Circulation type high-efficiency standard-improving system

A circulatory and high-efficiency technology, applied in water/sludge/sewage treatment, filtration treatment, sedimentation treatment, etc., can solve problems such as liquid level fluctuation, limit the load capacity of anoxic tanks, flush out anaerobic bacteria, etc., to achieve stable The effect of load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment discloses a circulating high-efficiency upgrading system, or a water treatment system, or a waste water treatment system. Without causing conflicts or contradictions, the overall and preferred implementations of other embodiments / or part of the content may be used as a supplement to this embodiment.

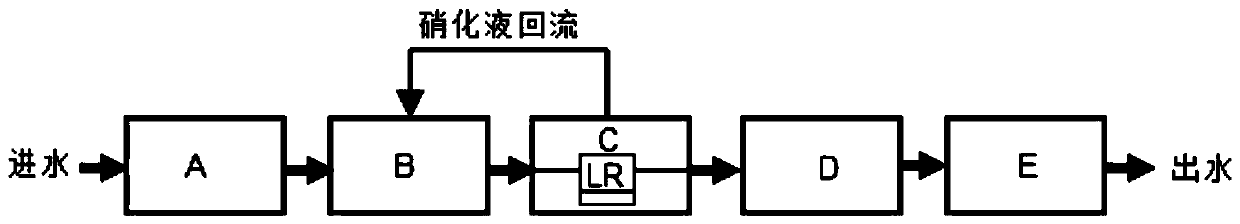

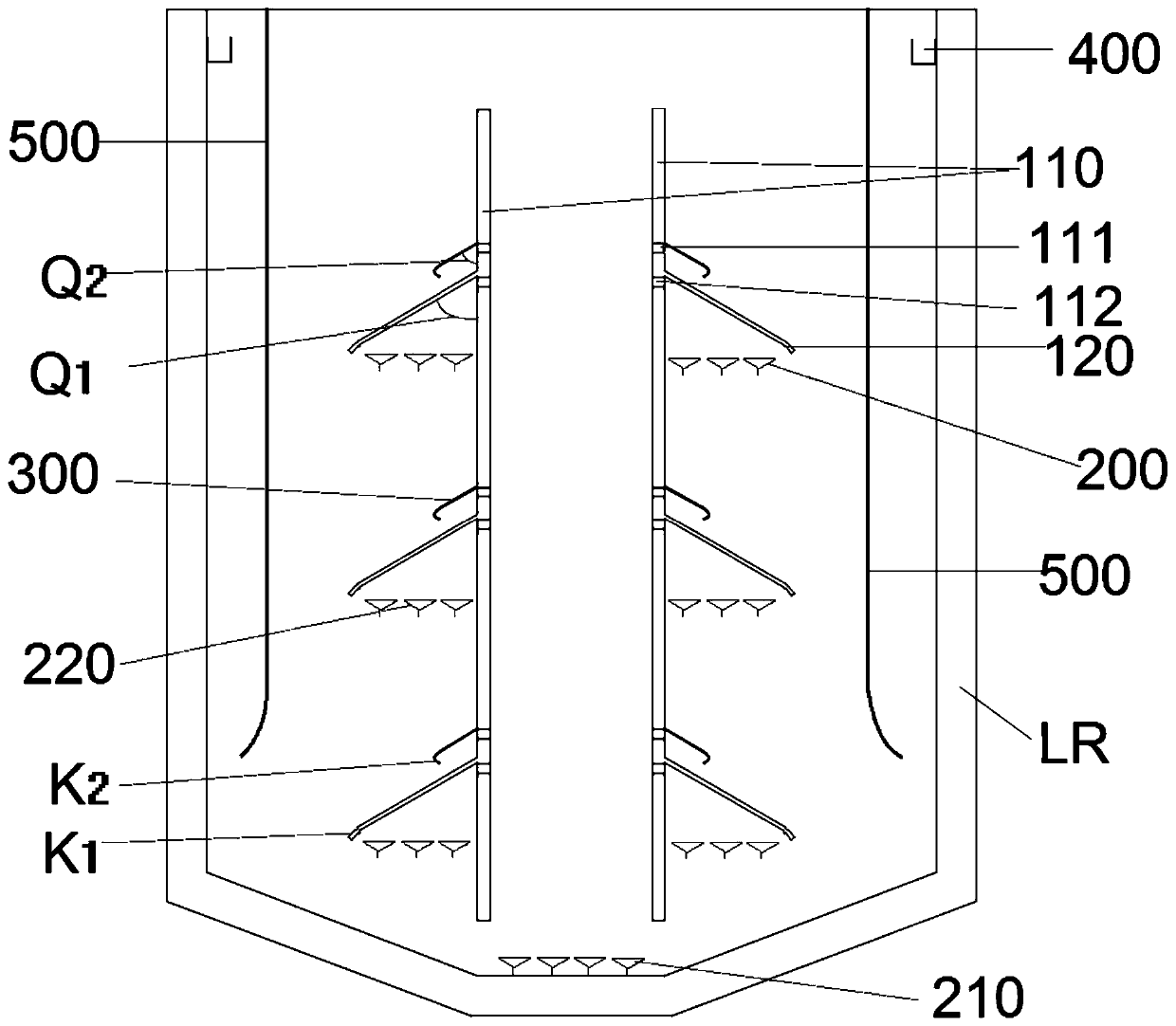

[0045] According to a preferred embodiment, the system may include at least one of the regulating pond A, the anoxic pond B, the aerobic pond C, the sedimentation pond D and the clear water pond E. A loop oxidation reactor LR may be arranged in the aerobic pool C. The water in the adjustment pool A can be filtered into the anoxic pool B through the grid. The aerobic tank C transfers the water in the anoxic tank B to the sedimentation tank D after efficient upgrading. At the same time, the nitrifying liquid in the aerobic tank C and the sludge in the sedimentation tank D can circulate back to the anoxic tank B. The clear water in the sedimentation tank D...

Embodiment 2

[0072] This embodiment may be a further improvement and / or supplement to Embodiment 1, and repeated content will not be repeated here. In the case of no conflict or contradiction, the whole and / or part of the content of the preferred implementations of other embodiments may serve as supplements to this embodiment.

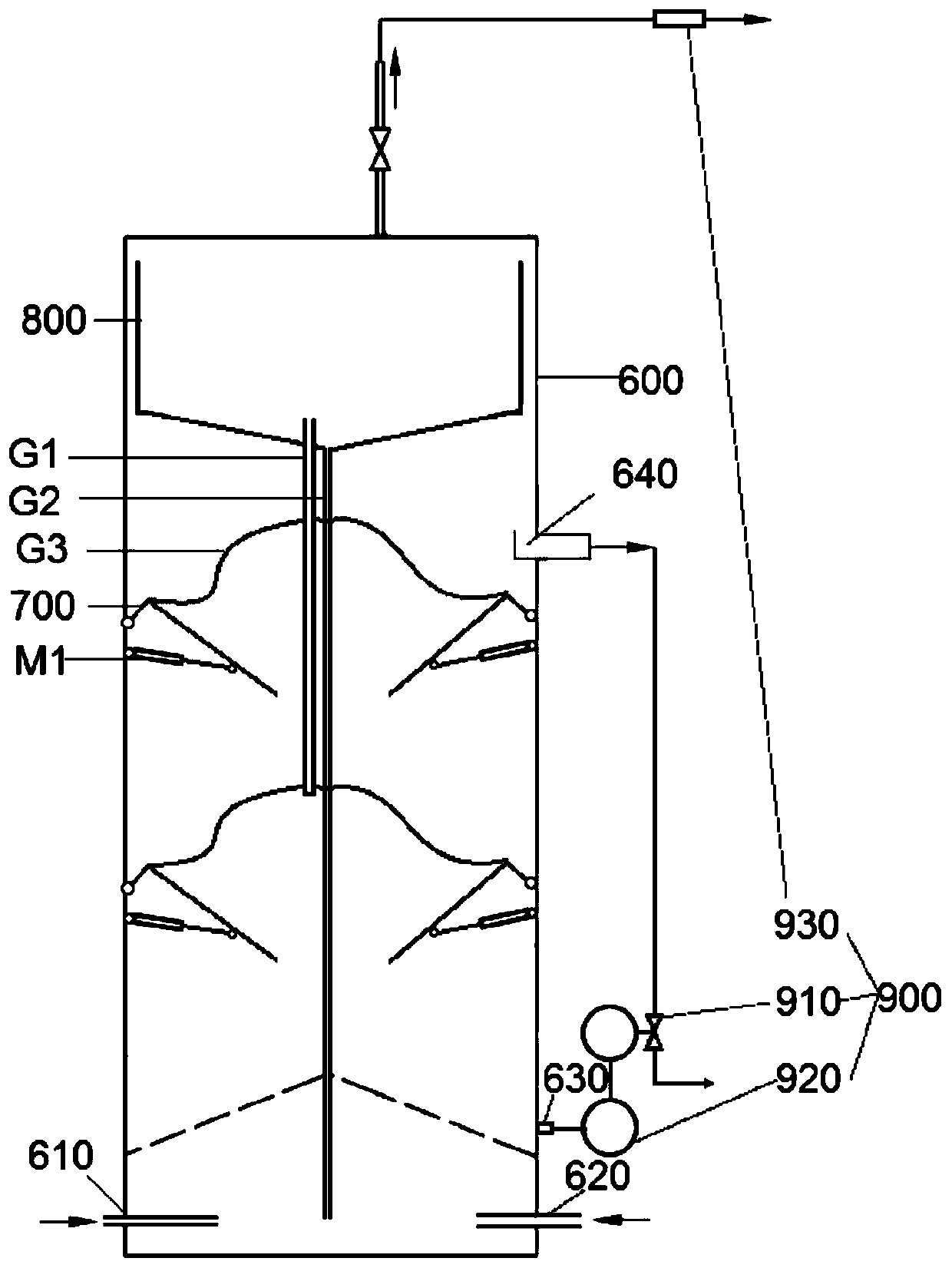

[0073] According to a preferred embodiment, an anoxic pool B may include: a reaction vessel 600, a first liquid inlet 610, a second liquid inlet 620, a liquid outlet 630, at least one gas collector 700, at least one gas-liquid At least one of the separator 800, at least one ascending pipe G1 and the descending pipe G2.

[0074] According to a preferred embodiment, an anoxic tank B may include: a reaction vessel 600, a first liquid inlet 610 for introducing the liquid from the adjustment tank A into the reaction vessel 600 during operation, The liquid from the aerobic tank C is introduced into the second liquid inlet 620, the liquid outlet 630, at least one gas col...

Embodiment 3

[0086] This embodiment may be a further improvement and / or supplement to Embodiment 1, 2 or their combination, and repeated content will not be repeated. In the case of no conflict or contradiction, the whole and / or part of the content of the preferred implementations of other embodiments may serve as supplements to this embodiment. This embodiment discloses a circulating high-efficiency upgrading method, or a water treatment method, or a wastewater treatment method, which can be realized by the system of the present invention and / or other replaceable components. For example, the method of the present invention is realized by using various components in the system of the present invention.

[0087] According to a preferred embodiment, the method may include: using the aforementioned system for water treatment. According to a preferred embodiment, the method may include: using the aforementioned loop oxidation reactor LR for water treatment.

[0088] According to a preferred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com