Method for determining clothes weight in laundry machine and laundry machine implementing the same method

A technology of clothes weight and washing machine, applied in the field of washing machines, can solve the problems of increasing cost, reducing measurement accuracy, increasing workload, etc., and achieves the effects of easy assembly, simple structure and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

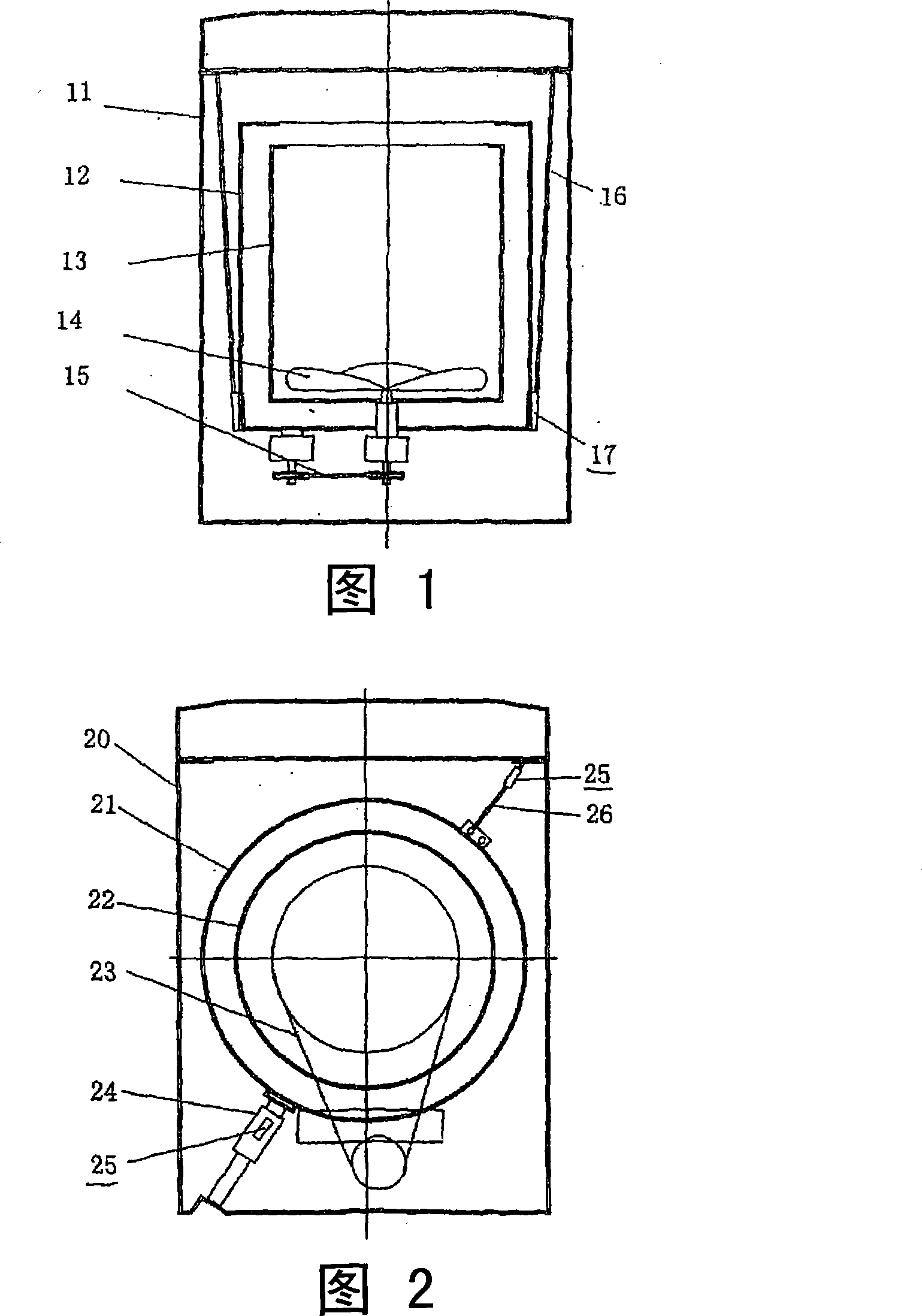

Embodiment 1

[0063] Use a water level sensing device (otherwise known as a water meter).

[0064] A water quantity sensing device is provided on the water inlet channel of the washing machine and a fixed water level L that can completely soak the clothes is provided.

[0065] In the central processing unit of the washing machine control device, an identification program for identifying the water absorption rate of clothes of different materials and an identification program for identifying the relationship of "water injection amount-clothes weight" are set.

[0066] The water absorption rate A is the amount of water absorbed by the unit weight of clothes of different materials determined by experiments when they are completely wet. In the above recognition procedure for recognizing the water absorption rate of the clothes, a selection switch (address) for manipulating different materials of the clothes is provided on the operation panel of the washing machine. If the user makes a definite...

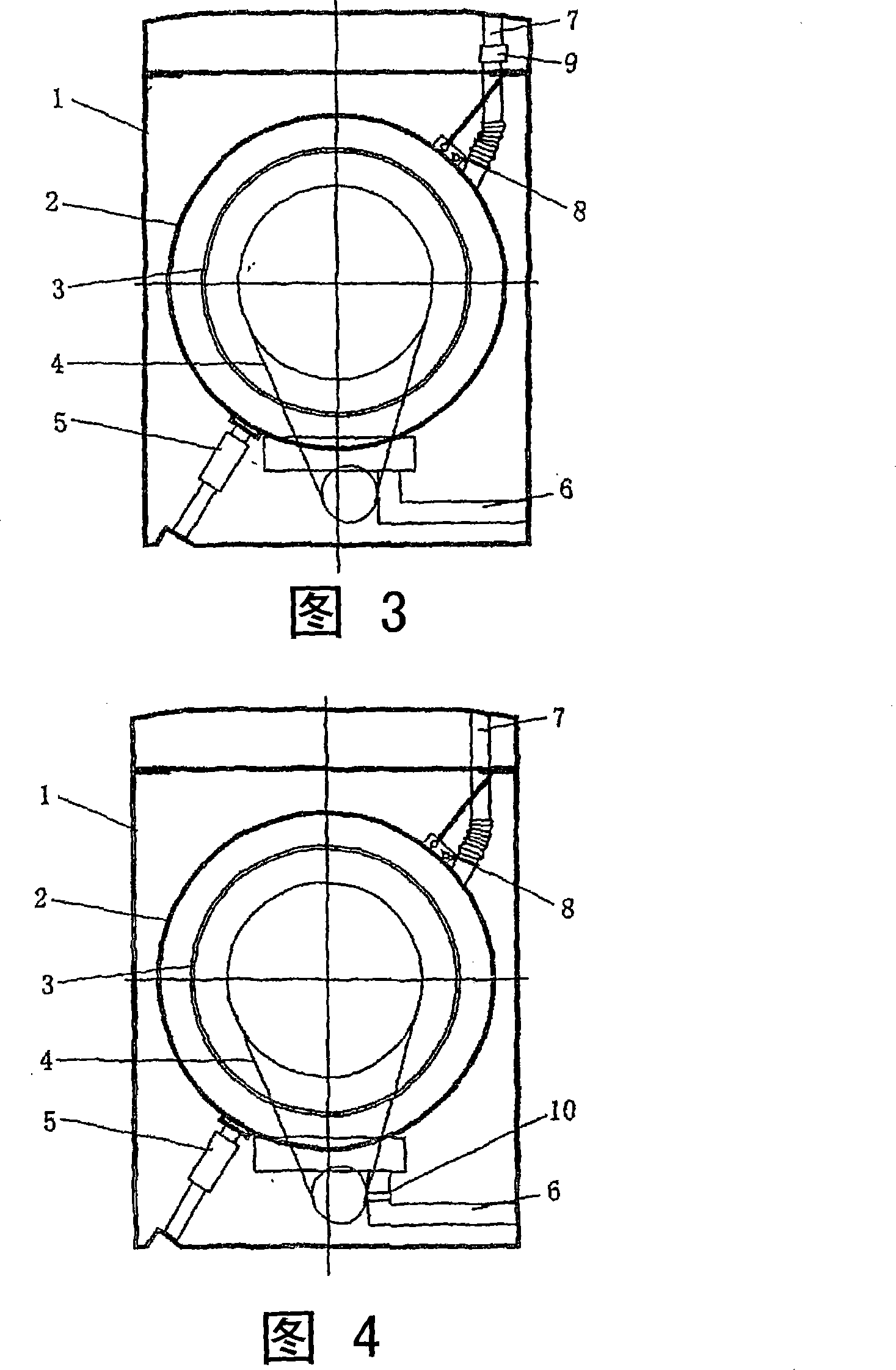

Embodiment 2

[0084] A pressure sensing device is arranged on the drain channel of the washing machine. Furthermore, a water level L1 is provided which activates the pressure sensor and is below the lowest position of the drum. At the above water level L1, the laundry in the drum will not be wetted by the water in the washing machine. At this time, the amount of water injected is W. In addition, a wetting water level L2 is set, wherein the clothes can be completely wetted by water. In this embodiment, the wetting water level L2 is measured by a pressure sensing device (not shown in FIG. 4 ) arranged on the water inlet channel.

[0085] In the central processing unit of the washing machine control device, an identification program for identifying the water absorption rate of different clothes, a corresponding identification program for identifying the relationship of "water injection amount-clothes weight" and a calculation program for water injection amount = time * water flow rate are se...

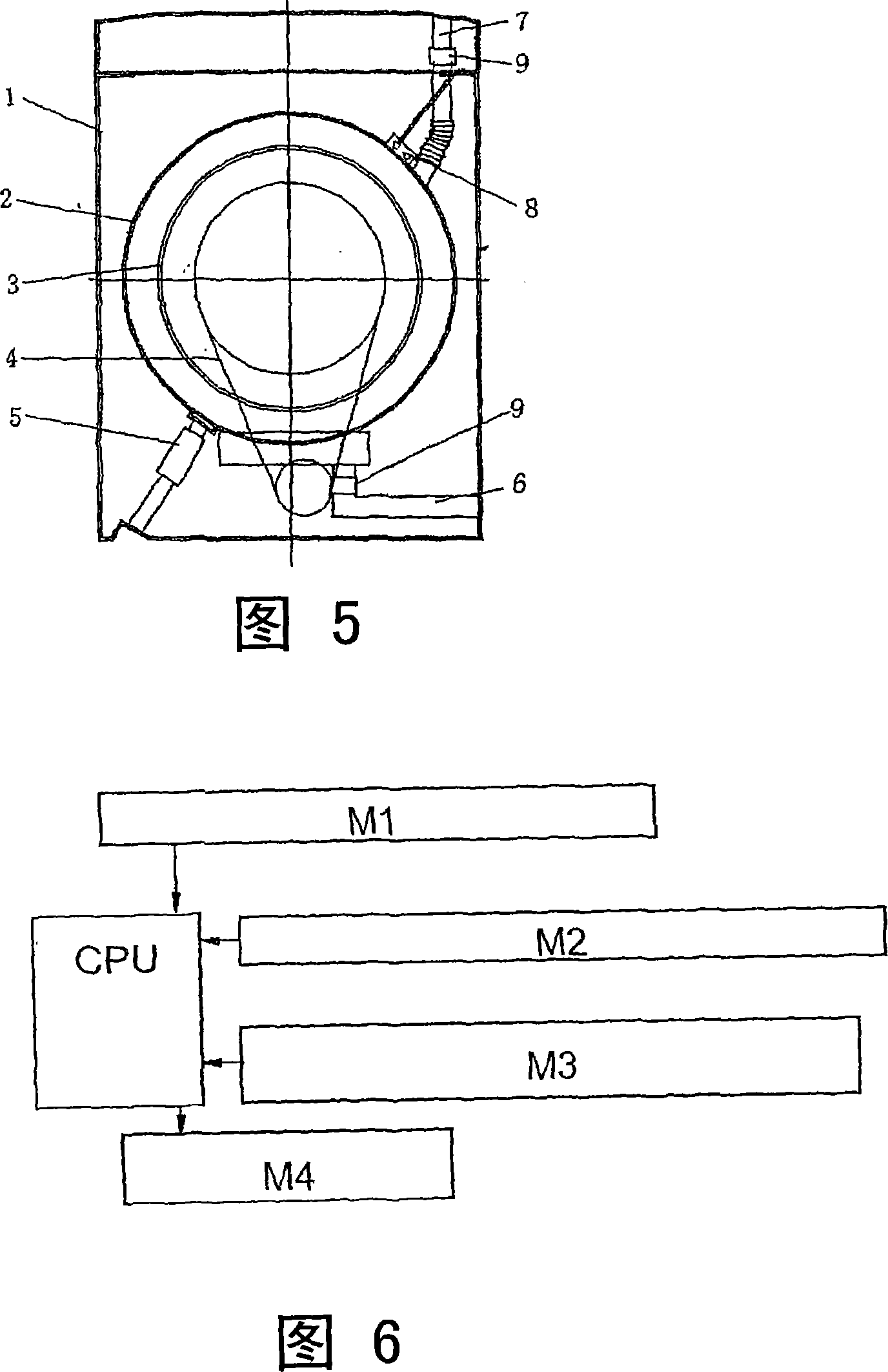

Embodiment 3

[0098] A water volume sensing device is provided on the water inlet channel of the washing machine and a fixed wet water level L which can completely wet the clothes is provided. In an embodiment, the wetting water level L is measured by a pressure sensing device (not shown in FIG. 3 ) arranged on the water inlet channel.

[0099] An identification program for identifying the water absorption rate of clothing of different materials and a laundry weight calculation program are set in the central processing unit of the washing machine control device.

[0100] The water absorption rate A is the amount of water absorbed by cloth of different materials per unit weight determined through experiments when it is completely wet. In the identification program for identifying the water absorption rate of the clothes, a selection switch (address) for operating different materials of the clothes is set on the operation panel of the washing machine. When the user selects the selection swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com