Lamination type radiator for vehicle

A car radiator, laminated technology, applied in the direction of heat exchanger type, indirect heat exchanger, lighting and heating equipment, etc., can solve the leakage, the difference between the coolant flow and the car radiator flow requirements, affect the core Heat dissipation efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

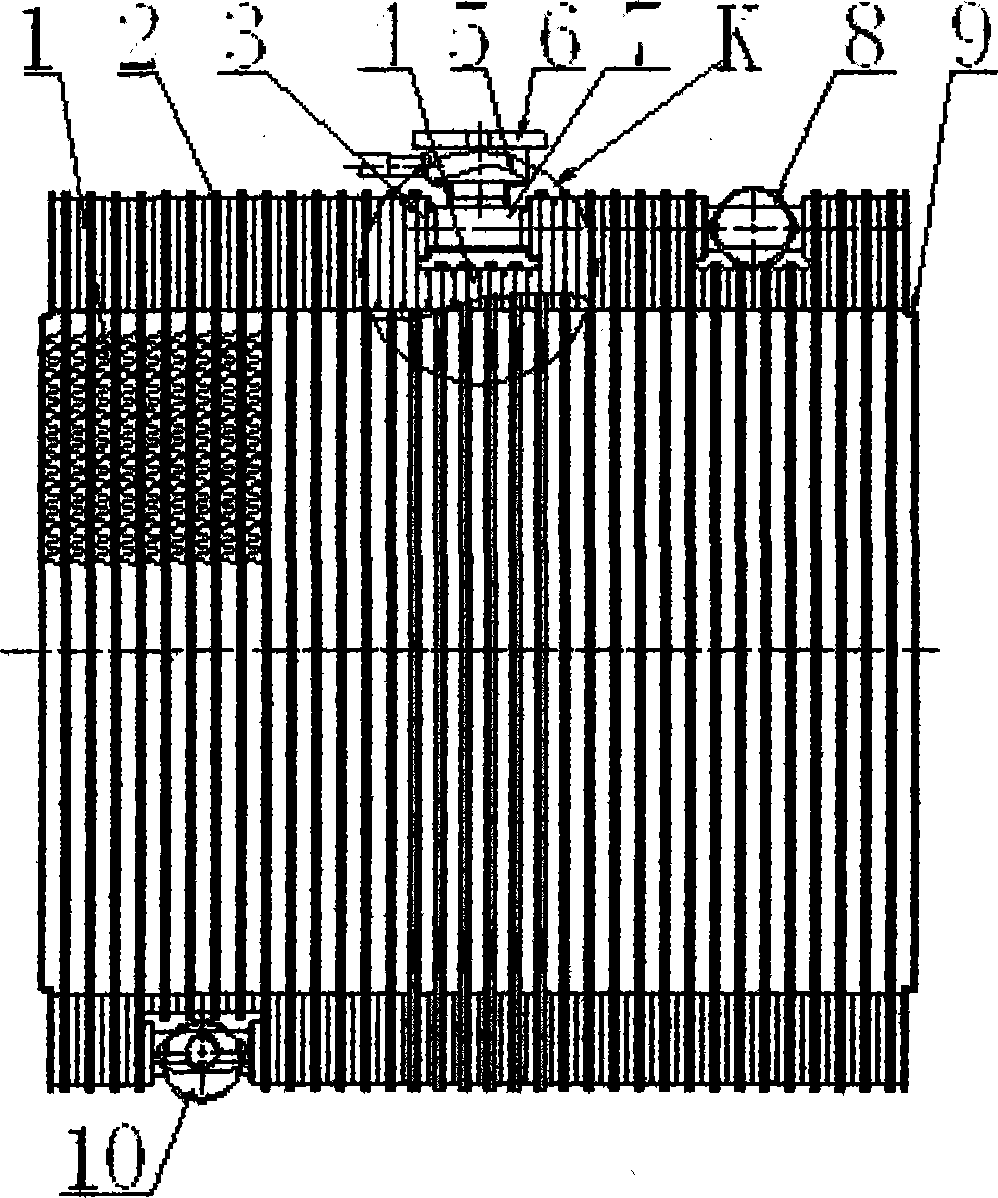

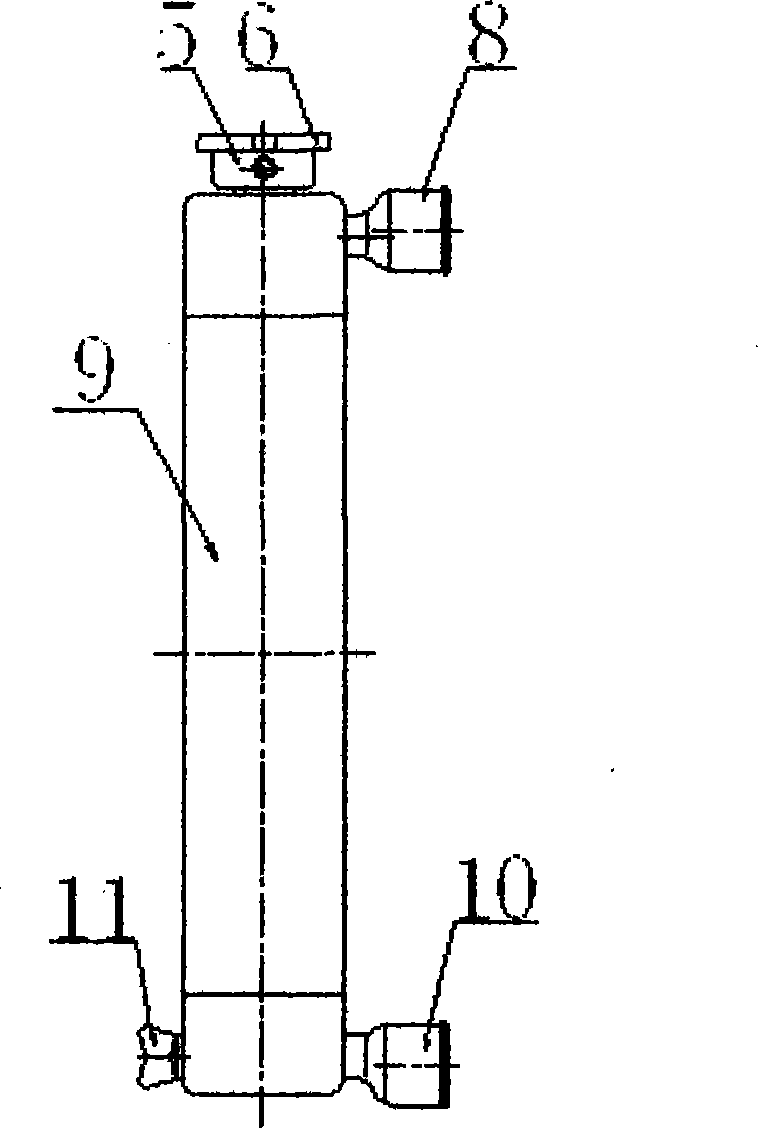

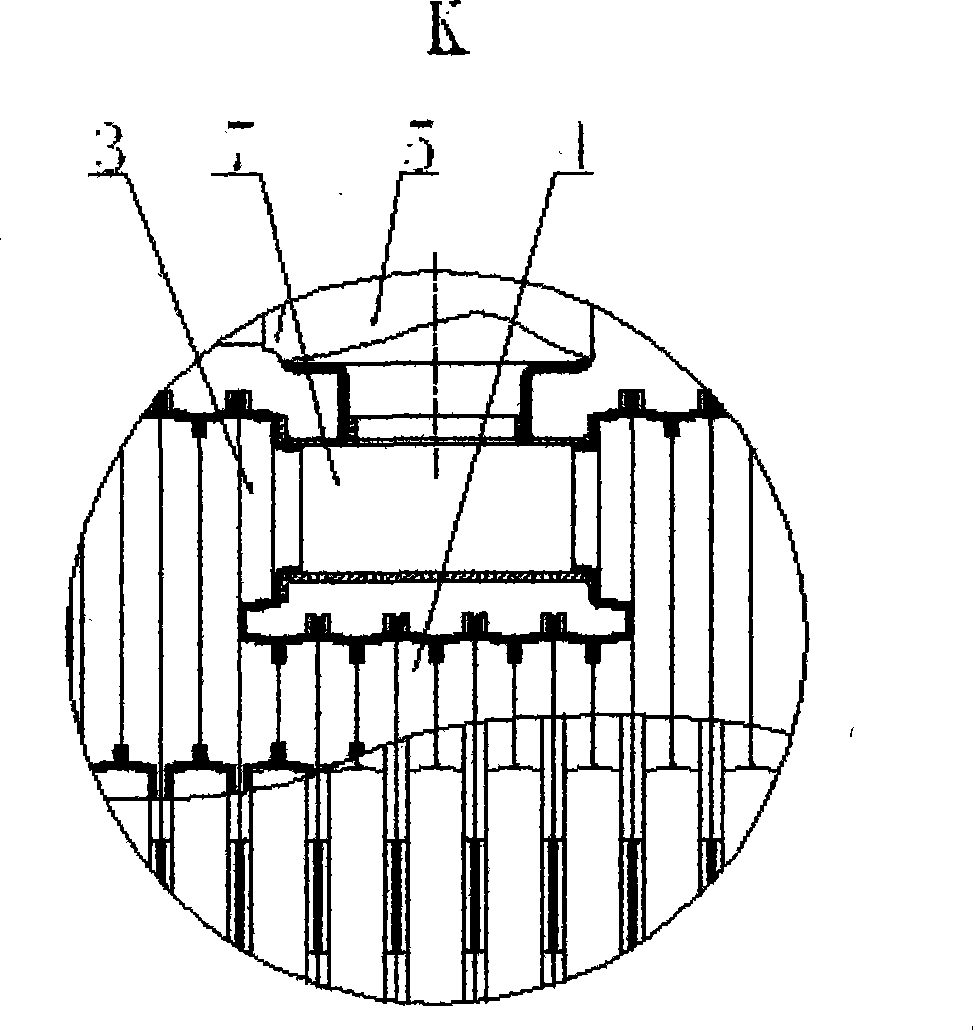

[0074] figure 1 It is the front view of the laminated car radiator according to the present invention. Ordinary laminations (2), small hole laminations (4), transitional laminations (3), heat dissipation strips (1), connecting pipes (7), water inlets (5), water inlet pipes (8), water outlet pipes (10 ), the side plate (9) is brazed in sequence, and the radiator cover (6) and figure 2 Drain valve (11) in.

[0075] Figure 4 It is the front view after the frame (13) is installed on the laminated car radiator according to the present invention, a rubber sheet (12) is added between the radiator and the frame (13), and it is fastened by a bolt assembly (14).

[0076] Figure 12 In the illustrated embodiment, a common lamination assembly is shown in Figure 10 The distribution and state of the inner rib bosses on the laminated parts after A-A is cut.

[0077] Figure 13 In the illustrated embodiment, a common lamination assembly is shown in Figure 10 After the B-B part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com