Formula of modifier for road engineering fill

A modifier and formula technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of large shrinkage cracking and slow strength formation, and achieve shrinkage cracking reduction, good social benefits and environmental protection benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

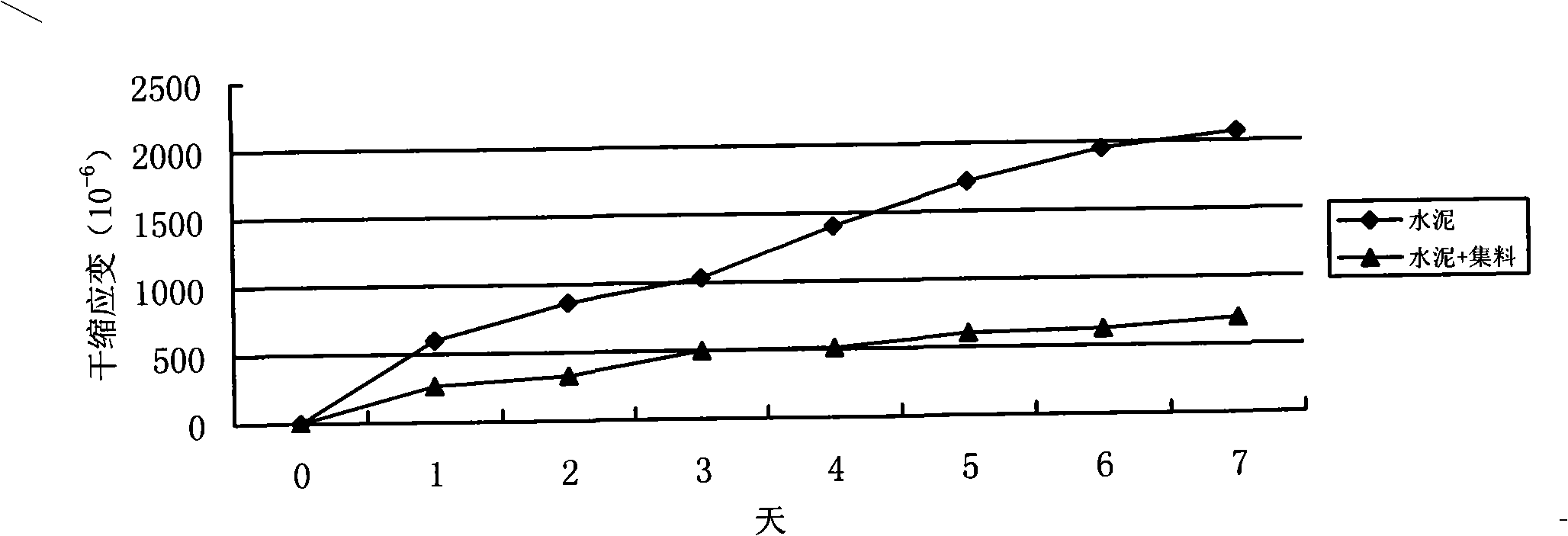

Problems solved by technology

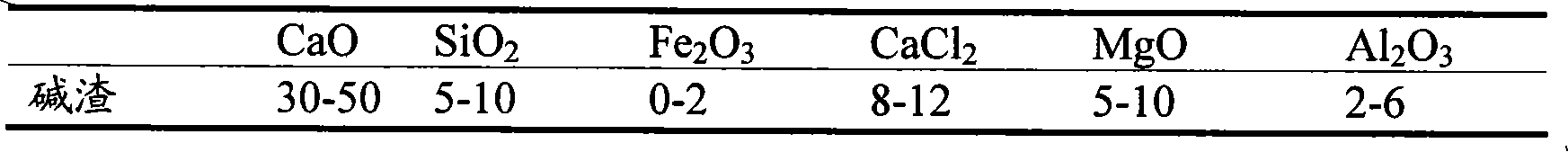

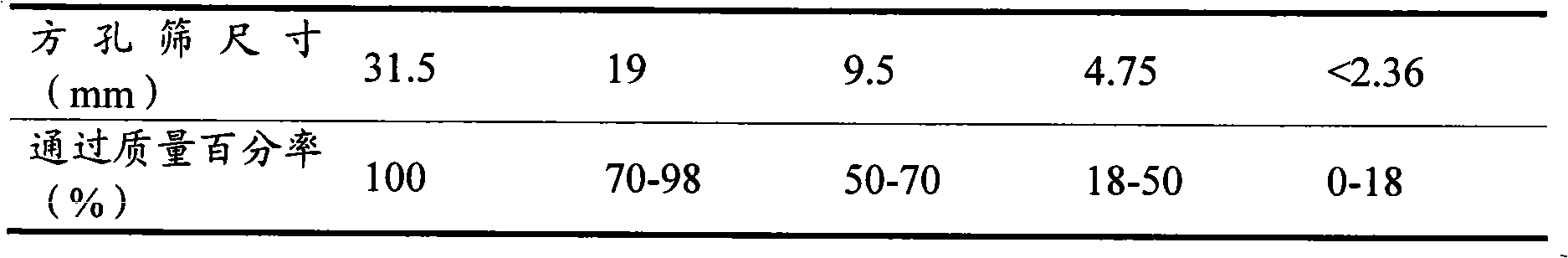

Method used

Image

Examples

Embodiment 1

[0024] The content of cement is 16%, the content of alkali slag is 18%, and the content of waste concrete particles is 66%. Add 25% into the non-applicable soil, add water and mix to the optimum moisture content, mix evenly, and compact when required. The 7-day unconfined compressive strength and bearing ratio reached 0.41Mpa and 127% respectively; while the 7-day unconfined compressive strength and bearing ratio of cement-modified soil with the same cement content (4% cement) 0.20Mpa and 60%; the 7-day unconfined compressive strength and load-carrying ratio of lime-modified soil with 4% lime are less than 0.08Mpa and 30% respectively.

Embodiment 2

[0026] The cement content is 16%, the alkali slag content is 8%, and the waste concrete particle content is 76%. Add 25% of the mixing amount to the non-applicable soil, add water and mix to the optimum moisture content, mix evenly, and compact when required. The 7-day unconfined compressive strength and bearing ratio reached 0.35Mpa and 110% respectively; while the 7-day unconfined compressive strength and bearing ratio of cement-modified soil with the same cement content (4% cement) 0.20Mpa and 60%; the 7-day unconfined compressive strength and load-carrying ratio of lime-modified soil with 4% lime are less than 0.08Mpa and 30% respectively.

Embodiment 3

[0028] The content of cement is 10%, the content of alkali slag is 10%, and the content of waste concrete particles is 80%. Add 25% of the mixing amount to the non-applicable soil, add water and mix to the optimum moisture content, mix evenly, and compact when required. The 7-day unconfined compressive strength and bearing ratio reached 0.28Mpa and 98% respectively; while the 7-day unconfined compressive strength and bearing ratio of cement-modified soil with the same cement content (2.5% cement) 0.14Mpa and 40%; the 7-day unconfined compressive strength and bearing ratio of lime-modified soil with 2.5% lime are less than 0.05Mpa and 25% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com