Digital control helical turning-milling machine

A technology of helical and milling machines, applied in the direction of milling machine equipment, milling machine equipment details, large fixed members, etc., can solve problems such as not being able to meet user needs, and achieve the effect of expanding the scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] (See the accompanying drawings in the manual)

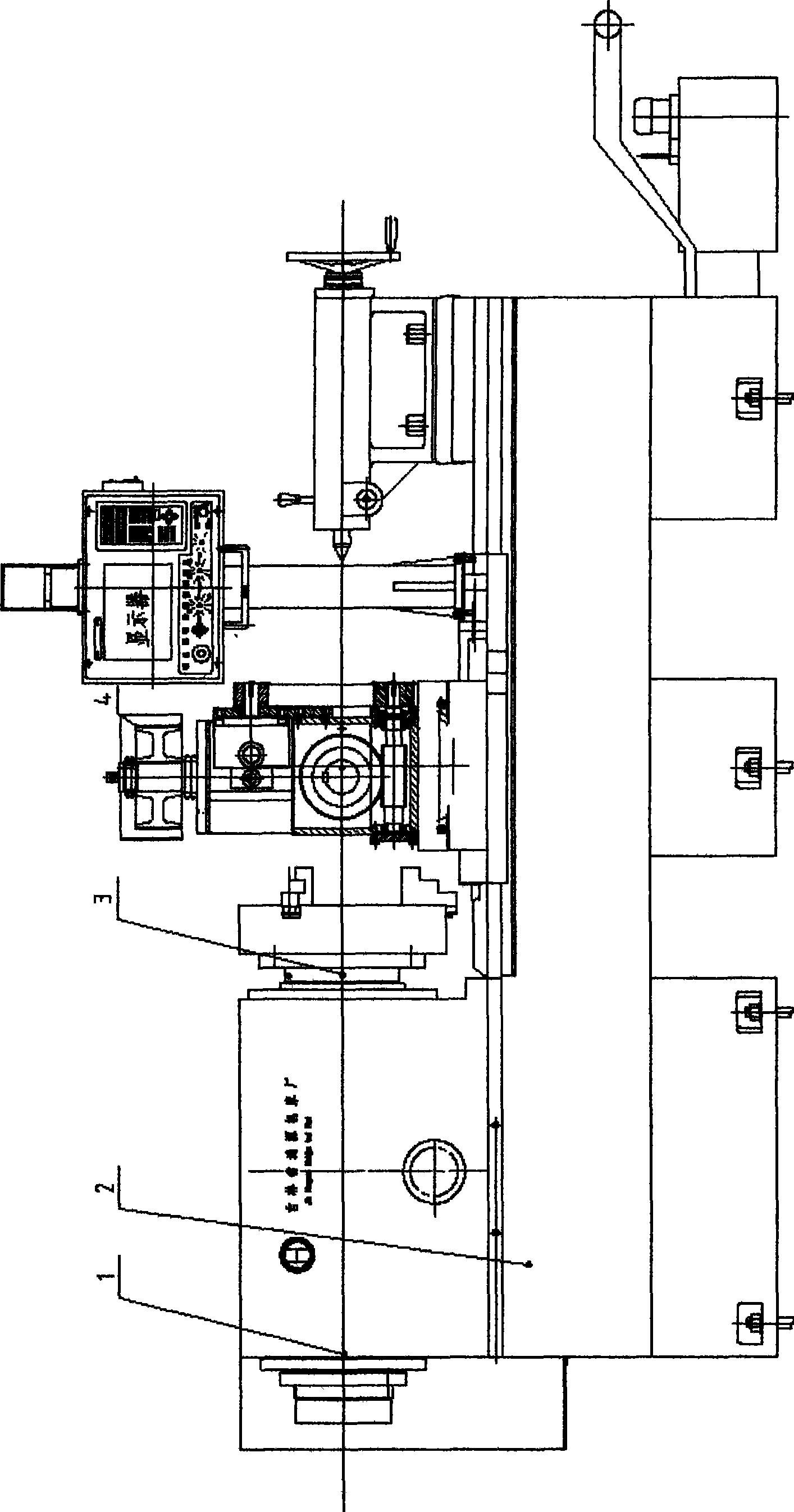

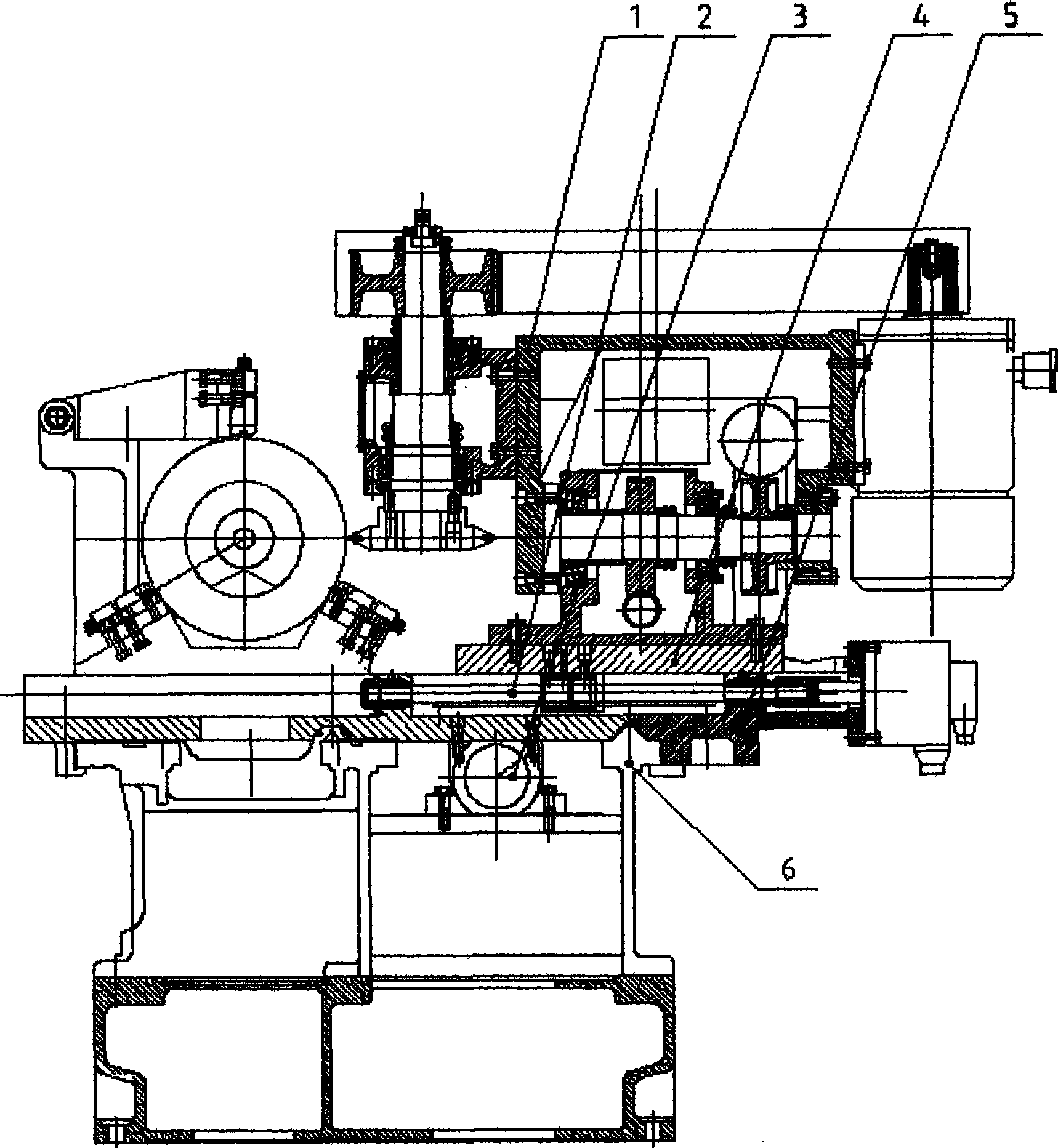

[0017] Numerically controlled spiral turning and milling machine of the present invention is roughly the same as common lathe mechanical structure, and it comprises: lathe bed (such as figure 1 Shown in 2), headstock (1), spindle (3) (inner hole dφ200mm-φ300mm), rotary milling head (4), feed mechanism (such as figure 2 Shown in 5, 6), this lathe is characterized in that:

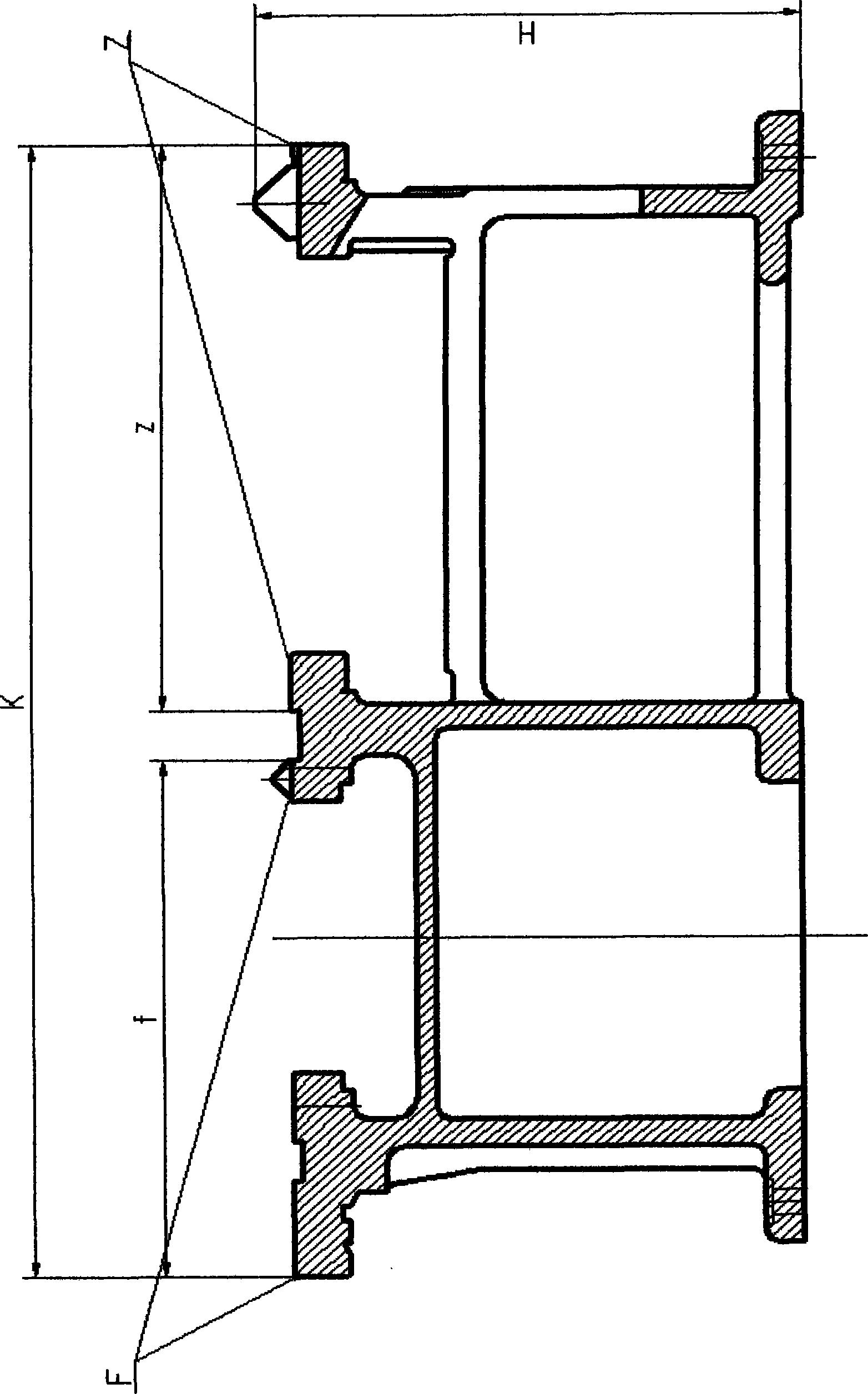

[0018] In the workpiece spindle device (such as Figure 4 In the shown 4), a servo motor drives the worm (8) through the gear, and the worm gear (7) drives the workpiece spindle to rotate (4) through the clutch (6) to complete the milling process. In addition, in the workpiece spindle device, a variable frequency motor drives the workpiece spindle (4) to rotate through the synchronous belt (3) and the gear (5). The clutch (6) is disengaged from the worm wheel (7), and the workpiece main shaft (4) rotates the worm wheel (7) without rotating to complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com