Degumming device

A degumming device and machine body technology, which is applied in the field of mechanical processing, can solve the problems of reduced magnetic performance of permanent magnets, long boiling time, and reduced magnetic energy level of permanent magnets, so as to avoid internal corrosion, shorten processing time, and shorten processing time. Effect

Inactive Publication Date: 2010-11-10

SHENYANG POLYTECHNIC UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

(1) It takes a long time to cook in water and wastes a lot of energy

(2) After boiling, the surface of the permanent magnet is seriously corroded

(3) Boil in water for a long time at high temperature to reduce the magnetic energy level of the permanent magnet (the magnetic performance of the permanent magnet is reduced, and the grade of the permanent magnet product is reduced)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

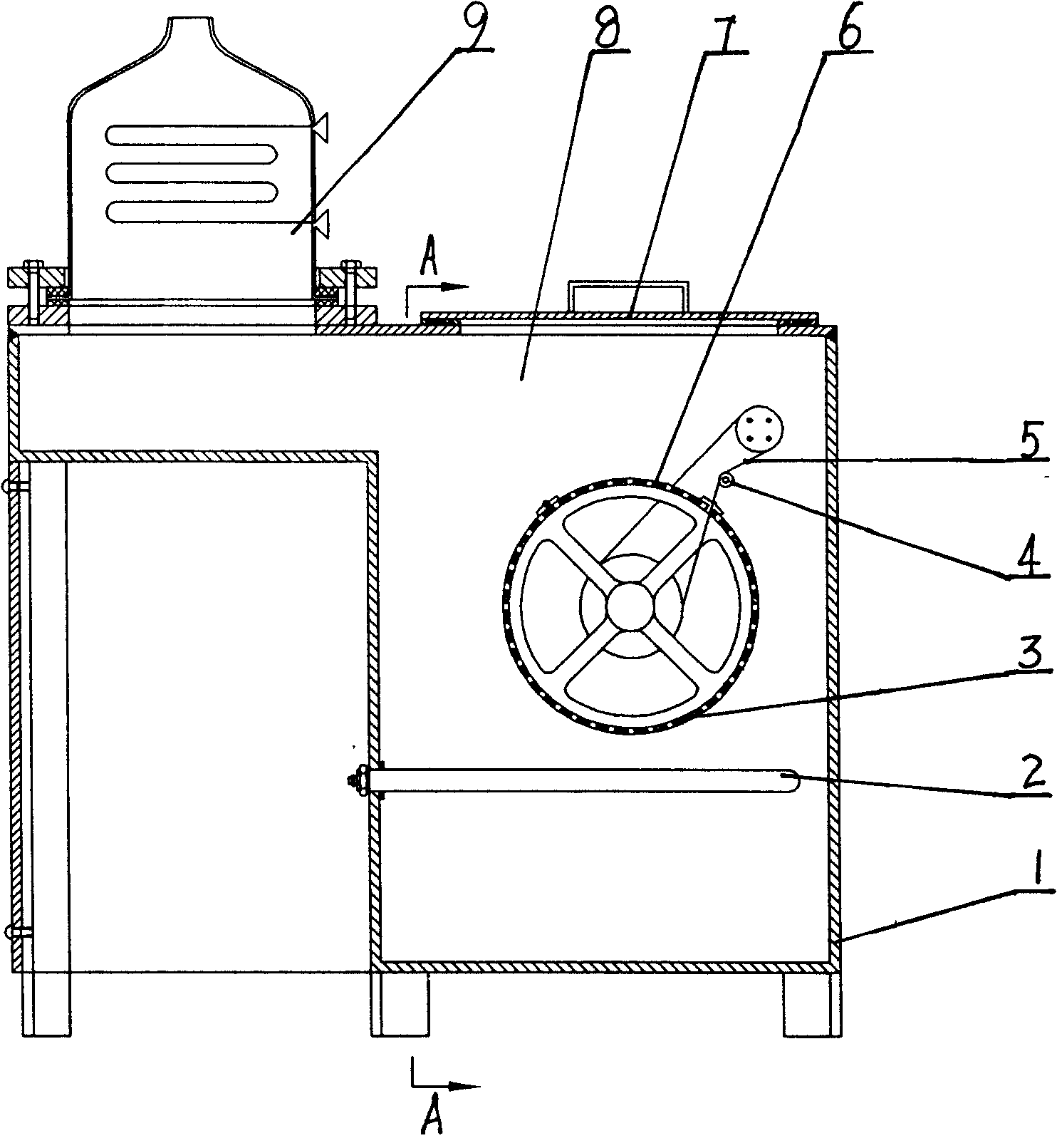

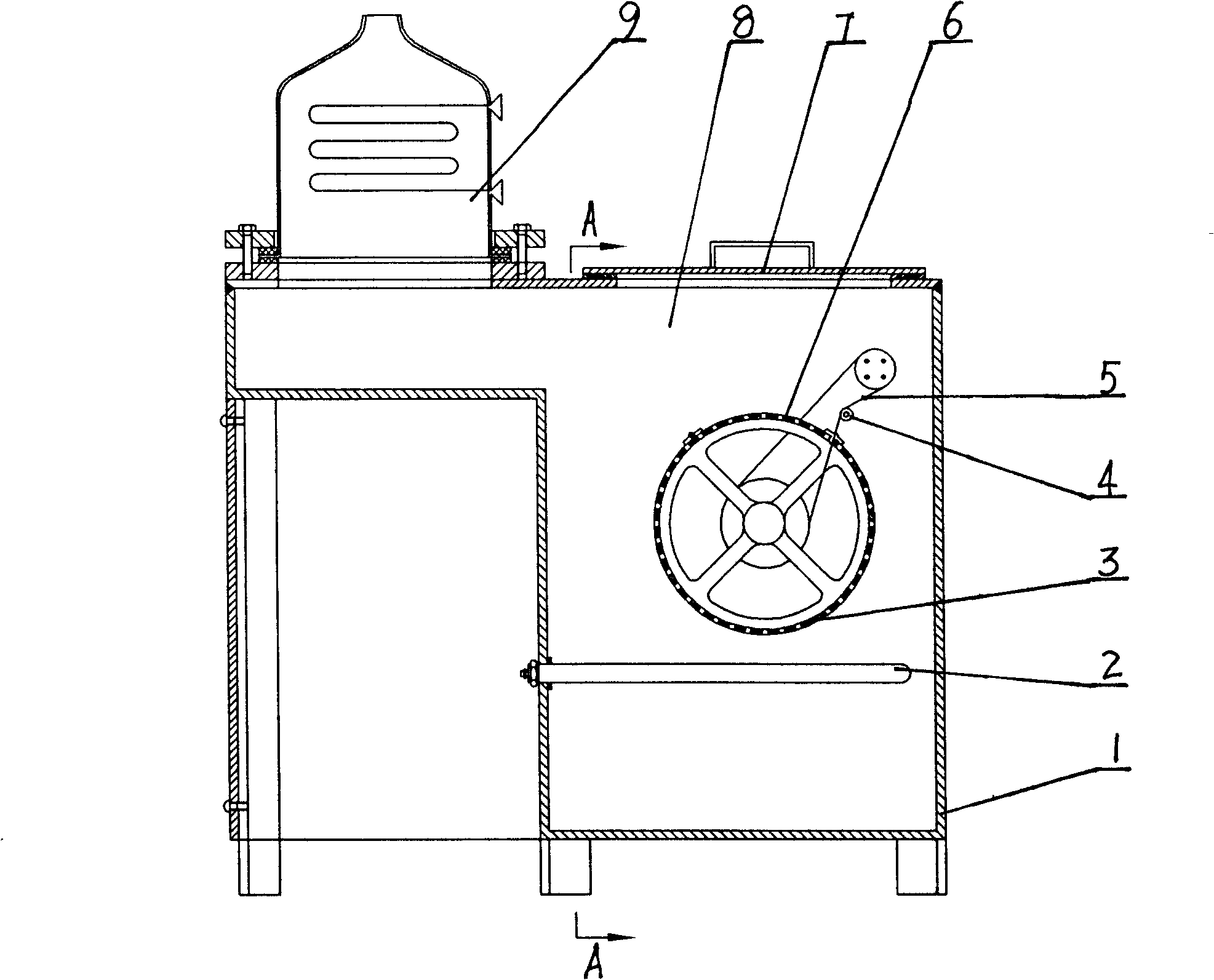

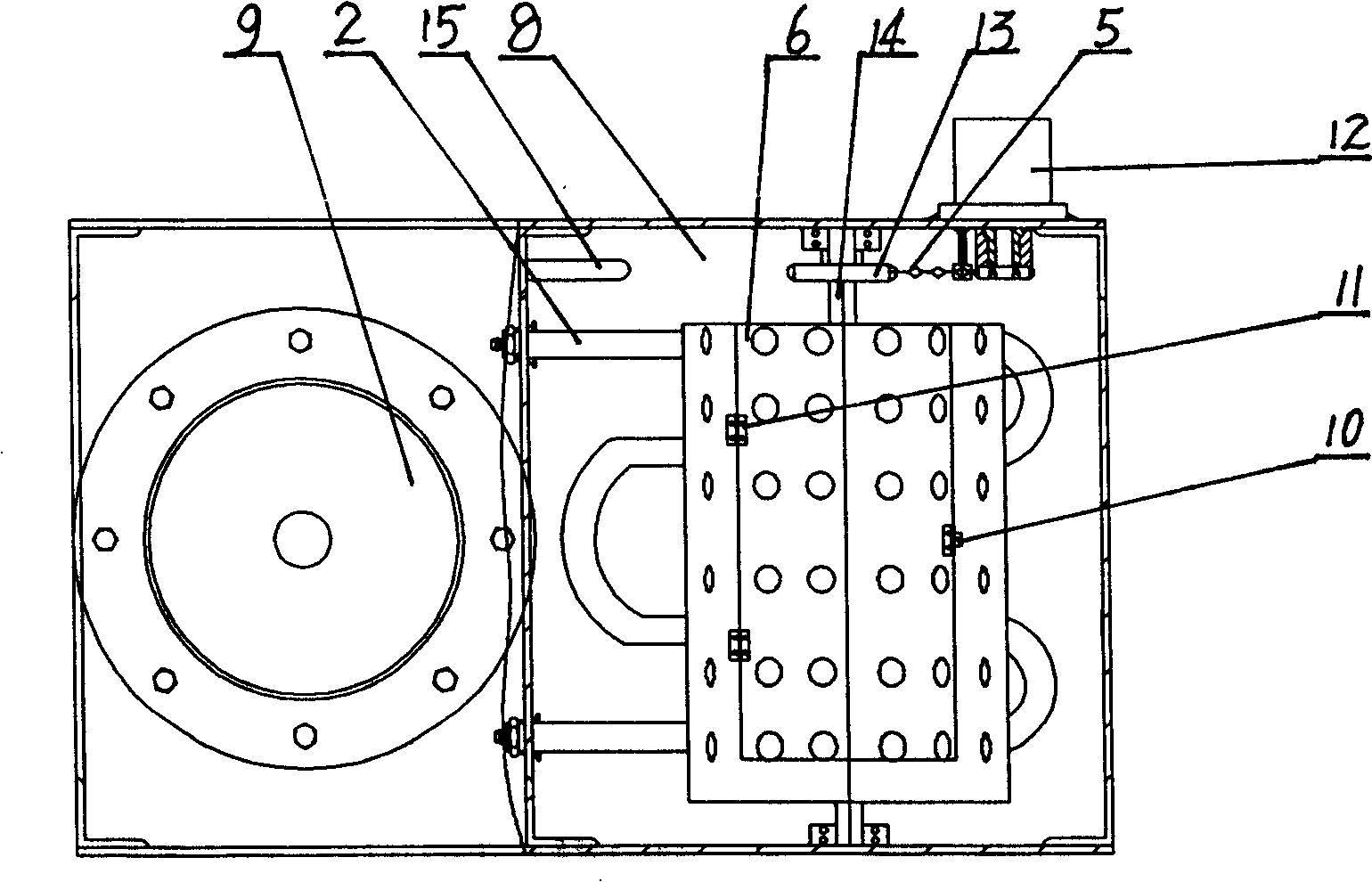

The invention relates to a machining part degumming device, belonging to the mechanical processing technical field, namely the invention provides a degumming device, which is provided with high productivity and does not affect the permanent magnet performance. The degumming device comprises a body; a rotating cage provided with a flip cover is arranged inside a body cavity; a chain wheel arrangedon a shaft of the rotating cage is connected with a motor through a chain; a sealing cover is arranged in the body part above the rotating cage; an electrical heating tube is arranged in the body part under the rotating cage; a dirt-drainage valve is arranged at the bottom of the body; and condenser arranged outside the body is connected with the body cavity.

Description

degumming device Technical field: The invention belongs to the technical field of mechanical processing and is mainly used for a degumming device of machined parts. Background technique: At present, in the process of permanent magnet processing, numerical control wire cutting machines and slicers are mostly used for mechanical processing to ensure its shape and dimensional accuracy. In order to improve machining efficiency and material utilization, multiple blanks (bars) are bonded to cheap and easy-to-process materials (such as plexiglass, hard plastic) with superglue, and processed together. The semi-finished products after processing are still bonded together, and the adhesive needs to be removed before the next step of finishing can be performed. Now, the method of taking off the adhesive generally adopts the method of boiling in hot water for a long time. The application practice in recent years shows that there are many problems in this method of degumming, which ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B08B3/10B08B3/06B01D5/00B08B3/08

Inventor 赵清娄桂艳

Owner SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com