Oil pumping machine and its control system and control method

A technology of control system and pumping unit, applied in the direction of control system, vector control system, motor generator control, etc., can solve the problems of energy saving and consumption reduction and increase production, and achieve increased production capacity, high degree of intelligence, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] 1. Pumping unit

[0040] The pumping unit of the present invention is composed of two parts: a fully digital asynchronous / synchronous AC servo control system and a motor-driven and mechanical-driven oil pumping system. Transformation of intelligent pumping methods.

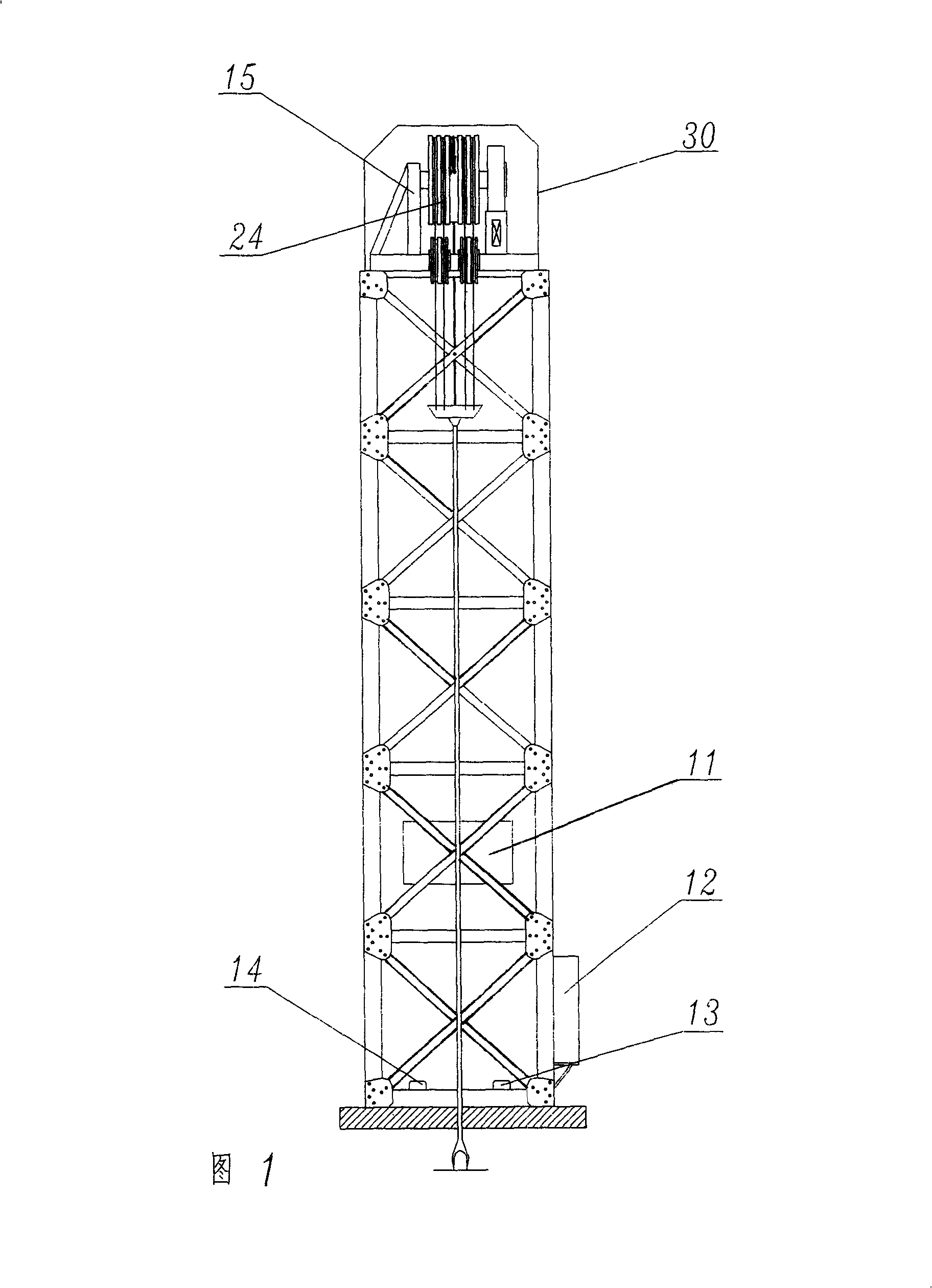

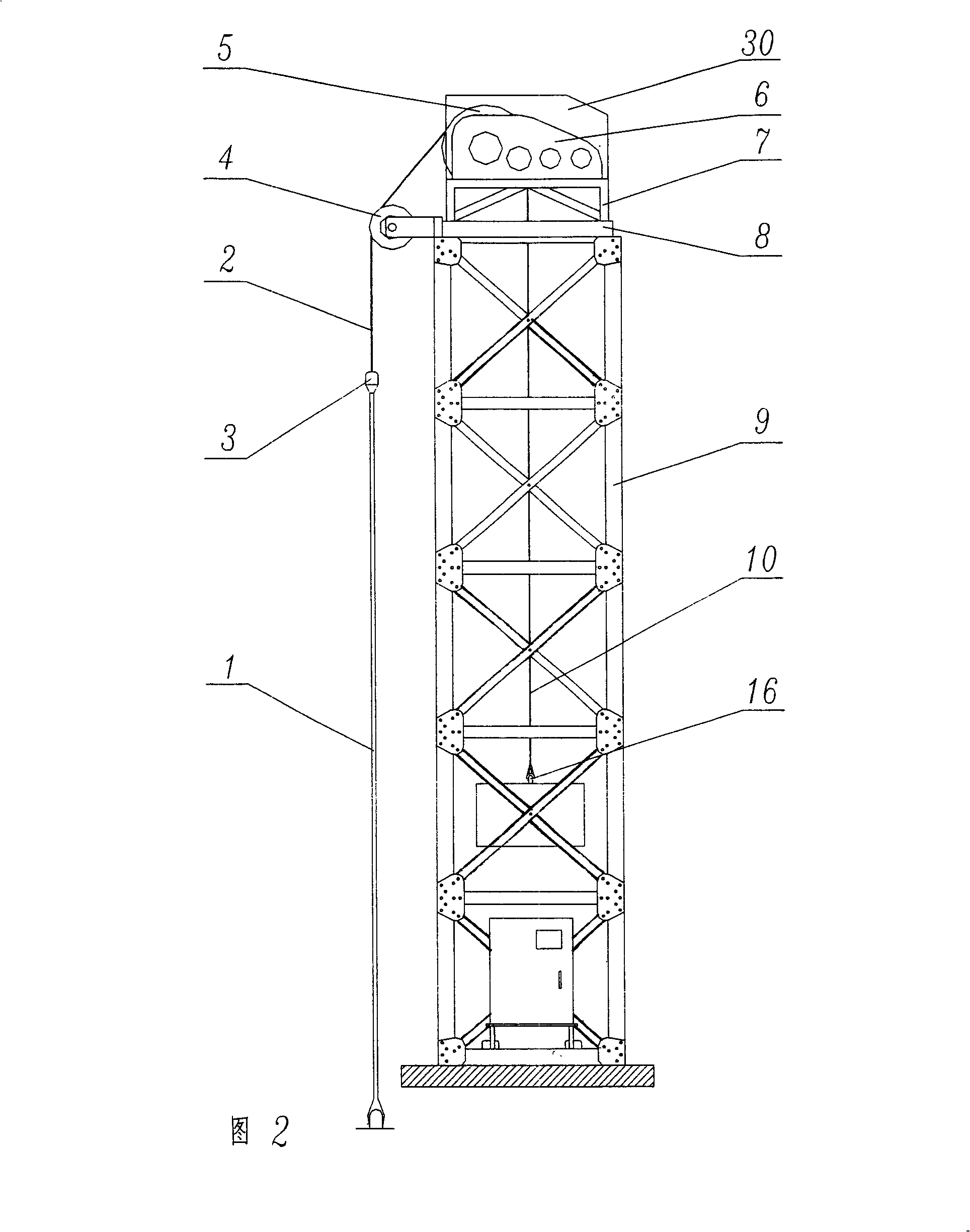

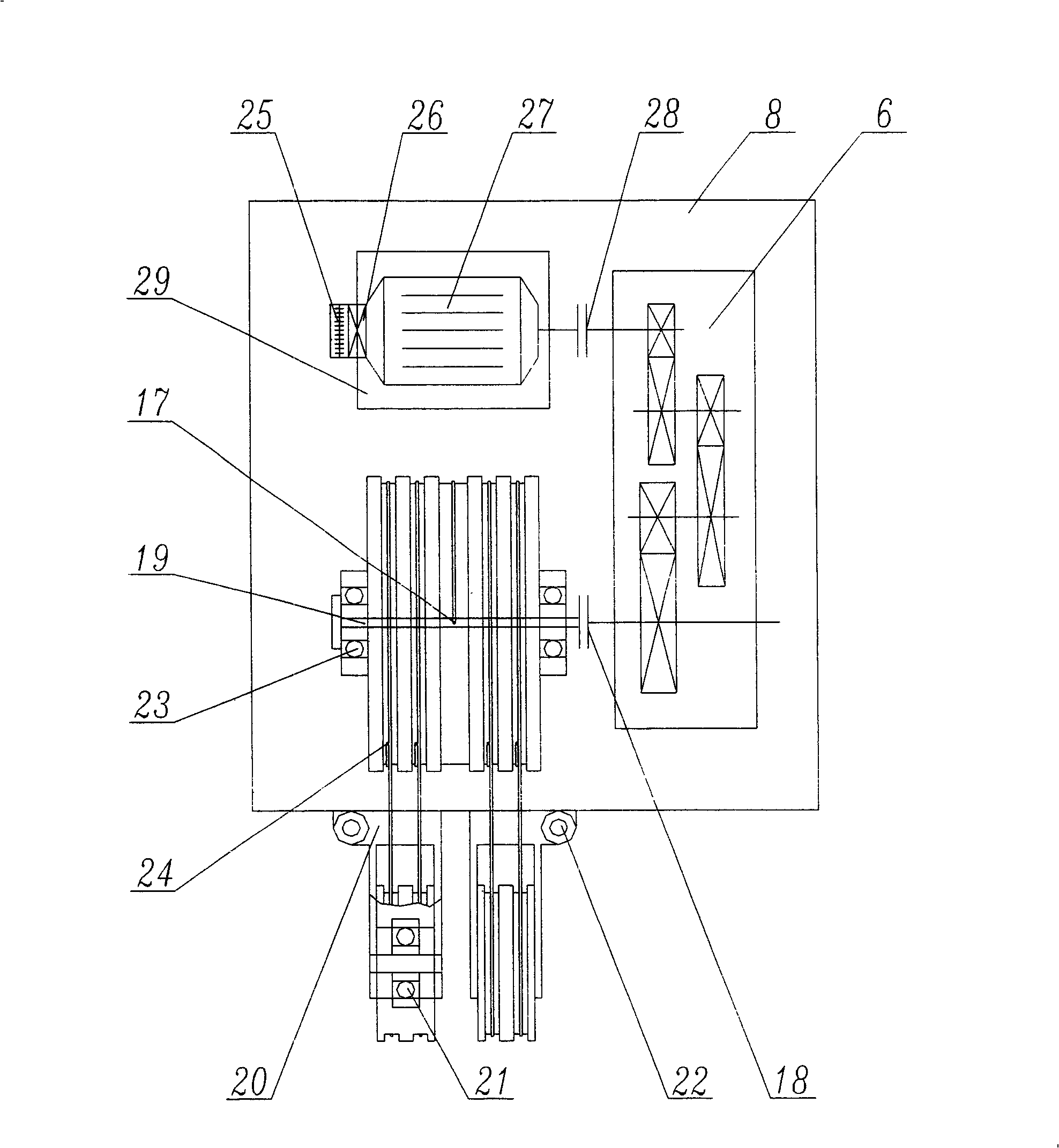

[0041] Referring to accompanying drawings 1-3, the motor drive and mechanical transmission system includes a combined main frame, a sucker rod, a motor, a motor control system, a transmission device and a counterweight, and the wire rope hole is pulled by the counterweight on the circumference of the rewinding wheel 5 The counterweight traction steel wire rope 10 drawn from 17 and the counterweight traction steel wire rope fastener 16 jointly fasten and lock the counterweight 11 to form a counterweight running traction system (Fig. 1).

[0042] At the same time, the sucker rod 1 is connected with the tractor 3, and after being connected to the head end of the suspension rope 2, it is coiled on the circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com