Molybdenum-free low-cost hot working die steel

A hot work die steel, low-cost technology, applied in the field of tooling and die, can solve the problems of rising smelting cost, and achieve the effects of good tempering resistance stability, low cost and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

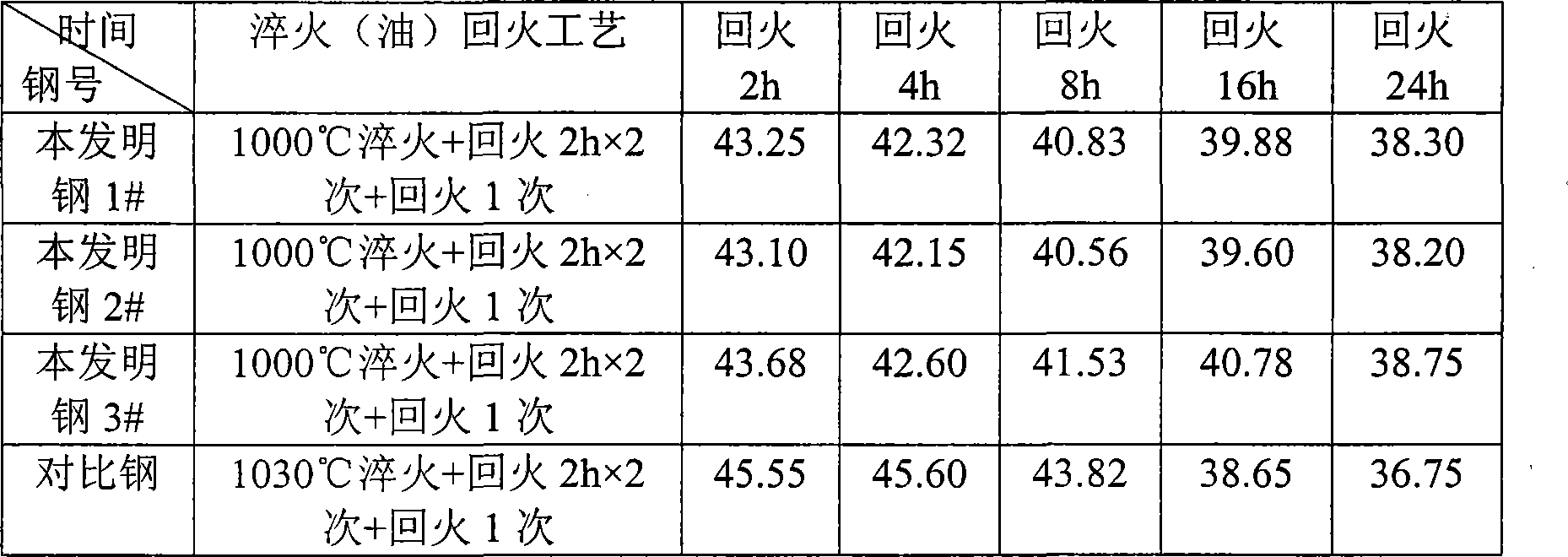

[0018] According to the chemical composition range designed above, 3 furnaces of the steel of the present invention and 1 furnace of comparative steel (H13) were smelted on a 25kg vacuum induction furnace, and their specific chemical compositions are shown in Table 1. Molten steel is cast into ingots and forged into φ16mm, □15mm rods. After the example steel and the comparison steel were annealed, they were processed into samples, which were quenched and tempered (quenched at 1050°C and tempered at 510-650°C). The mechanical properties at room temperature are shown in Tables 2-7.

[0019] The steel of the invention has comprehensive mechanical properties equivalent to those of the contrast steel, and has higher impact toughness than the contrast steel. After quenching and tempering at 510-650°C, the hardness, strength and tempering resistance stability of the steel of the present invention are equivalent to those of the comparison steel.

[0020] 1. After quenching (the quenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com