Fluid control apparatus

A technology of a fluid control device and a fluid control valve, which is applied in the direction of fluid pressure control, valve device, and flow control of an electrical device, and can solve problems such as errors, complexity, and damage to the driver control valve 308

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

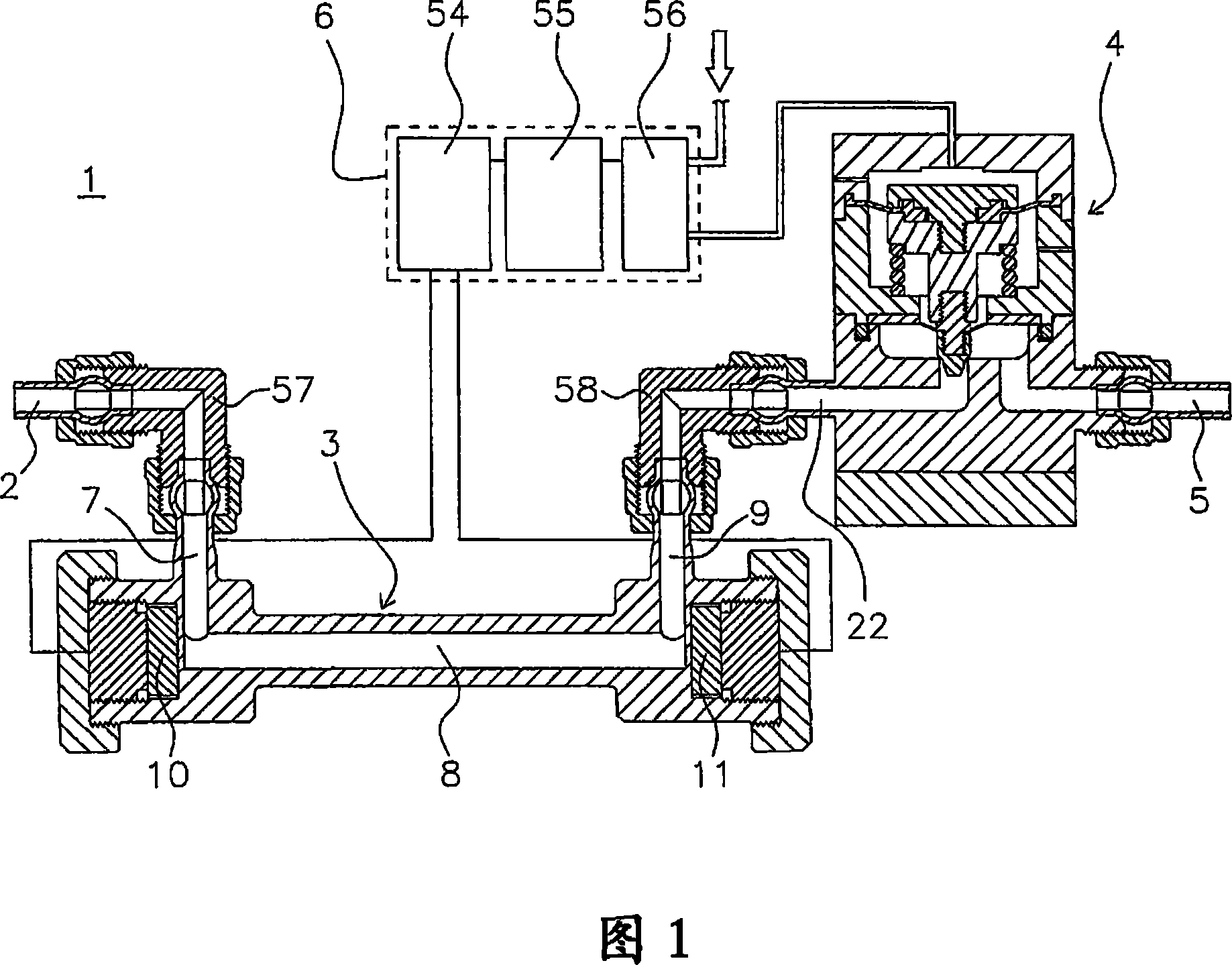

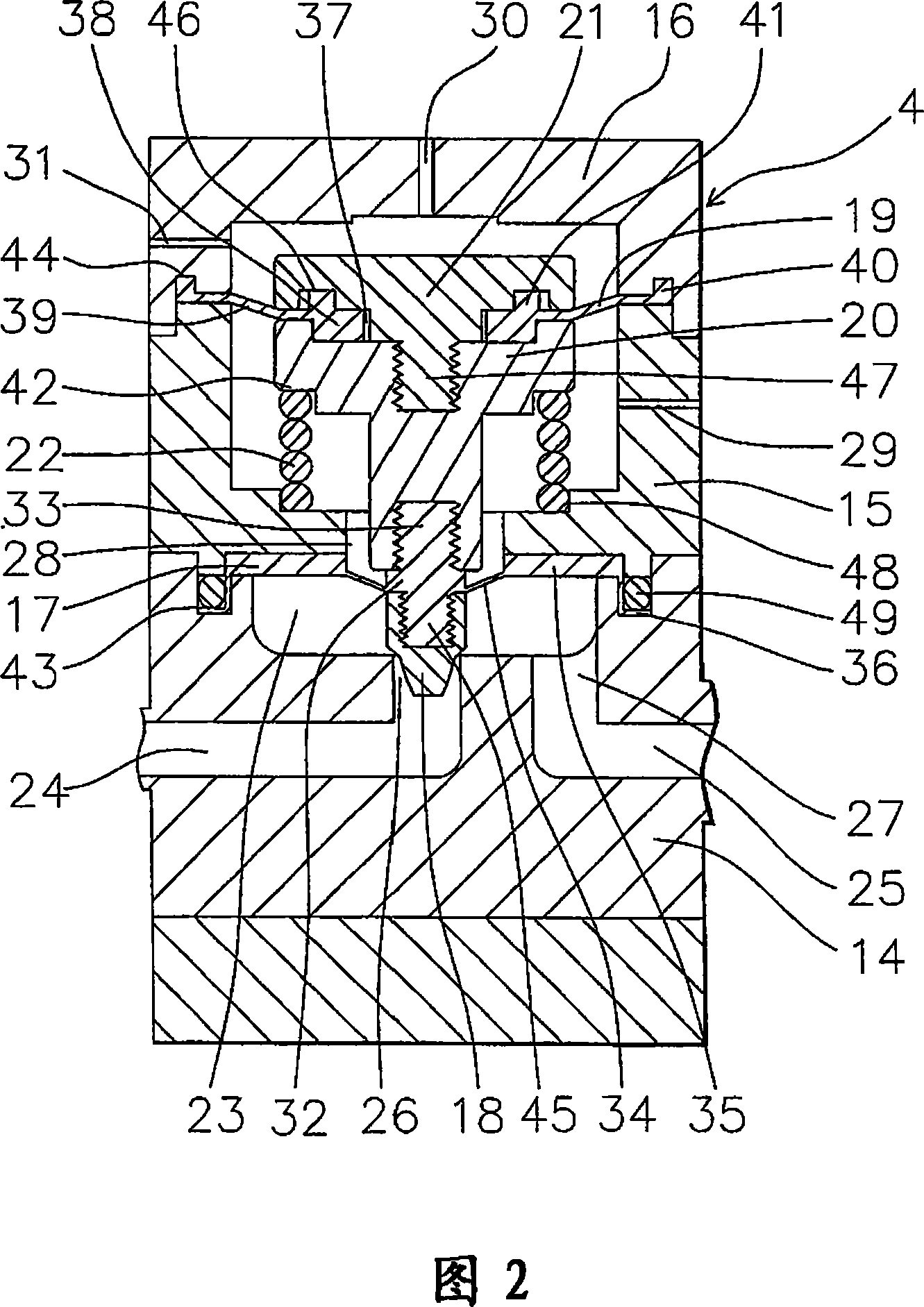

[0076] Hereinafter, a fluid control device according to a first embodiment of the present invention will be described based on FIGS. 1 and 2 .

[0077] Reference numeral 1 denotes a fluid control device installed in a semiconductor manufacturing device that performs an etching process in semiconductor manufacturing. The fluid control device 1 is formed of a fluid inlet 2, a flow meter 3, a fluid control valve 4, a fluid outlet 5, and a control unit 6, and their respective structures are as follows.

[0078] 2 is a fluid inlet made of PFA. The fluid inflow port 2 communicates with an inlet channel 7 of a flow meter 3 described later.

[0079] 3 is a flow meter for measuring the flow rate of a fluid. The flow measuring device 3 has: an inlet flow path 7, a straight flow path 8 vertically arranged from the inlet flow path 7, and an outlet flow path 9 vertically arranged from the straight flow path 8 and parallel to the inlet flow path in the same direction, Ultrasonic vibrator...

Embodiment 2

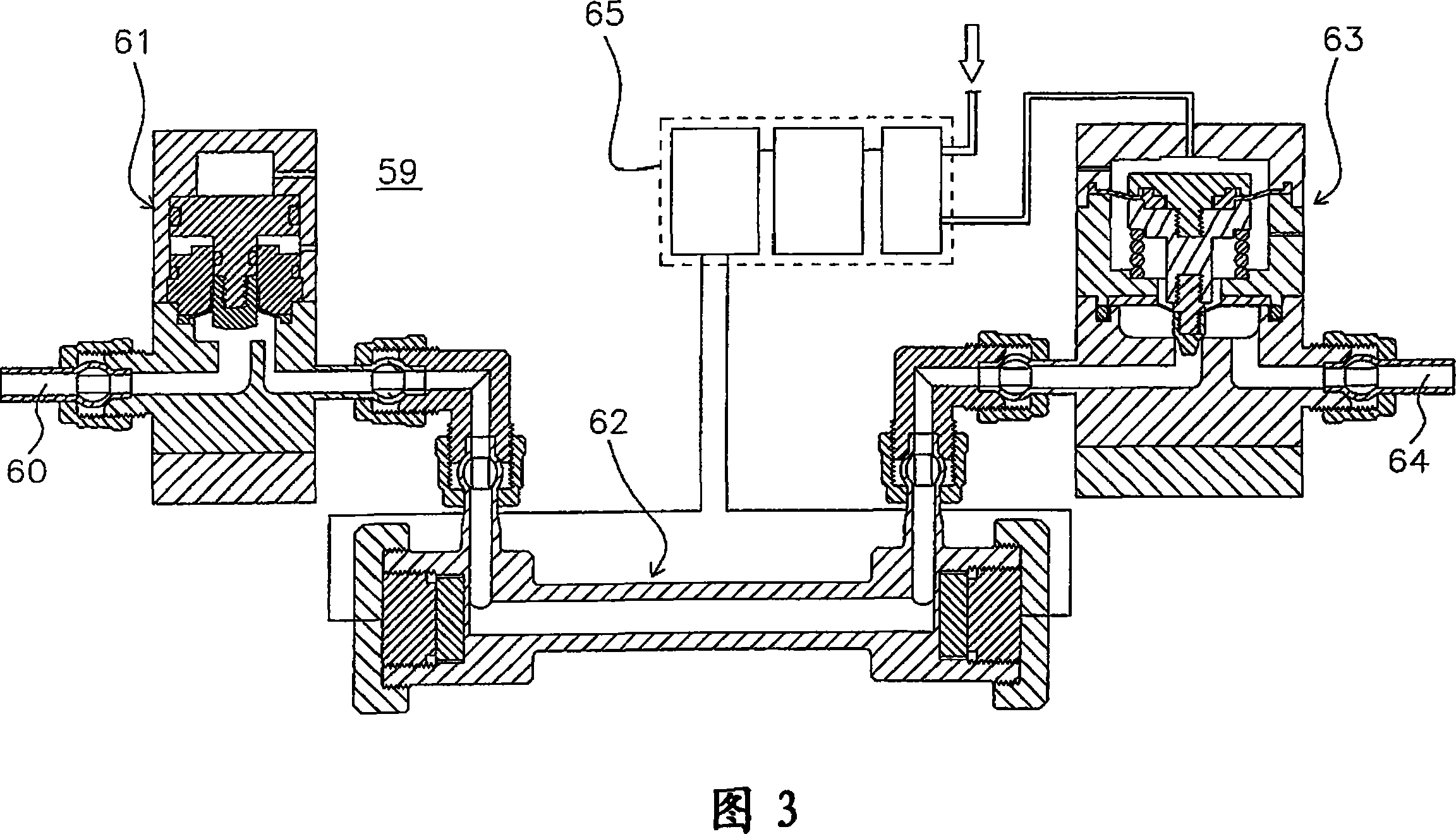

[0103] Next, a fluid control device which is a second embodiment of the present invention will be described based on FIGS. 3 and 4 .

[0104] As shown in FIG. 3, the fluid control device 59 is composed of a fluid inlet 60, an on-off valve 61, a flow meter 62, a fluid control valve 63, a fluid outlet 64, and a control unit 65. The respective structures are as follows .

[0105] As shown in FIG. 4 , the on-off valve 61 is formed of a main body 66 , a drive portion 67 , a piston 68 , a diaphragm retainer 69 , and a valve body 70 .

[0106] 66 is a main body made of PTEF, with a valve chamber 71 in the center of the upper end in the axial direction, an inlet flow path 72 and an outlet flow path 73 communicating with the valve chamber 71, the inlet flow path 72 communicates with the fluid inlet 60, and the outlet flow path 73 communicates with the fluid inlet The flow meter 62 communicates. In addition, an annular groove 74 is provided on the upper surface of the main body 66 out...

Embodiment 3

[0117] Next, a fluid control device according to a third embodiment of the present invention will be described based on FIGS. 5 and 6 .

[0118] As shown in FIG. 5, the fluid control device 81 is composed of a fluid inlet 82, a pressure regulating valve 83, a flow meter 84, a fluid control valve 85, a fluid outlet 86, and a control unit 87. The respective structures are as follows. .

[0119] As shown in FIG. 6 , 83 is a pressure regulating valve for attenuating pressure fluctuation of fluid.

[0120] The pressure regulating valve 83 is formed of a main body 12w, a valve cover 13w, a spring seat 14w, a piston 15w, a spring 16w, a first valve mechanism body 17w, a second valve mechanism body 18w, and a base member 19w.

[0121] 12w is a main body made of PTFE, which has a second void 20w opened from the center of the lower part to the bottom, and a first void 21w opened to the upper surface from the upper part and has a larger diameter than the second void 20w. An inlet chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com