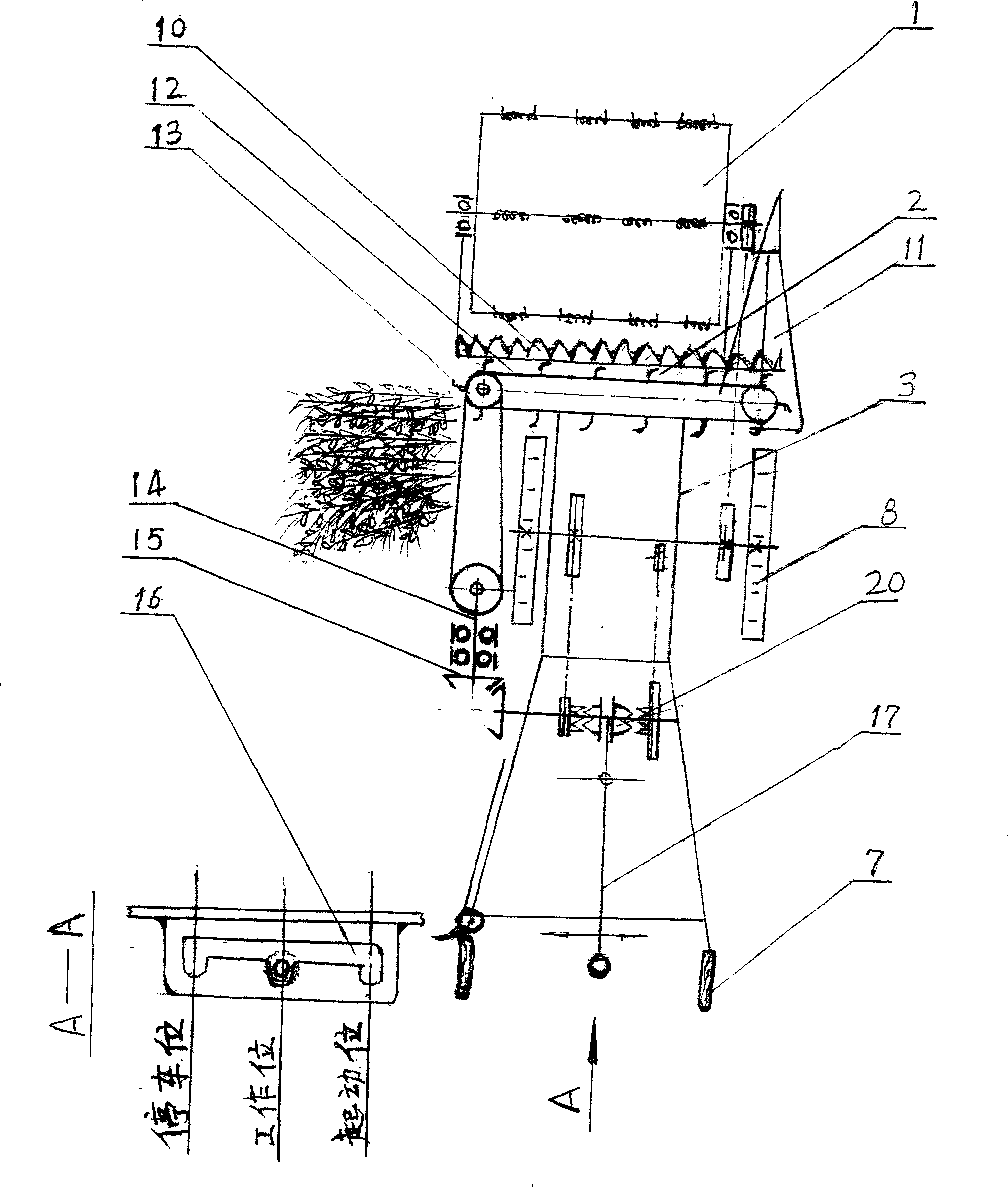

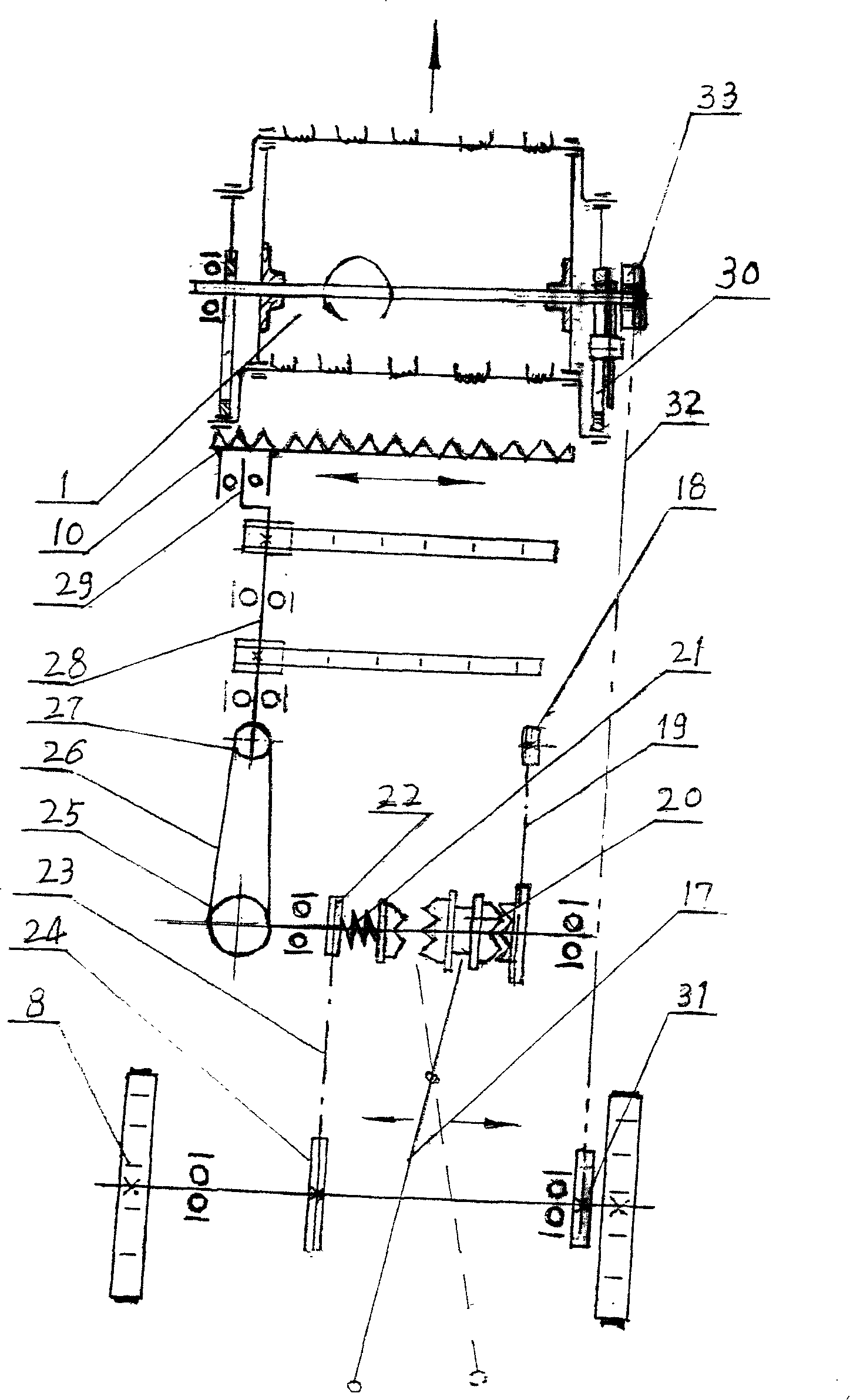

[0015] exist figure 1 In the shown embodiment, the reel (1) is installed on the front top of the vertical harvesting platform (2), and the vertical harvesting platform (2) is vertically installed on the front end of the frame (3), and the gasoline engine (4) is installed on the machine. The upper plane of the frame (3) is respectively connected with the ground wheel (8), the conveying mechanism (9), the cutter (10) and the reel (1) through the transmission mechanism (5), and the rotating speed of the gasoline engine (4) passes through The hand throttle (6) and the throttle cable are used to control the mower. The working state of the lawn mower is controlled by the hand control mechanism (7) and the clutch handle. The ground wheel (8) is welded by a circular steel ring with uniformly distributed The spokes are welded to the hub, and the outer circular surface is evenly welded axially with small anti-skid teeth with a height of 8mm and a length of 50mm. Two ground wheels (8) ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com