Spin type atomizer

A spray device and spin-type technology, which is applied in safety devices, mining equipment, earthwork drilling and mining, etc., can solve the problems of large spray water consumption, many nozzles, water accumulation in roadways, etc., to eliminate rock dust and coal dust, expand Spray effect, extended coverage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

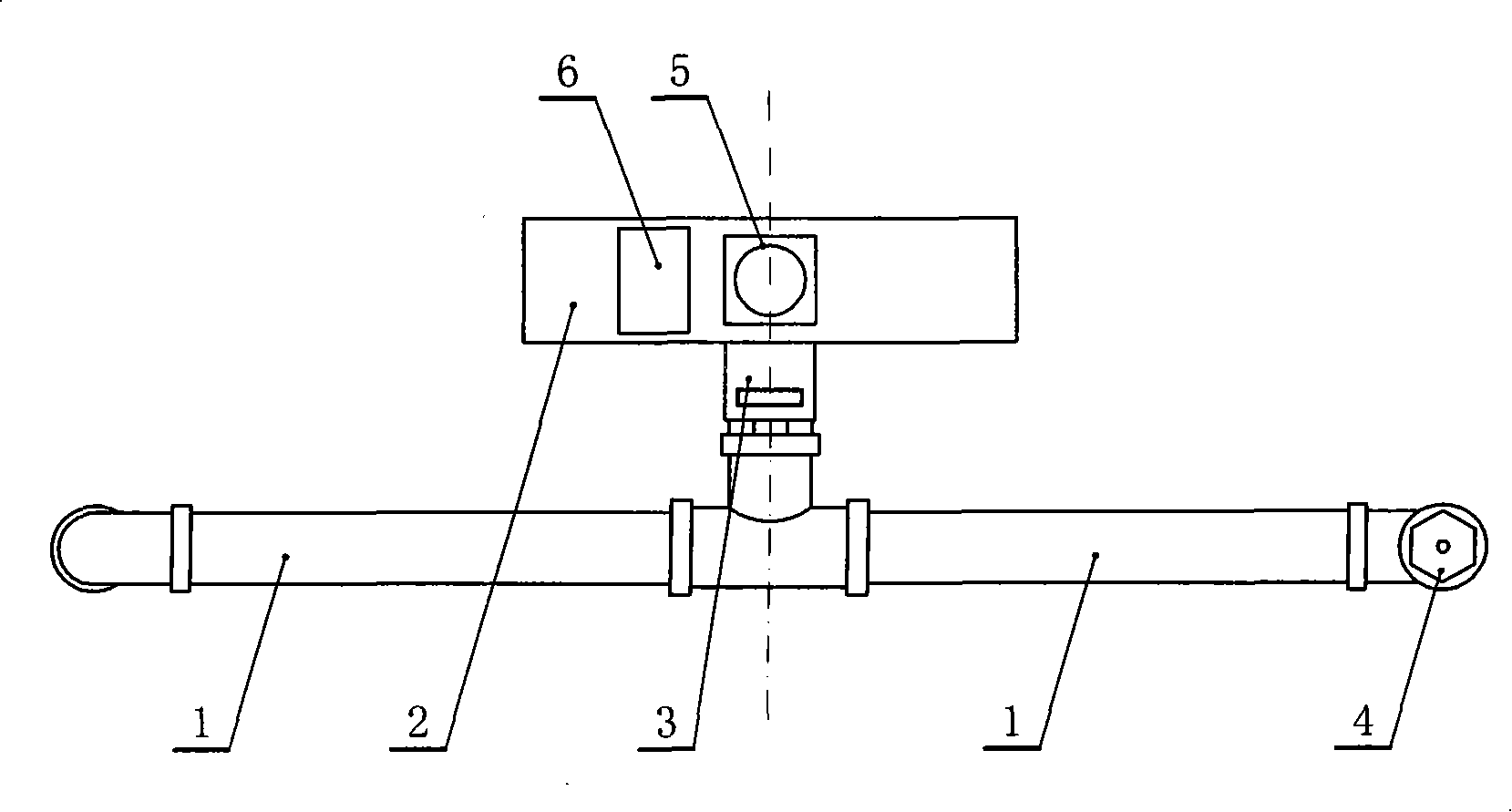

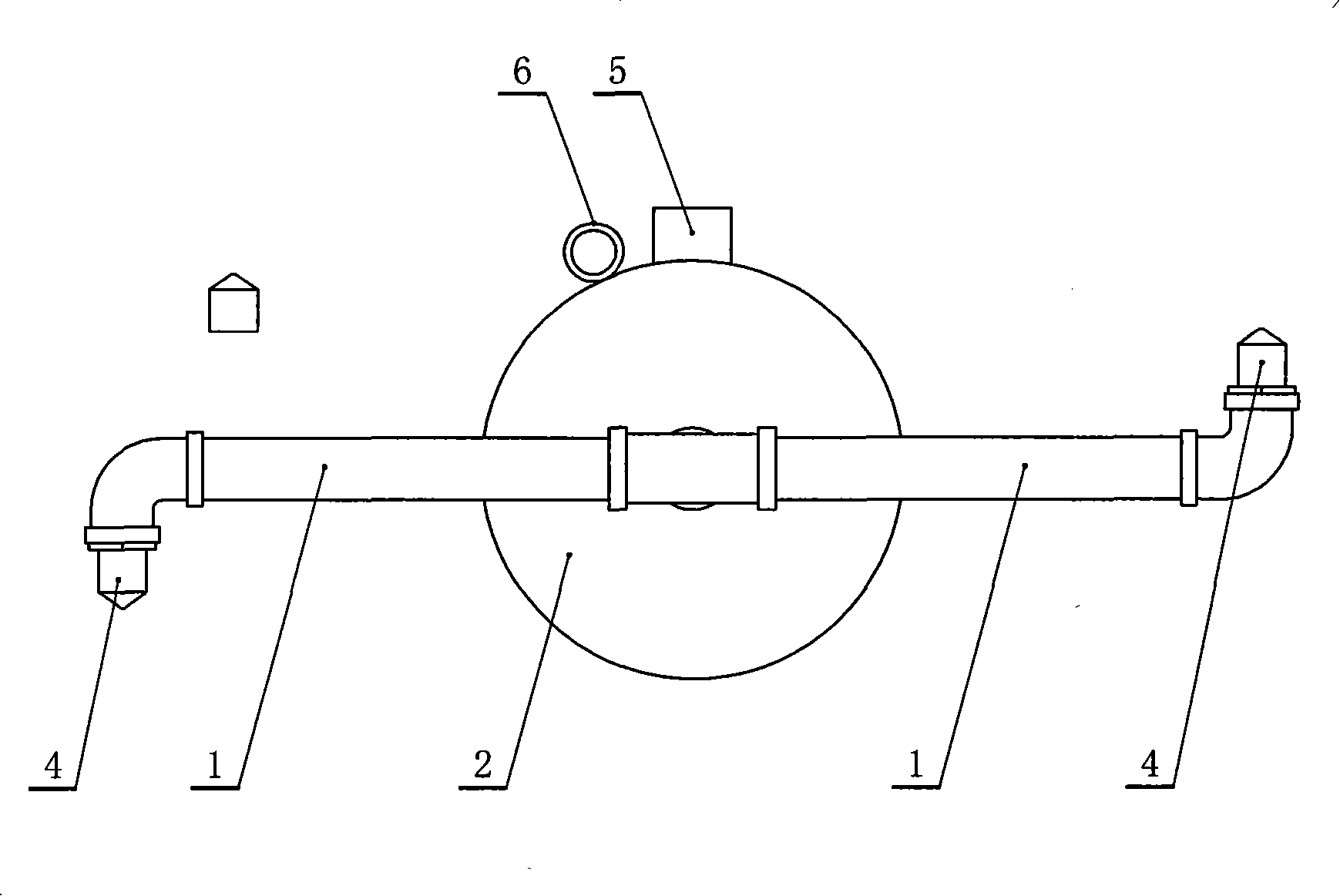

[0016] A spin spray device, such as figure 1 , figure 2 As shown, it includes a water storage 2, the water storage 2 has a water inlet 5, the water storage 2 is fixedly connected with a hanging hook 6, the side wall of the water storage 2 is connected with a rotary joint 3, and the rotary joint 3 is installed There is a swivel arm 1, and the two ends of the swivel arm 1 are symmetrically equipped with nozzles 4, the nozzles of the two nozzles 4 are facing opposite, and the nozzles of the nozzles 4 are perpendicular to the axis of the rotary joint 3.

Embodiment 2

[0018] A spin spray device, such as image 3 As shown, it includes a water storage device 2, the water storage device 2 has a water inlet 5, the water storage device 2 is fixedly connected with a hanging hook 6, and the two parallel sides of the water storage device 2 are respectively connected with a rotary joint 3 The swivel arms 1 are installed on the two swivel joints 3, and the two ends of the swivel arms 1 are symmetrically installed with the nozzles 4. The nozzles of the two groups of nozzles 4 are facing opposite to each other, and the nozzles of the nozzles 4 are all different from the axis of the swivel joint 3. face vertical.

Embodiment 3

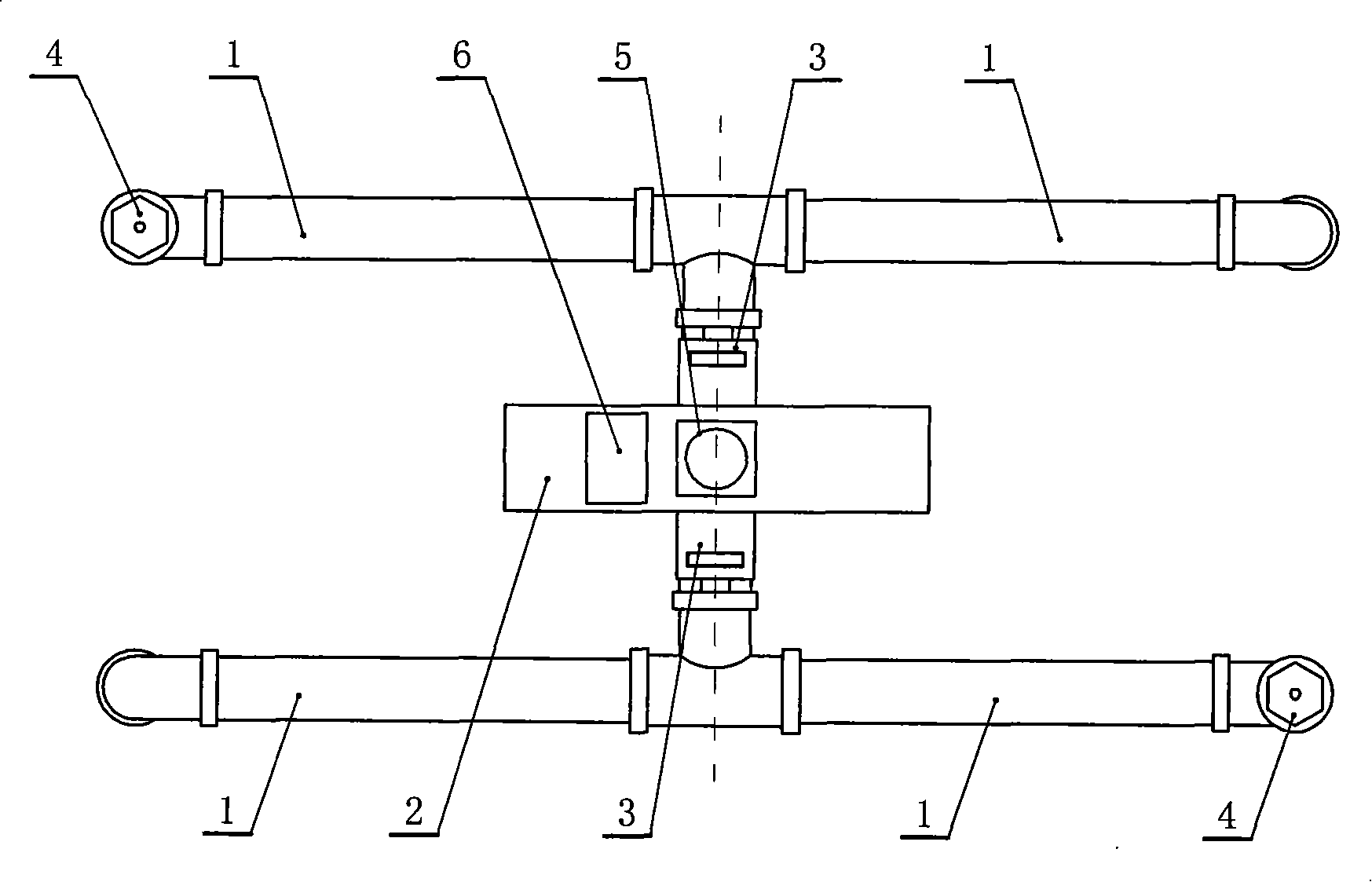

[0020] A spin spray device, such as Figure 4 As shown, it includes a water storage 2, the water storage 2 has a water inlet 5, the water storage 2 is fixedly connected with a hanging hook 6, the side wall of the water storage 2 is connected with a rotary joint 3, and the rotary joint 3 is installed There is a connecting pipe 7, and the two ends of the connecting pipe 7 are respectively equipped with swing arms 1, the two swing arms 1 are parallel to each other, and the two ends of each swing arm 1 are symmetrically installed with nozzles 4, and the nozzles of the two groups of nozzles 4 are facing opposite to each other , the nozzles of the nozzles 4 at the same end of the two swivel arms 1 have the same direction, and the nozzles of the nozzles 4 are oriented perpendicular to the axis of the rotary joint 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com