Velocity synchronous self-adapting reversed control method for multi-motor system of IC material linear cutting machine

An adaptive controller and adaptive inverse technology, applied in the direction of adaptive control, electrical program control, digital control, etc., can solve problems such as large tracking error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

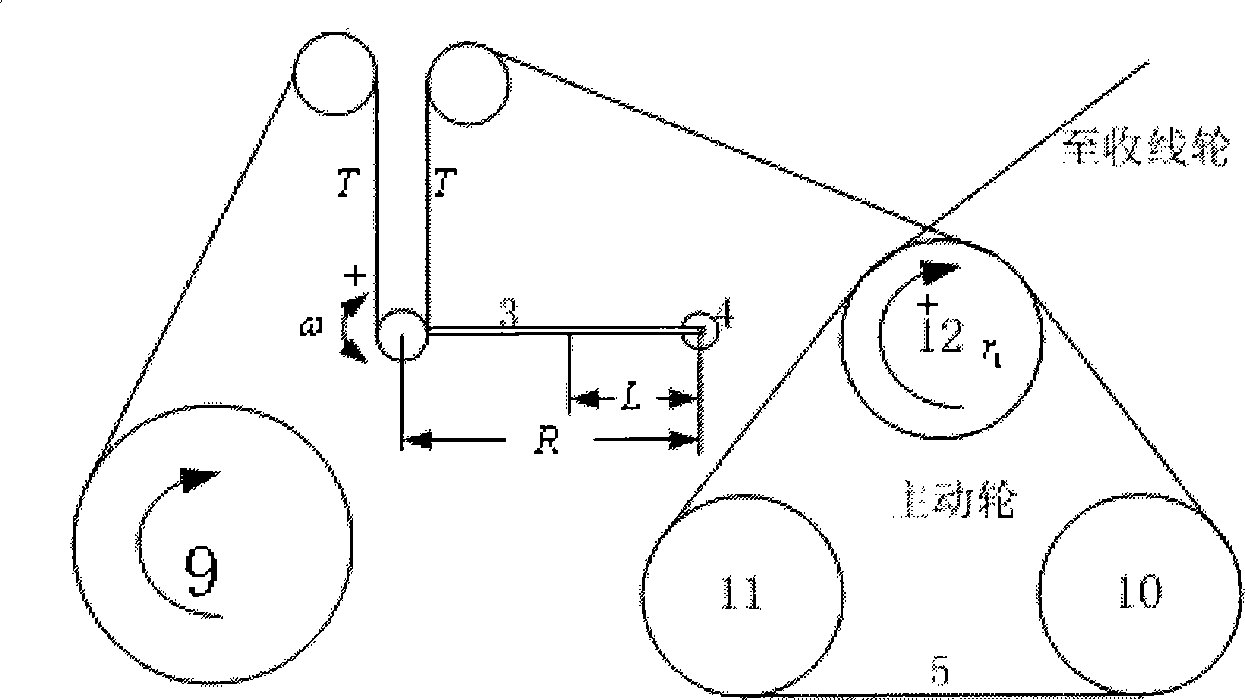

[0062] In the example, such as figure 1 , 4. For the control accuracy of shaftless transmission, the speed control device of the multi-motor system of the IC material wire cutting machine tool includes:

[0063] Motion controller 13, choose the MP2300 motion controller of YASKAWA company, to realize the control of the line follow-up system;

[0064] The slave motors include the take-up motor and the pay-off motor 2, all of which adopt the ΣIII type servo driver and the ΣII type servo motor of YASKAWA company; the tension motor 4, the output torque applies tension to the steel wire; in order to record the tension, the pendulum 3 is balanced The position of the point, the speed sensor adopted by the two tension motors selects a 17-bit absolute value type photoelectric encoder 7;

[0065] The tension pendulum 3 arranged between the pay-off roller and the take-up roller of the cutting machine tool is used to adjust the speed synchronization between the two;

[0066] The absolute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com