Warm-air heating machine

A heating machine and fan heater technology, which is applied in the directions of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of noise of furnace air supply device, economical reduction, insufficient heat of solid fuel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

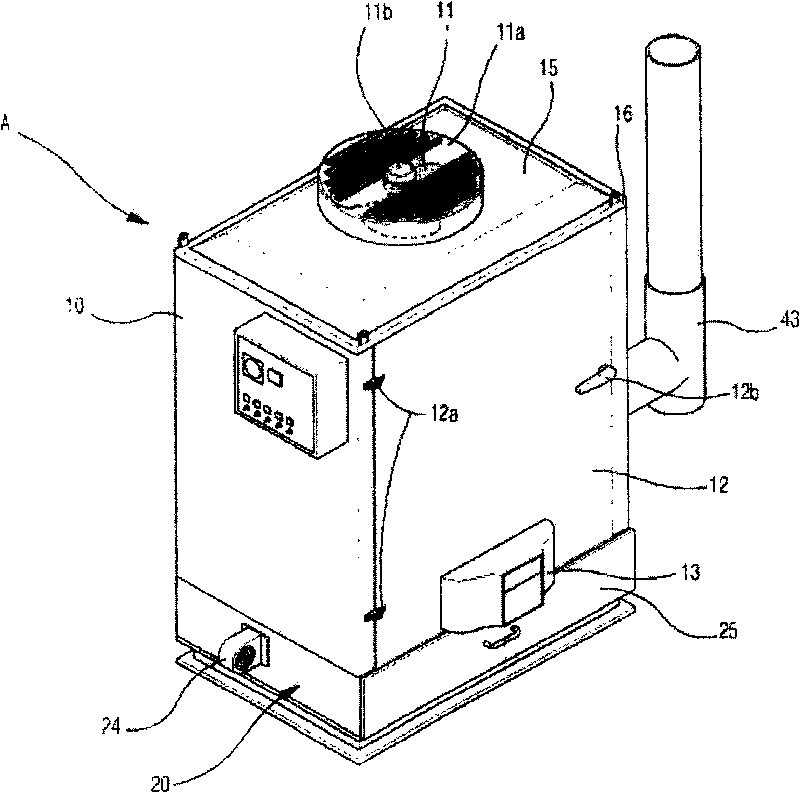

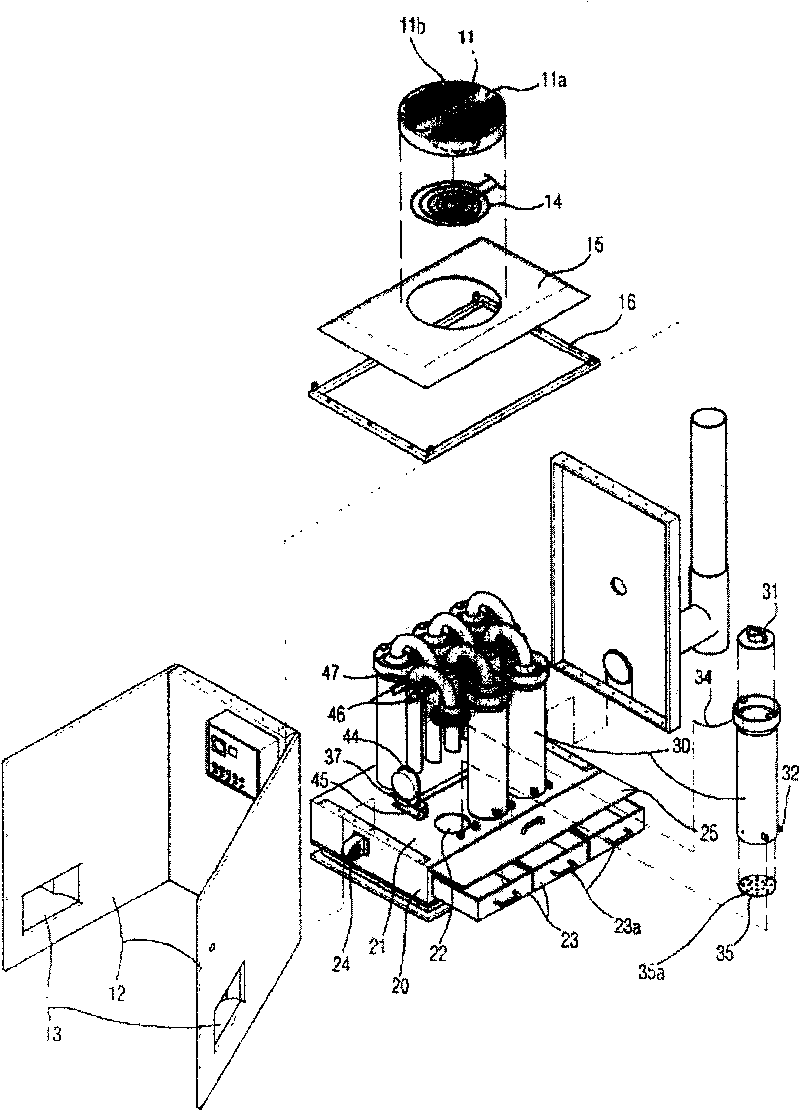

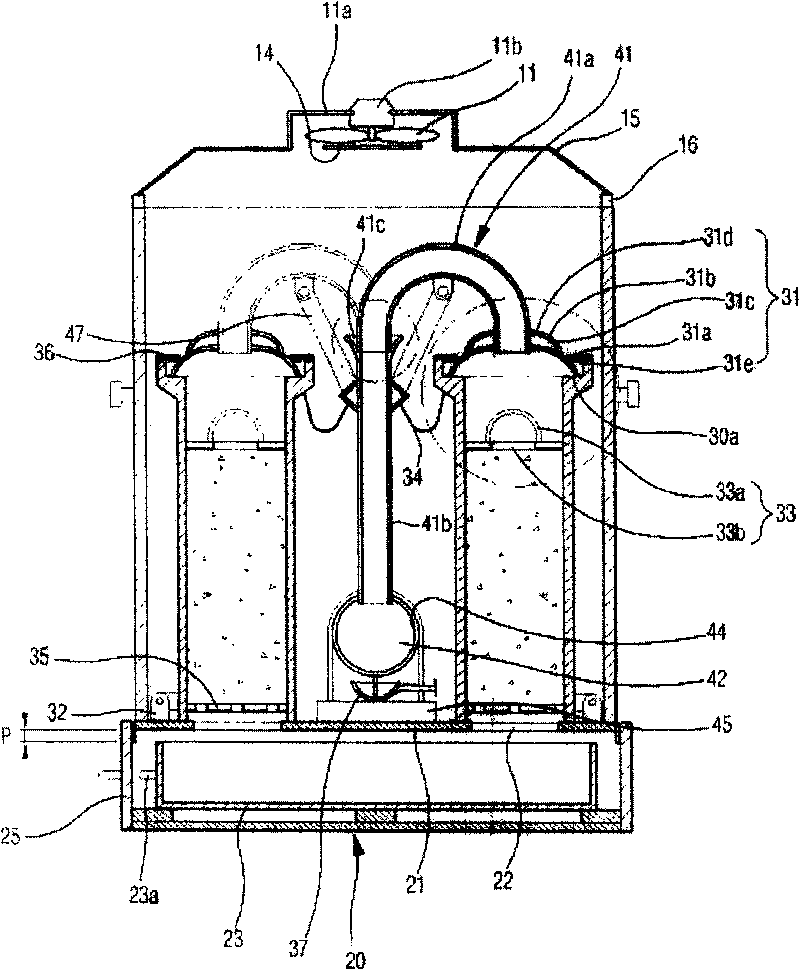

[0033] Referring to the accompanying drawings, the warm air heater of the present invention having the above characteristics will be described in detail.

[0034] In the warm air heater of the present invention, a fan 11 that blows air into the cylindrical body 10 is provided above the heater body A, that is, the cylindrical body 10, and a fan 11 that blows air into the cylindrical body 10 is provided on both sides of the cylindrical body 10 where the fan 11 is provided. The hinge 12a is a door 12 that can be opened and closed. A warm air outlet 13 for discharging warm air is formed on the door 12. A delivery pipe (not shown) is connected to the front end of the warm air outlet 13 . The above-mentioned fan 11 and the motor 11b are connected on the grid-shaped casing 11a.

[0035] In addition, a fan fixing plate 15 is also arranged above the body 10 provided with the fan 11 to provide safe and strong support for the fan 11, between the fan fixing plate 15 and the upper end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com