Concentric retaining sleeve of torsional specimen

A clamping sleeve and sample clamp technology, applied in the mechanical field, can solve the problems of difficult clamping of samples, affecting test accuracy, difficult operation, etc., and achieve the effect of improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

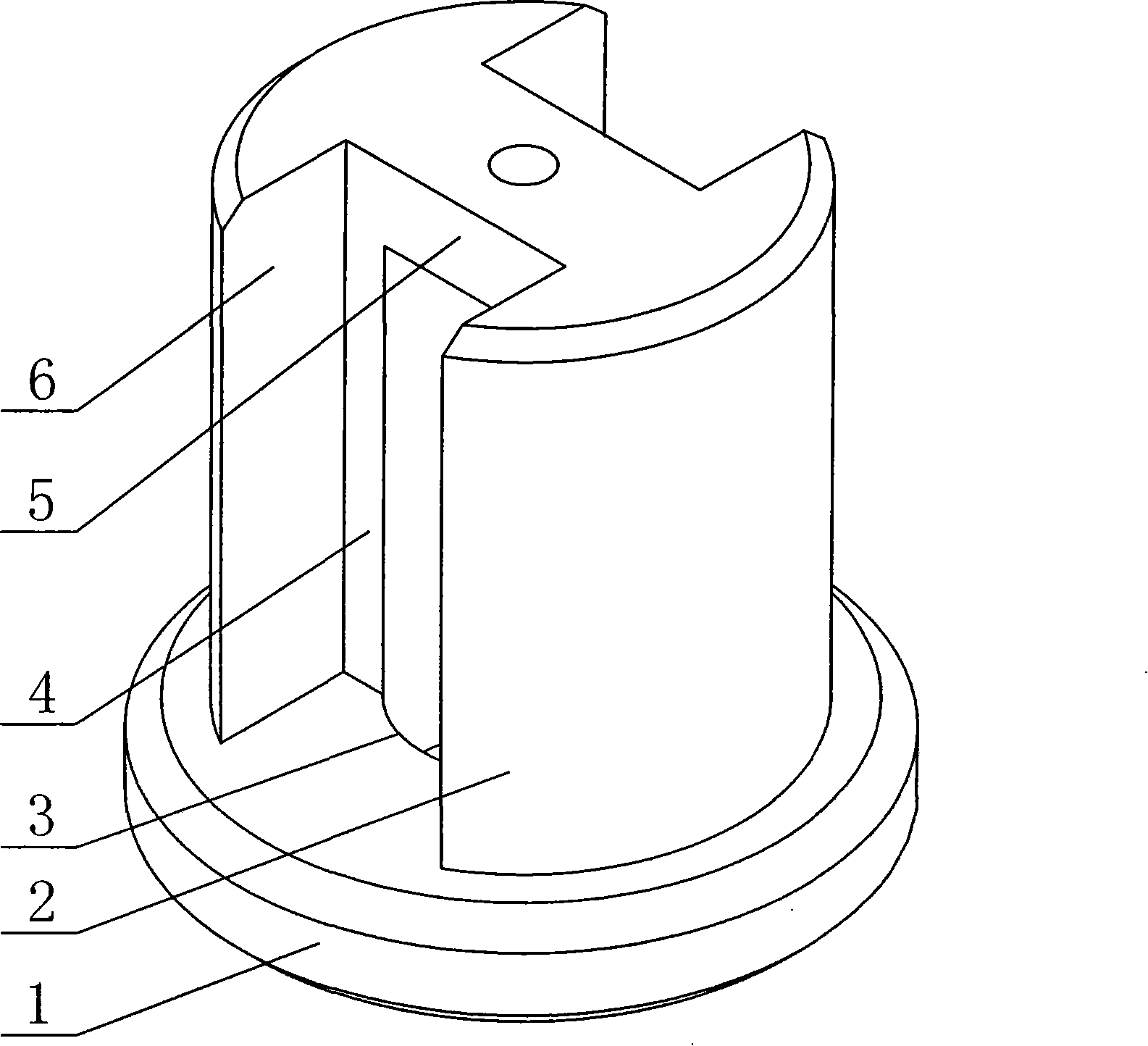

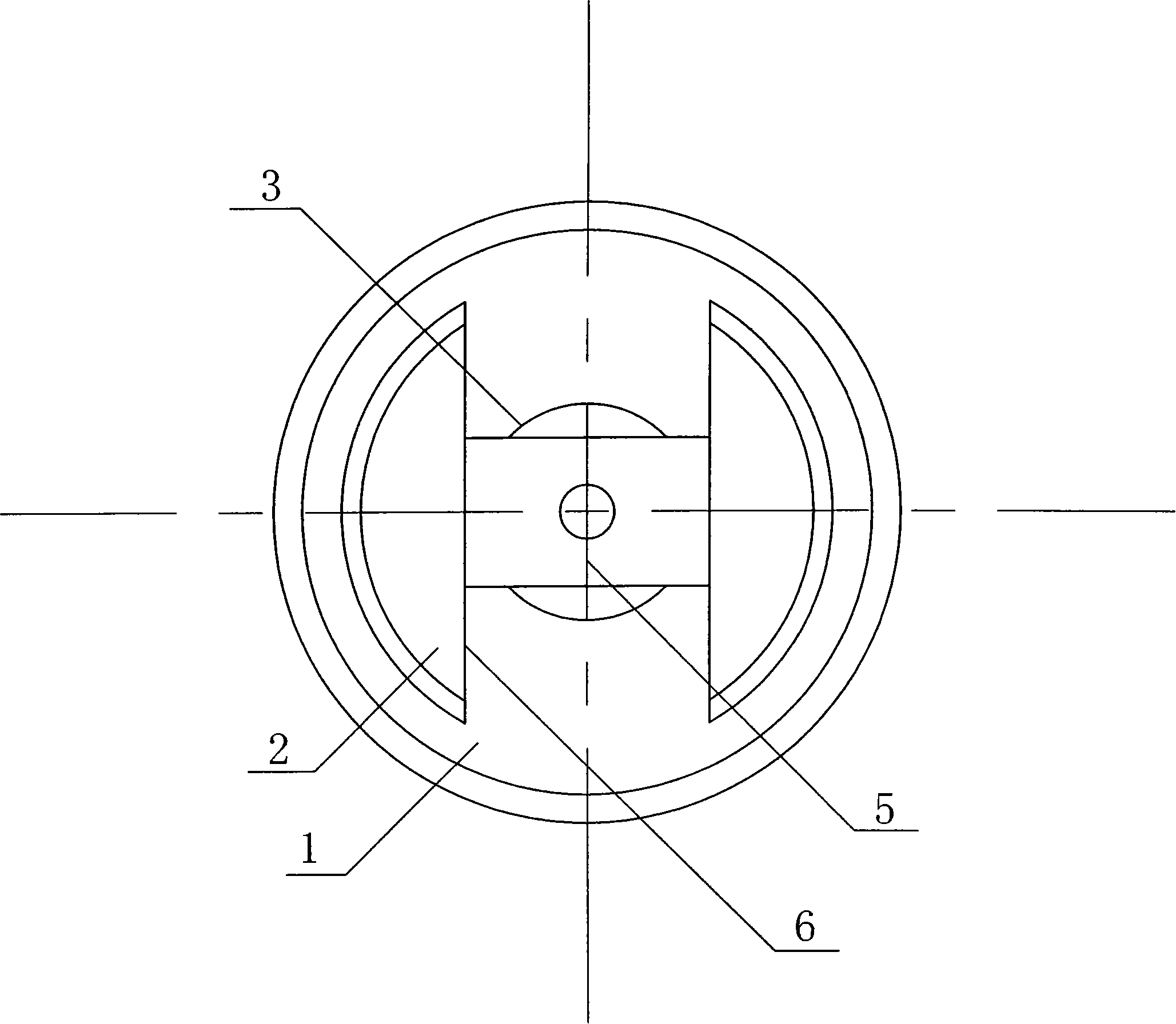

[0022] As a concentric clamping sleeve for torsion specimens, see figure 1 , including a base 1, a positioning wall 2, the outside of the positioning wall 2 is cylindrical, the positioning wall 2 is fixed on the base 1, the outer diameter of the positioning wall is smaller than the outer diameter of the base, and steps are formed on the edge of the base. The positioning wall 2 is two semicircular shapes whose end faces are connected together, and what connects the two end faces is the sample clamping section limiter 5 , and the plane of the base 1 is perpendicular to the positioning wall 2 . The processing of the positioning wall 2: one is to process the concentric positioning circular hole 3 on the original cylindrical body through the center of the base 1; . See also figure 2 , the arc-shaped inner wall in the middle section of the positioning wall 2 and the briquetting block limiting wall 4 are naturally formed by processing, which play the role of ensuring the concentr...

Embodiment 2

[0028] The overall structure is the same as that of Example 1. The limit stopper 5 of the sample clamping section connects the end faces of the two positioning walls 2 and is in the shape of a circular platform. It is formed by milling out two sealed rectangular grooves. At this time, the groove bottom of the rectangular groove is made of the square hole formed here by the concentric positioning circle 3 and the briquetting stop wall 4.

Embodiment 3

[0030] General structure is with embodiment 1,

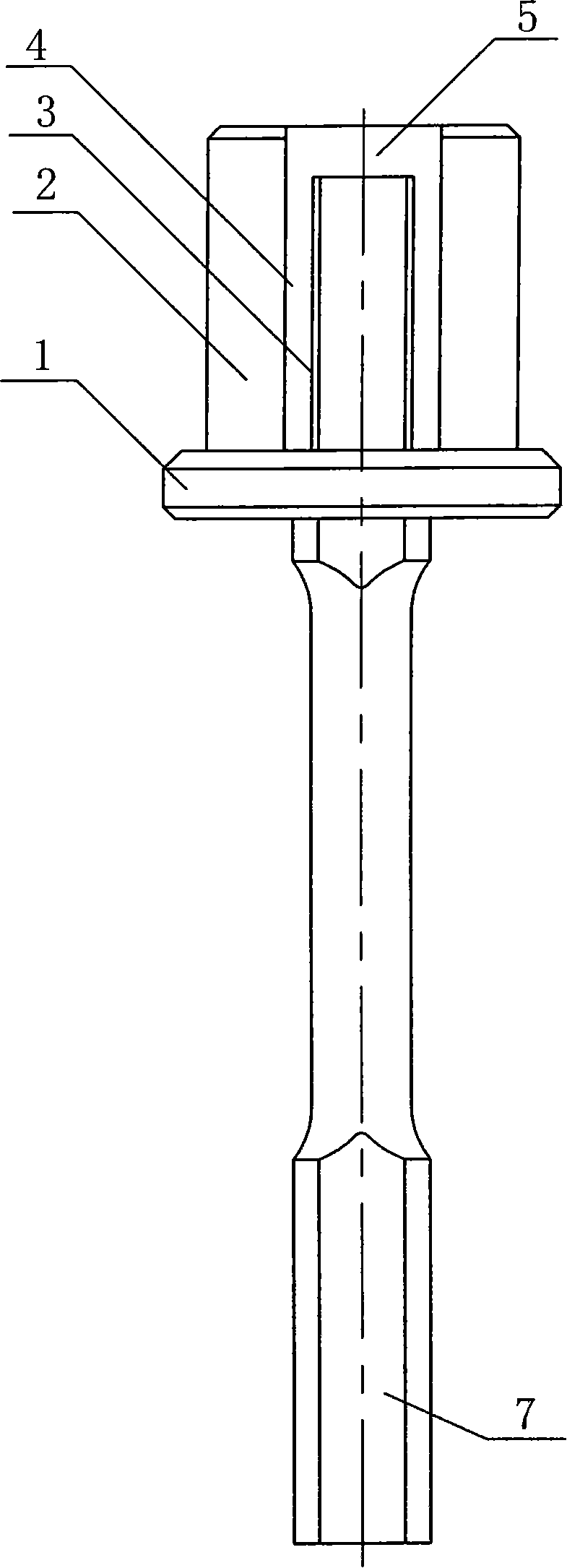

[0031] The concentric positioning circle 3, the diameter of its circular hole is based on the diameter of the sample clamping section 7, which is the dynamic fit tolerance, see image 3 . The outer circle of the positioning wall 2 corresponds to the size of the circular groove 10 on the chuck 9 of the torsion testing machine, which is a dynamic fit tolerance, see Figure 5 , after the clamping set is inserted into the chuck 9, the compression screw 12 is tightened so that the pressure block 8 is in accurate contact with the clamping surface of the sample, see Figure 4 , The sample clamping is accurate and firm, ensuring that the torsion sample is clamped reliably during the torsion process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com