Vertical aerogenerator blade assembly and method for wind power generation variable coiling combination

A technology of wind power generators and blade groups, which is applied in the direction of wind power motor combination, wind power engine control, and wind power power generators at right angles to the wind direction, and can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

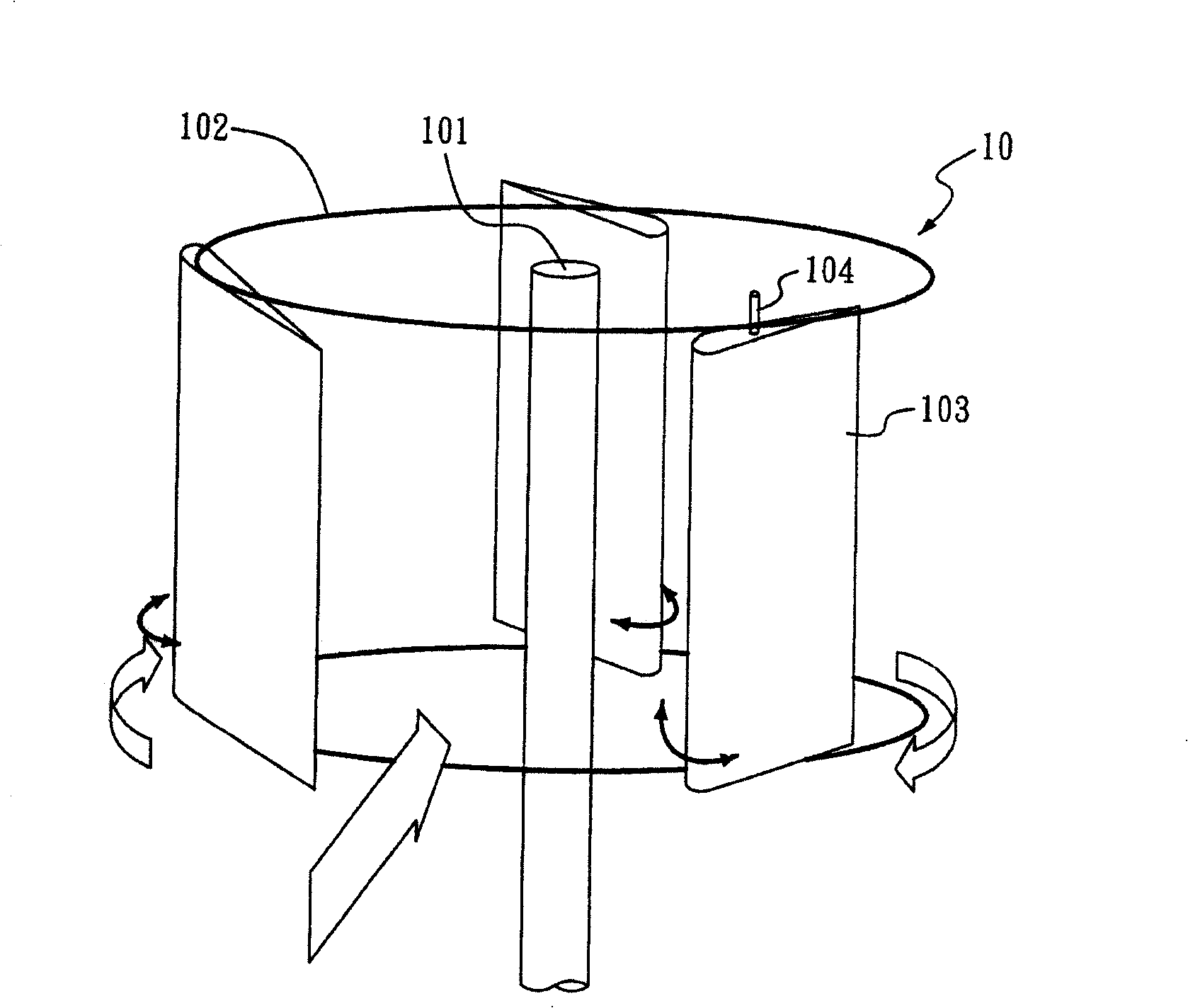

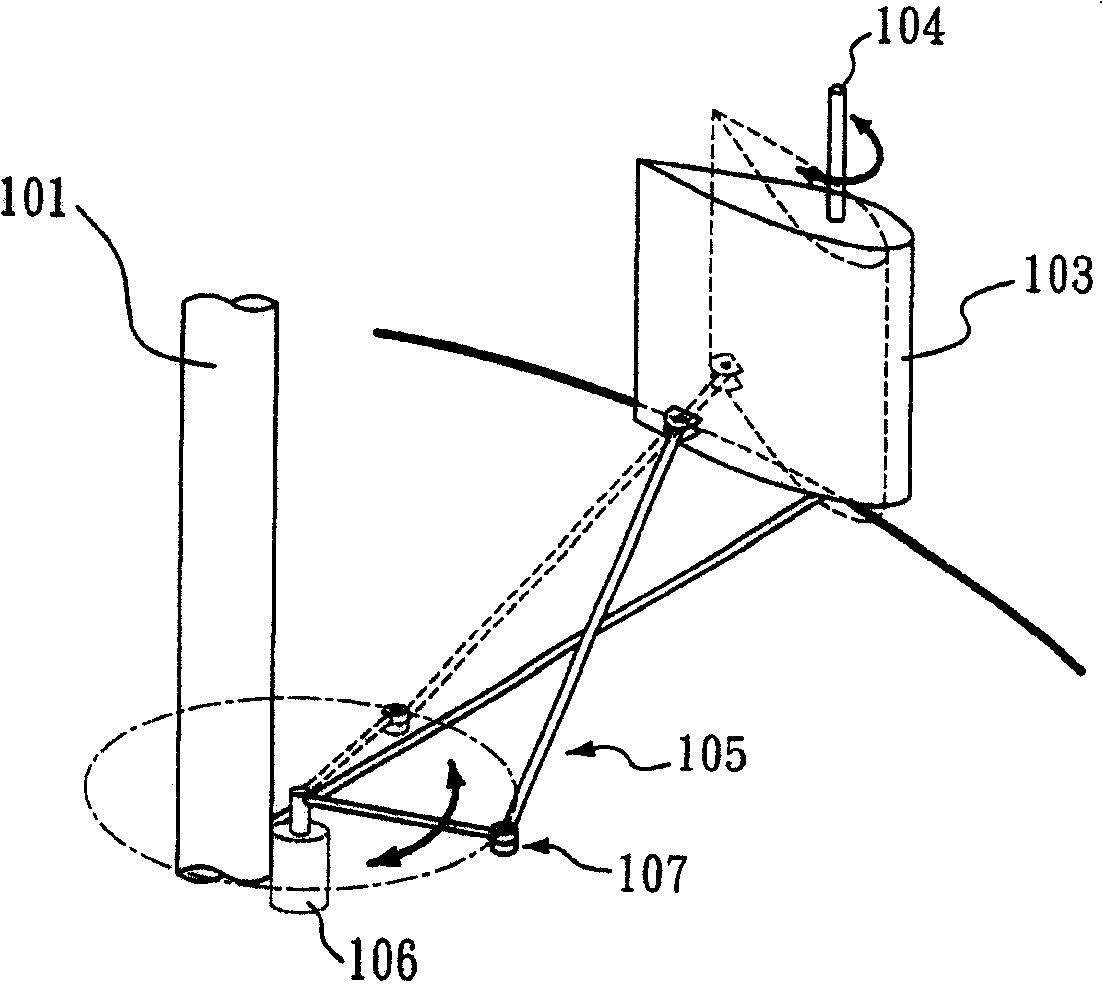

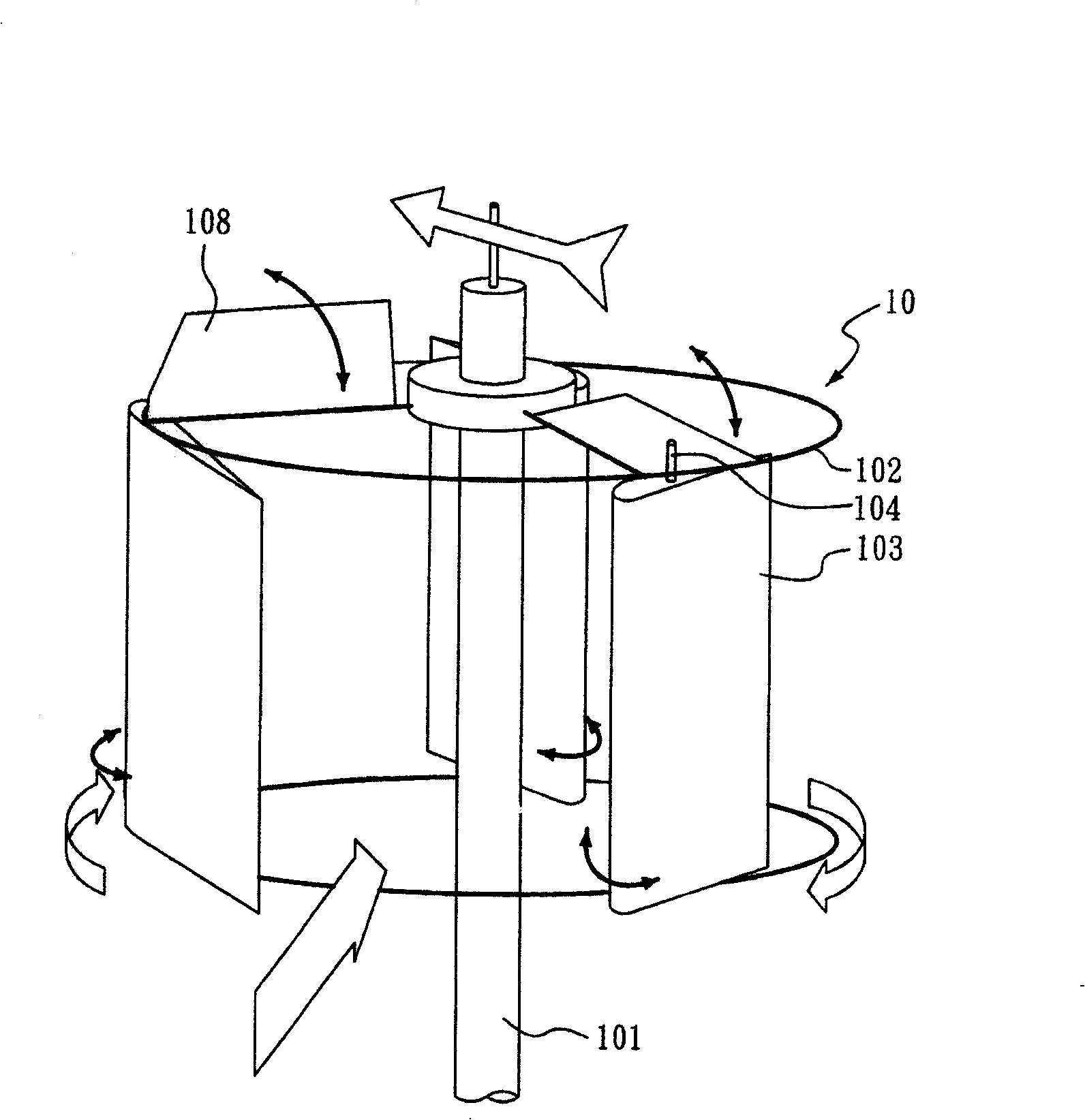

[0034] figure 1 It is a schematic diagram showing the blade set 10 of the improved vertical wind power generator of the present invention, the blade set 10 is supported on a vertical shaft 101 that drives a generator (not shown in the figure) to rotate, and the blade set 10 includes a A rotating frame 102, and a plurality of vertical blades 103 arranged on the rotating frame 102. Each of the blades 103 has a vertical rotating shaft 104 and is pivotably disposed on the rotating bracket 102 . Such as figure 2 As shown, each blade 103 is additionally provided with an adjustable connecting rod 105, which can be connected to the rotating bracket 102, so that each blade 103 can be rotated and adjusted around its vertical rotation axis 104, so as to maintain the distance between each blade 103 and the windward surface. The best angle of attack (Pitch Angle).

[0035] The so-called angle of attack of the blade to the airflow is defined as the angle between the front and rear edges...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com