Gas compression method using end-face compression as well as end-face compression type electric drive gas source device

A gas source device and gas compression technology, which is applied to the components of pumping devices for elastic fluids, pump devices, liquid fuel engines, etc., can solve the problems of difficult manufacturing, high gas supply pressure, and unstable airflow, etc. Achieve enhanced adjustability and adaptability, increased pressure, and smooth airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

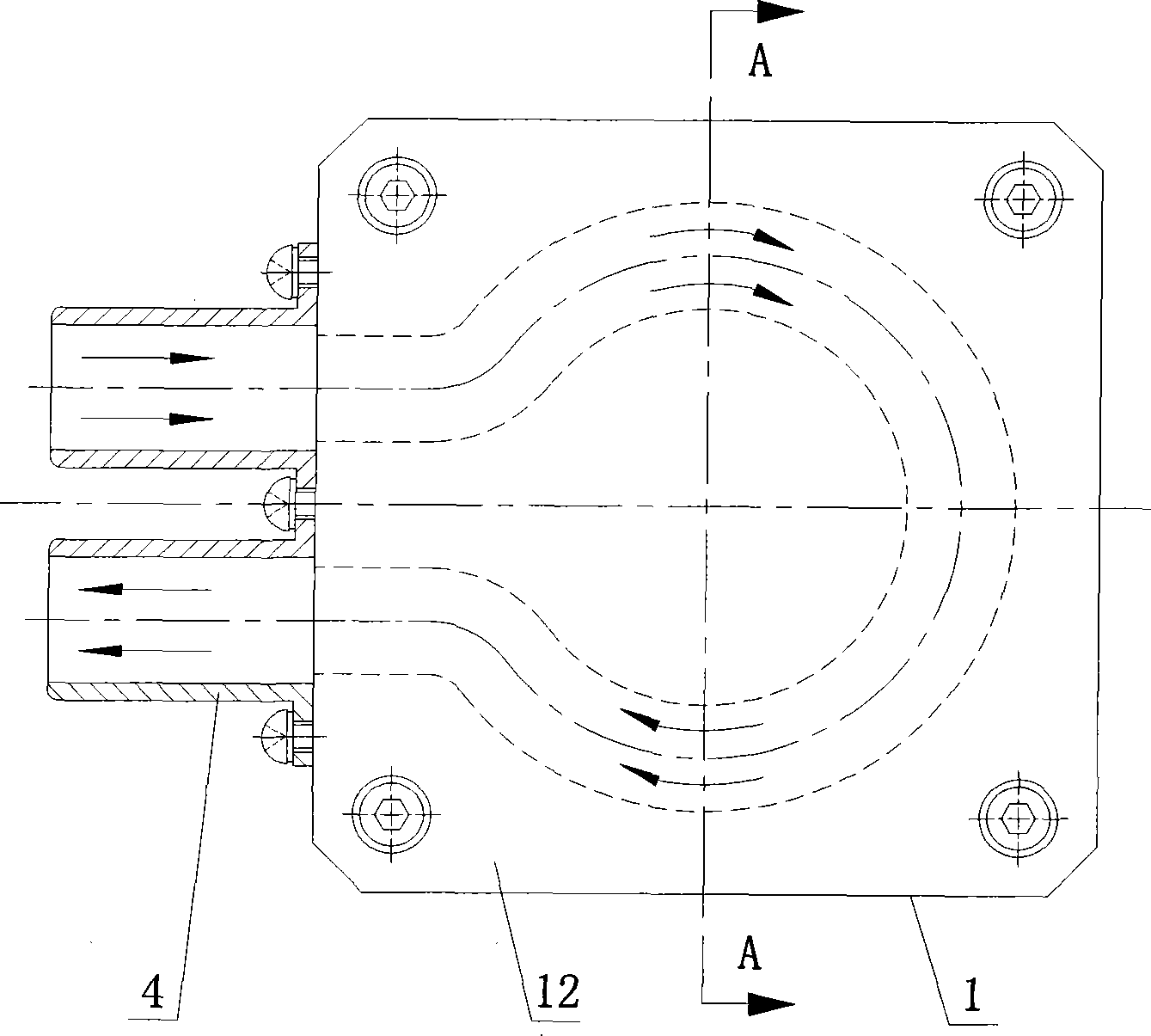

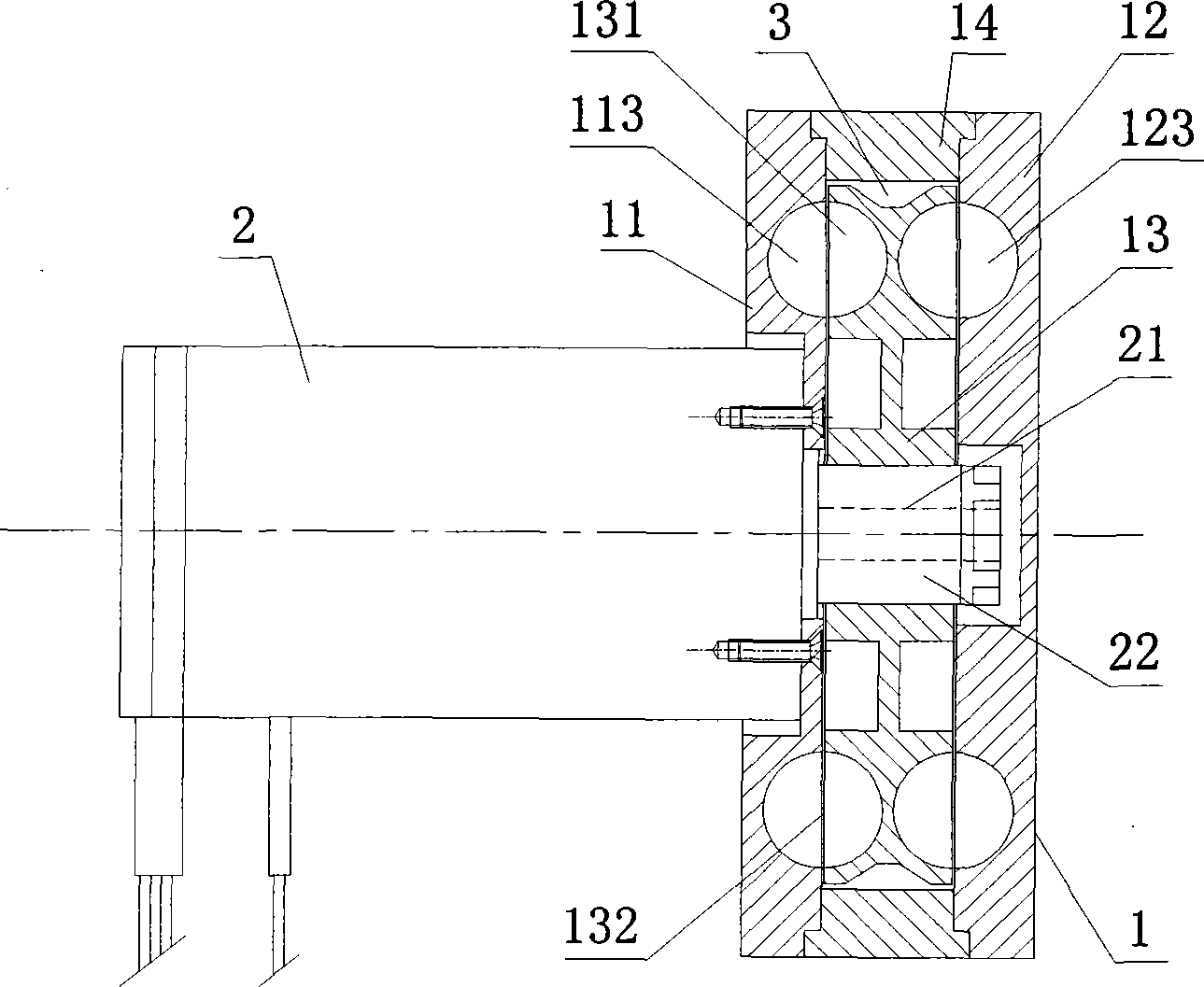

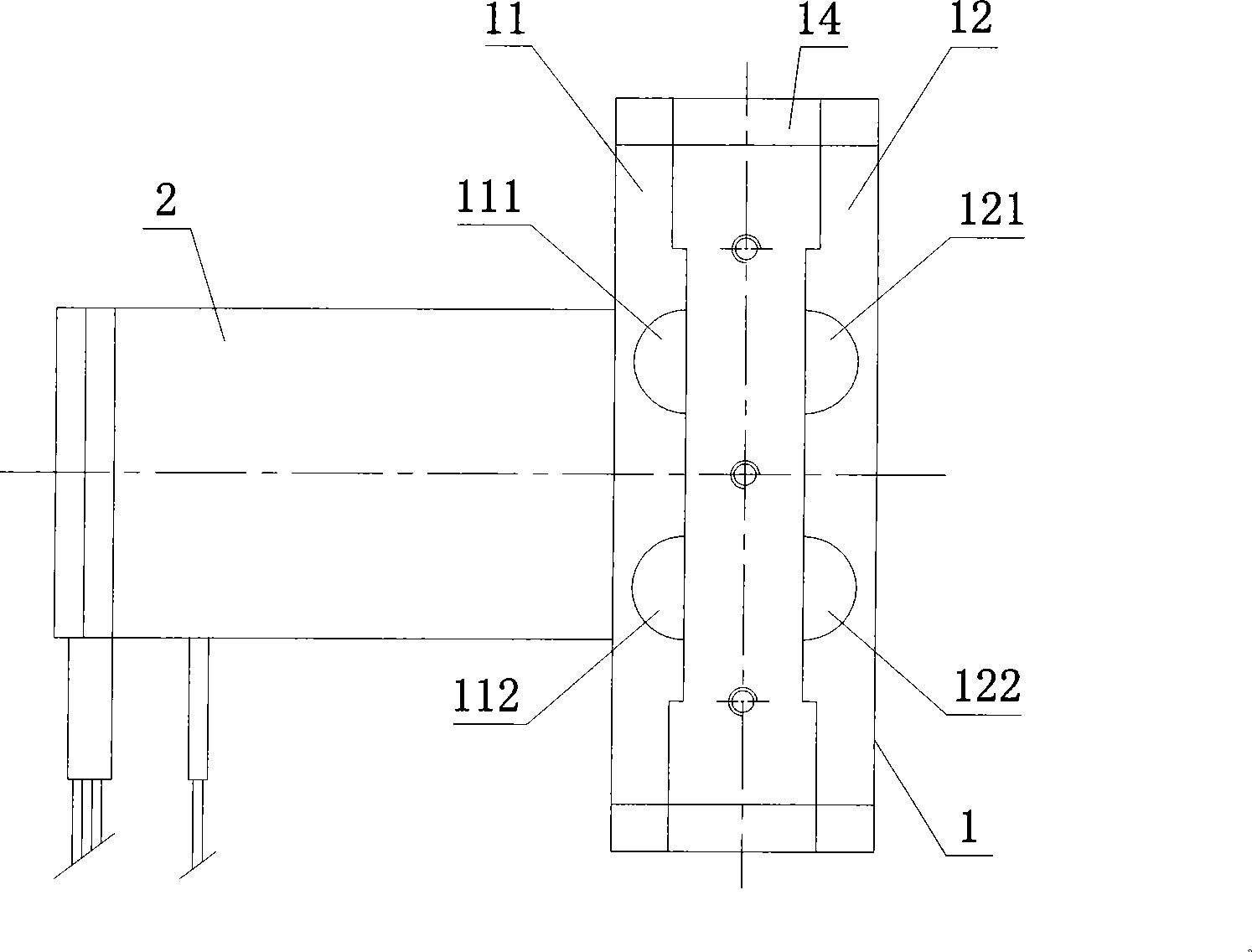

[0047] The gas compression method adopting end surface compression of the present invention, it is to arrange annular groove on both end surfaces of an impeller 13, arrange in the annular groove the blade 132 that evenly divides it into a plurality of compression units 131, this impeller 13 is installed on its In a matching closed cavity 3, air inlet ducts, air outlet ducts, and arc-shaped air guide slots corresponding to the position of the upper ring groove of the impeller 13 are arranged on both inner side walls of the closed cavity 3, and the arc-shaped air guide slots One end of the groove communicates with the air inlet channel, and the other end communicates with the air outlet channel. The motor drives the impeller 13 to rotate at a high speed, so that the gas enters the arc-shaped air guide groove from the air inlet channel, and the gas at both ends of the impeller 13 is compressed by the compression unit 131 Perform multi-stage compression, and then discharge the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com