Large-sized optical flat interferometry device and method

An optical plane, interferometric measurement technology, applied in the field of optical testing, can solve the problems of increasing production cost, affecting measurement accuracy, low lateral resolution, etc., achieving the effect of simple structure, reducing cost, and improving lateral resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

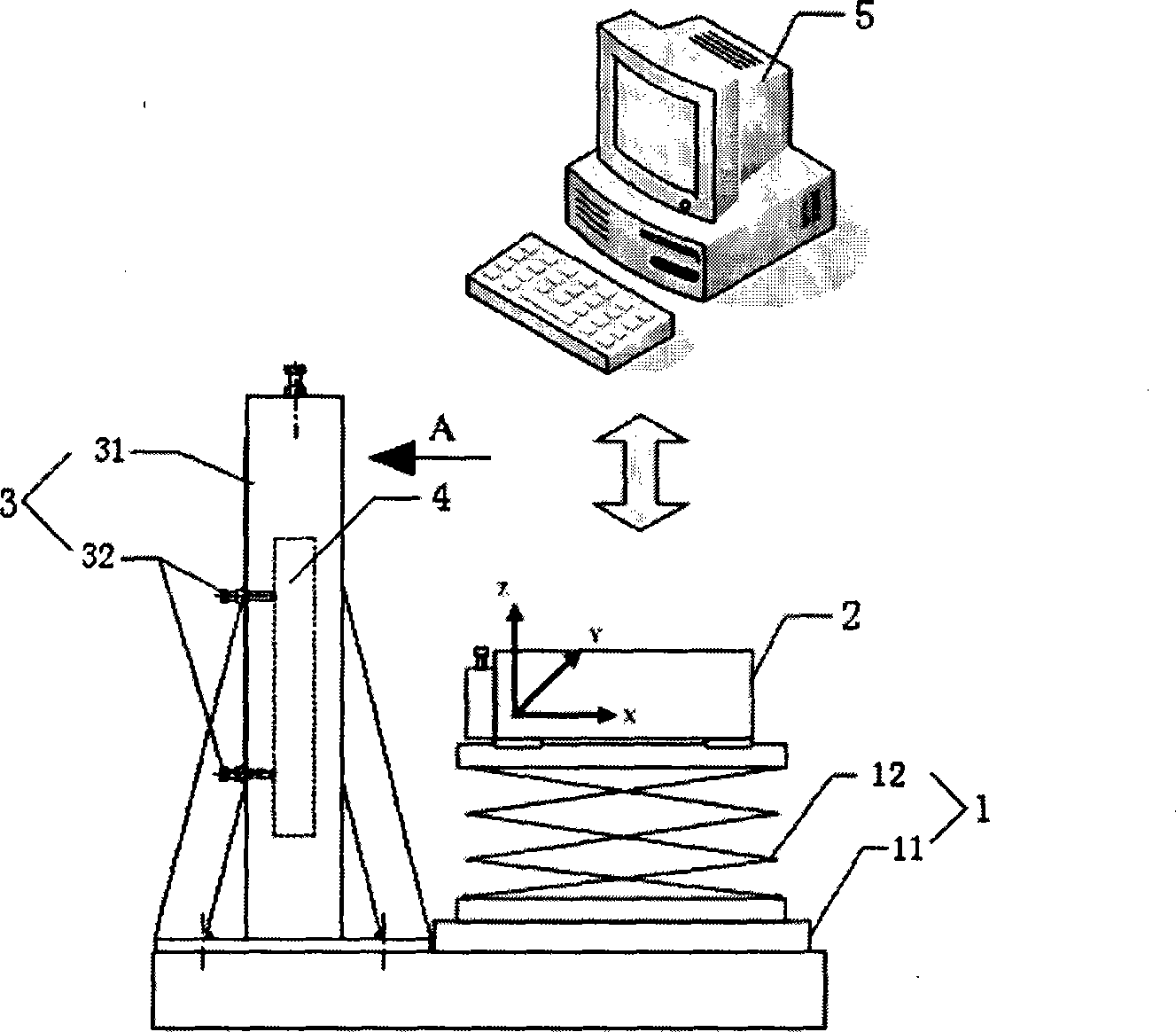

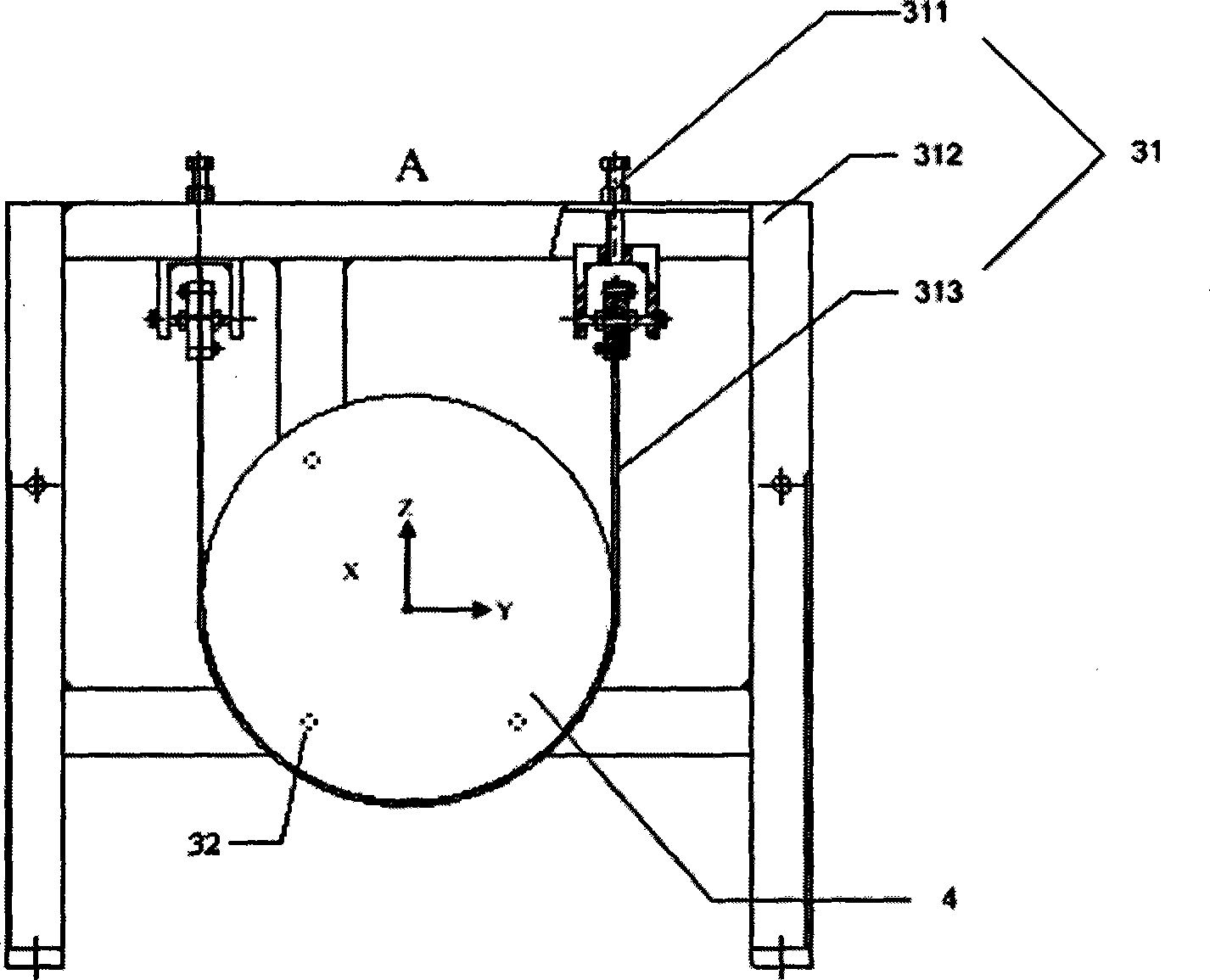

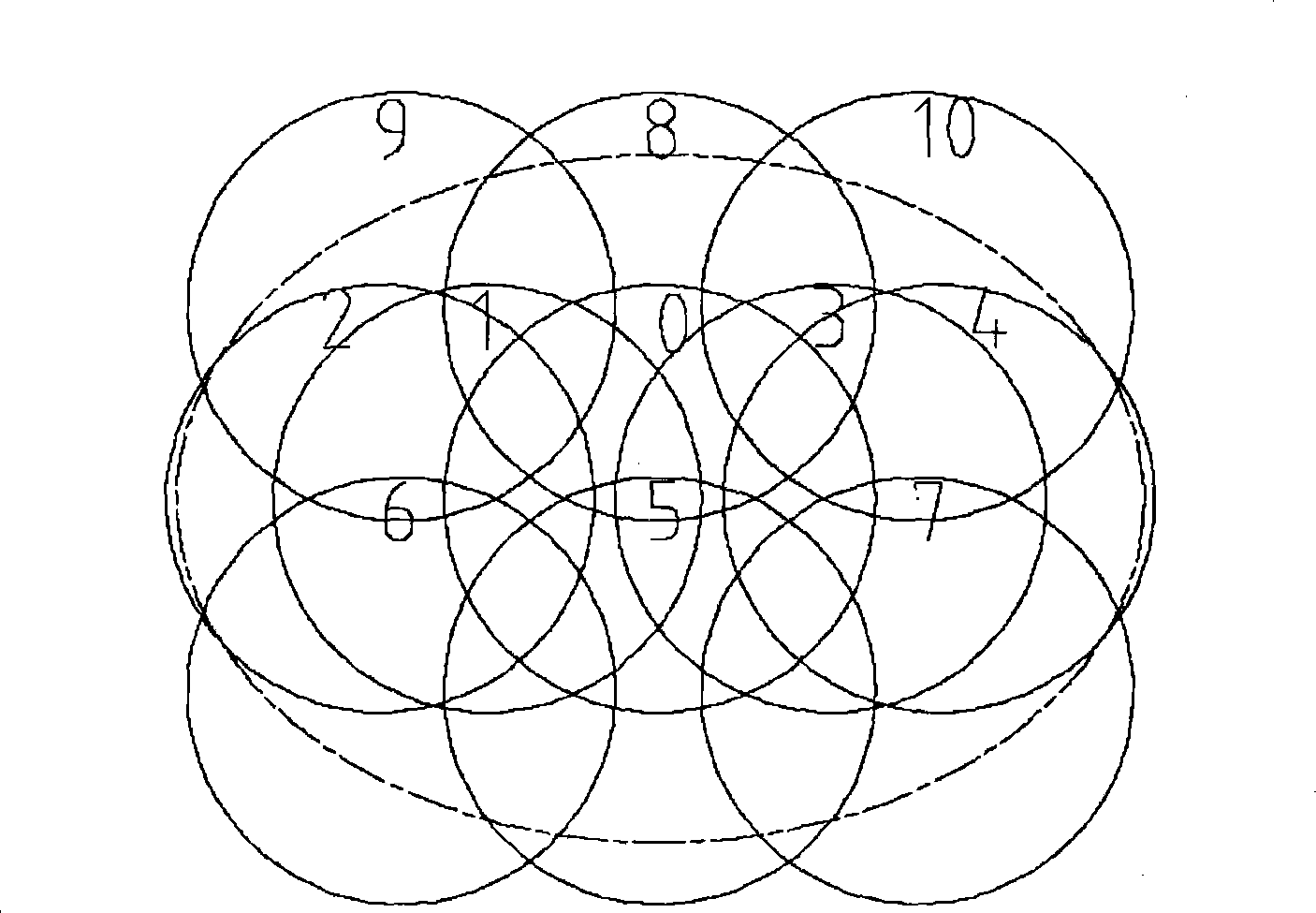

[0031] Such as figure 1 As shown, the large-scale optical plane interferometric measurement device of the present invention has an interferometer two-axis linear motion adjustment platform 1, and is located in front of the adjustment platform 1 and is provided with a two-dimensional tilt adjustment platform 3 for the plane mirror to be measured. The adjustment platform 1 is equipped with a laser wavefront interference The instrument 2 is connected with the laser wave surface interferometer 2 and has a main control computer 5 with a built-in measurement data processing algorithm program, and the measured plane mirror 4 is installed on the adjustment platform 3 during measurement.

[0032] The interferometer two-axis linear motion adjustment platform 1 includes a horizontal Y-axis motion assembly 11 and a vertical Z-axis motion assembly 12 superimposed on the Y-axis assembly. The Y-axis assembly 11 is composed of an AC servo motor and its encoder, and an elastic coupling. The Z-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com