Carbon dioxide heat pump control method based on pressure-temperature

A carbon dioxide and control method technology, applied in heat pumps, refrigerators, refrigeration components, etc., can solve the problems of complex, no carbon dioxide heat pump systems, work performance coefficients, specific control methods, large throttling losses, etc., and achieve a good COP value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

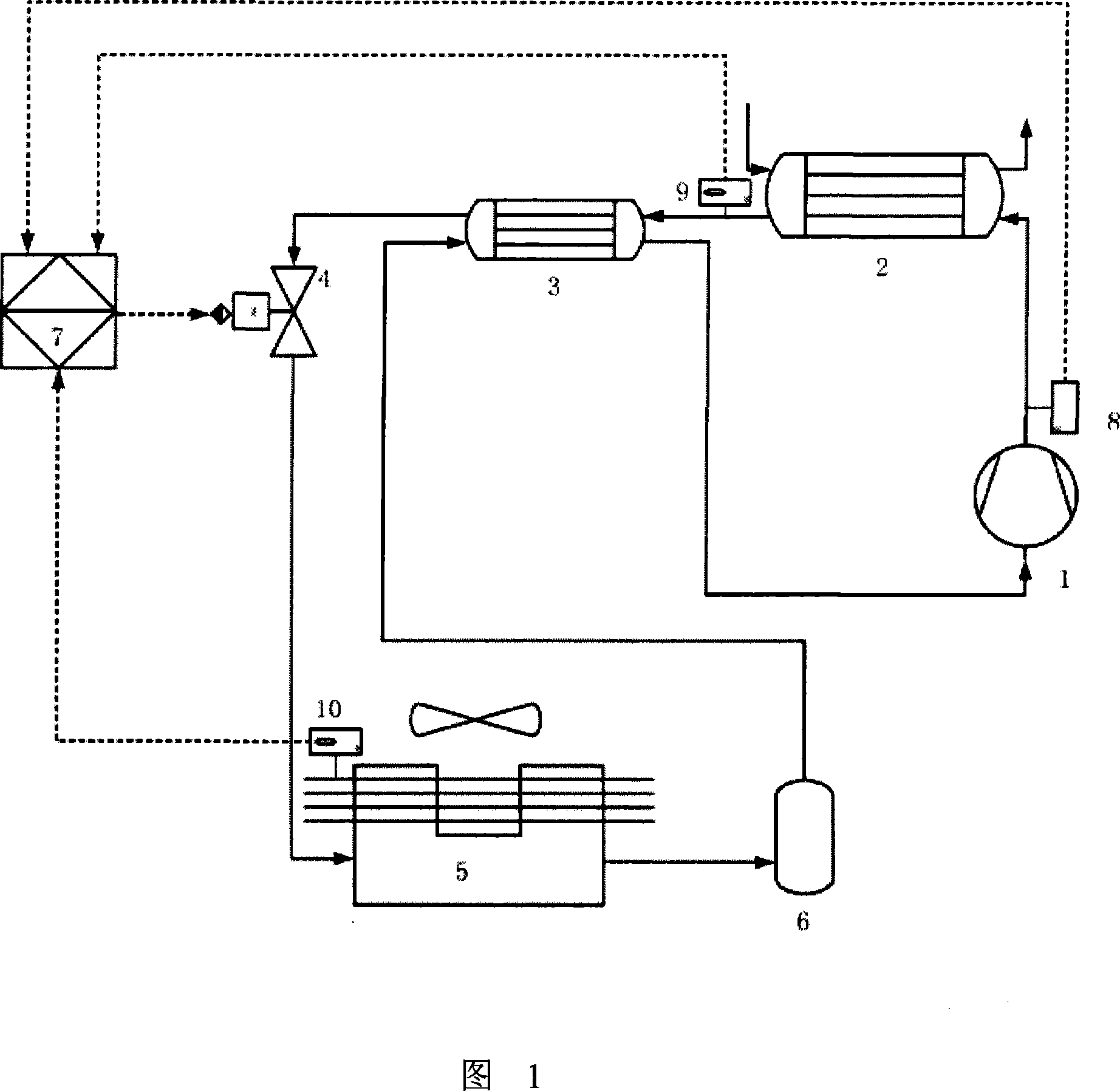

[0016] Referring to Fig. 1, the flow chart of the carbon dioxide heat pump system of the present invention is as follows: after the carbon dioxide gas enters the compressor 1 and is compressed, the high-temperature and high-pressure carbon dioxide gas enters the gas cooler 2 for cooling, and the released heat is used for heating hot water, and the supercritical carbon dioxide gas after cooling The gas enters the intermediate heat exchanger 3 for further cooling, and then passes through the throttling of the electronic expansion valve 4, enters the evaporator 5 for evaporation and heat exchange, and the low-temperature and low-pressure carbon dioxide refrigerant passes through the gas-liquid separator 6 to separate the low-temperature and low-pressure carbon dioxide refrigerant The agent gas enters the intermediate heat exchanger 3, further cools the supercritical carbon dioxide gas coming out of the gas cooler, and returns to the compressor 1 to complete a cycle. Due to control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com