Anti-splash device of conical dissolvers

A dissolver and anti-splash technology, which is applied in the direction of dissolution, dissolution, chemical instruments and methods, etc., can solve the problems of superficial not permanent, device paralysis, loss of sealing and water vapor prevention, etc., to achieve equipment efficiency and avoid Moisture, overcome the effect of splashing water droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

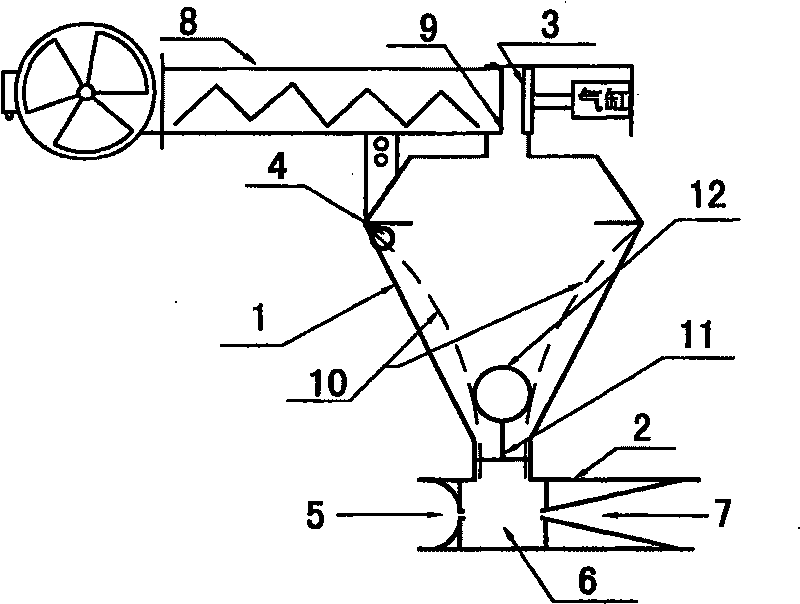

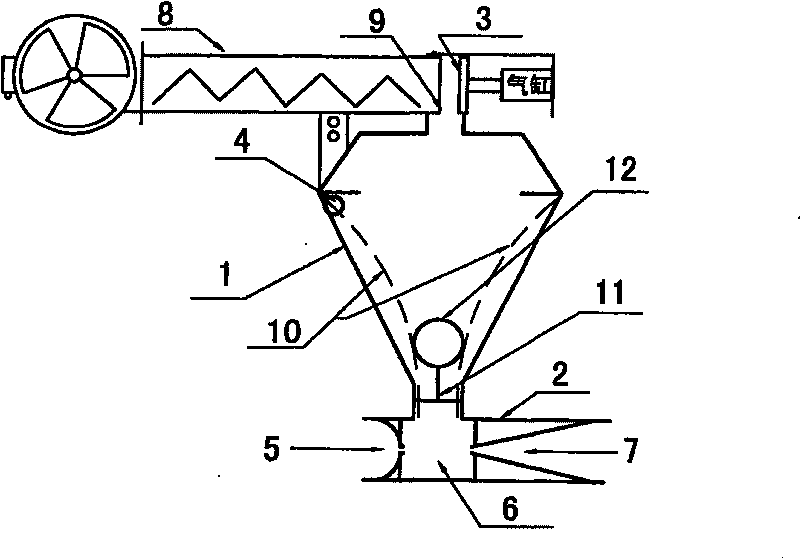

[0018] Now in conjunction with accompanying drawing, the present invention will be further described

[0019] An anti-splash device for a conical dissolver, which is composed of a conical dissolver, a water injector 2, a screw powder conveying device 8 and a water inlet pipe 4; the conical dissolver is a conical hollow vertical body 1 installed upside down, The small opening faces down and is sealed and welded around the upward opening of the water ejector suction chamber 6 through the outlet pipe; the water ejector is composed of a nozzle 5 at one end, a suction chamber 6 in the middle, and a diffuser pipe 7 at the other end to seal the pipe; The upward opening of the cone is facing the powder outlet 9 of the screw powder delivery device 8, and the powder outlet has a waterproof gate 3 that can be pushed open when feeding; on the outer edge of the large mouth of the cone, a hole is introduced parallel to the wall surface of the cone to form a hole. The water inlet pipe 4 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com