Electrostatic ceramic fine filter

A filter and ceramic technology, which is applied in the field of separation, can solve the problems of insufficient filter precision and easy clogging, and achieve the effect of reducing the clogging probability of the filter element, not easy to clog, and improving the filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

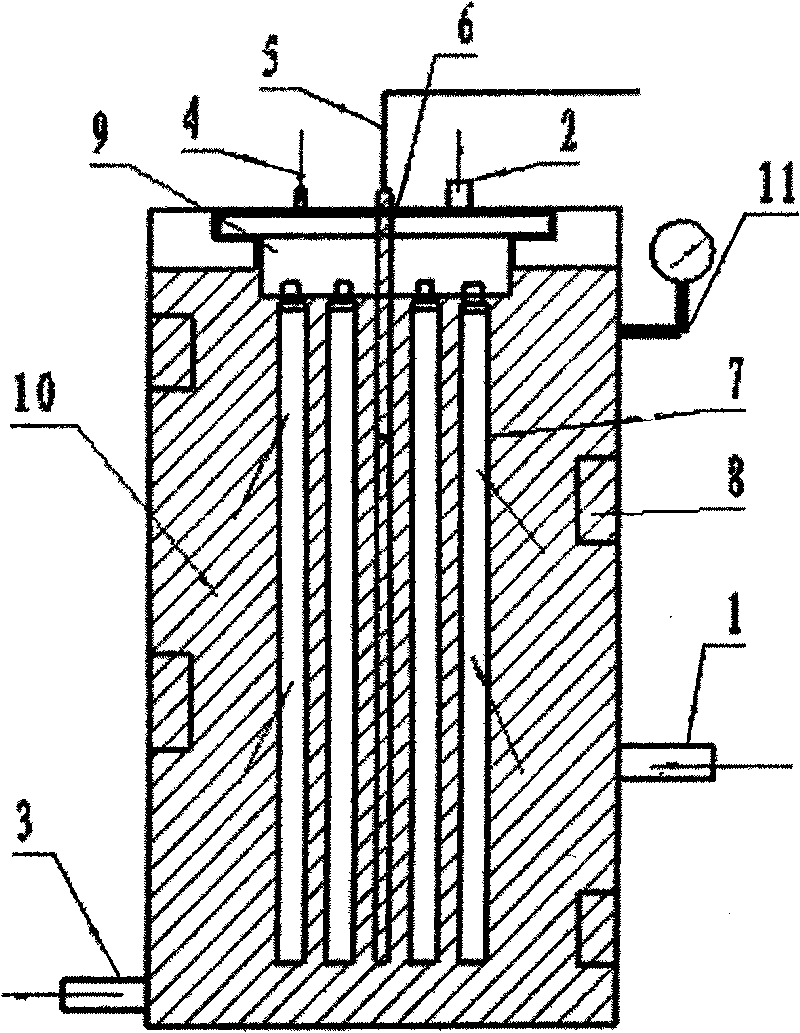

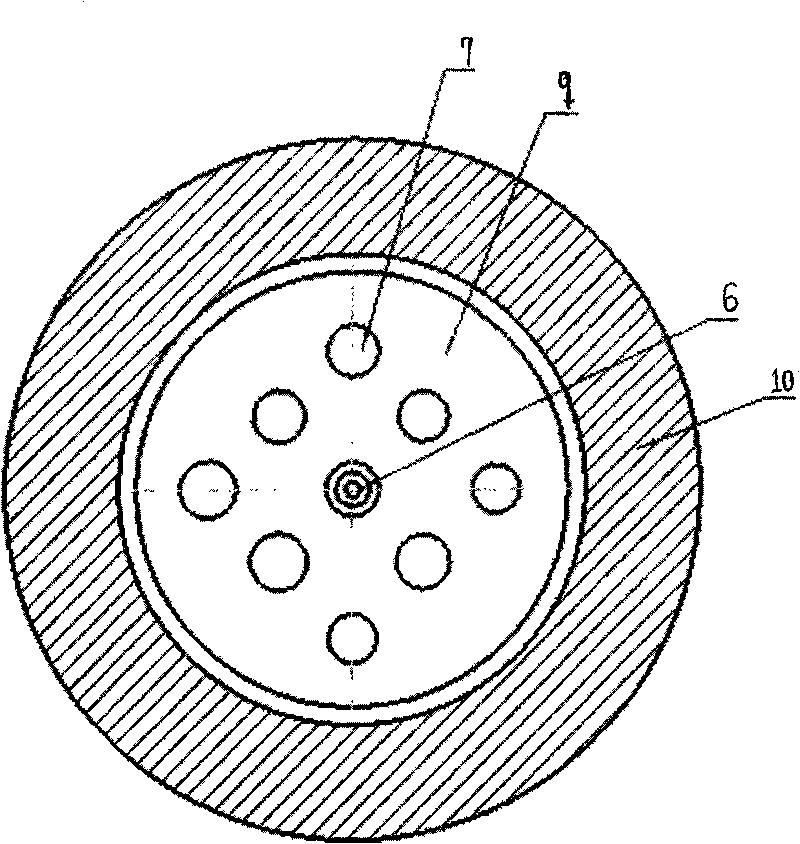

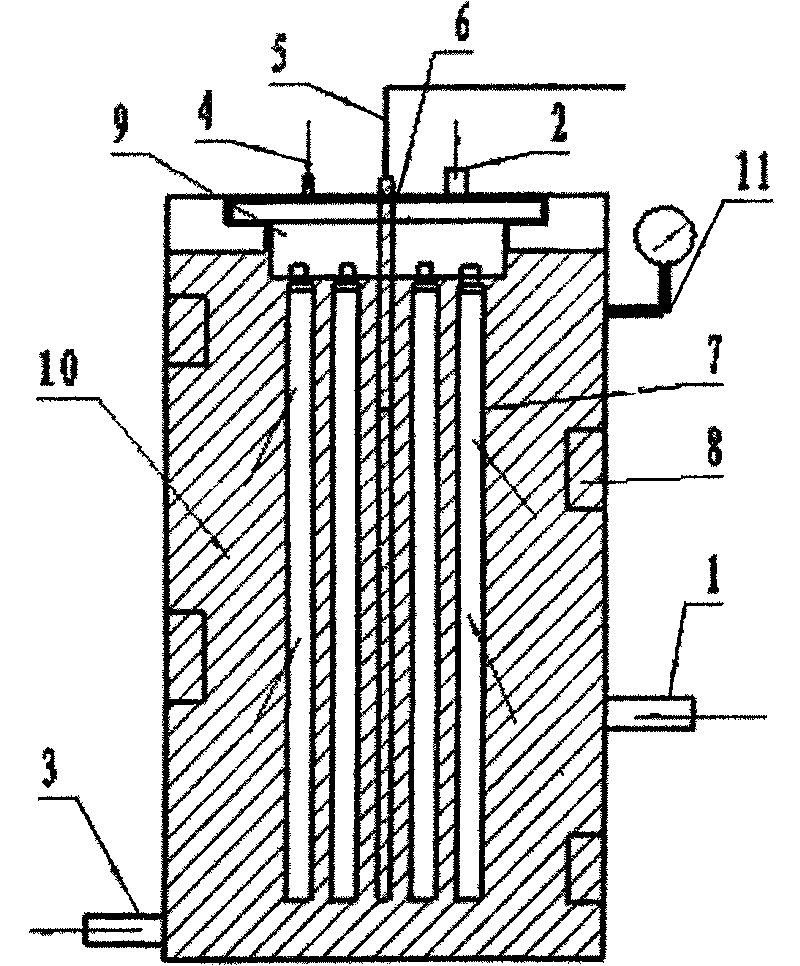

[0010] Such as figure 1 , 2 As shown, the electrostatic ceramic fine filter includes a filter cylinder, an electrostatic generator (static electrode), a porous honeycomb sponge body, and an airflow-ultrasonic cleaning device. There is an oil inlet 1 and an oil discharge port 3 on the filter cylinder, and a porous honeycomb sponge body 10 is installed in the filter cylinder body. The porous honeycomb sponge body 10 is ring-shaped and has a plurality of ceramic filter rods 7 and static electrodes 6 in its center. The porous honeycomb sponge body is tightly applied to the ceramic filter element group. The ceramic filter rod 7 and the static electrode 6 are fixed on the filter element carrying bracket 9, and the filter element carrying bracket 9 is sealed and installed on the opening of the filter cylinder, and the oil outlet 2 is opened on the filter element carrying bracket 9. A pressure sensor 11 is installed on the filter cylinder, and an ultrasonic vibrator 8 is installed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com