High-water-repellency and high-slidability coating member, fabrication method for same, and high-water-repellency and high-slidability product using same

A manufacturing method and water-repellent technology, which can be used in coatings, devices for coating liquids on surfaces, special surfaces, etc., to solve problems such as practical limitations, insufficient wear resistance, and difficulty in coating, and to expand applications. range, the effect of excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] Hereinafter, the present invention will be specifically described by way of examples, but the present invention is not limited to these examples.

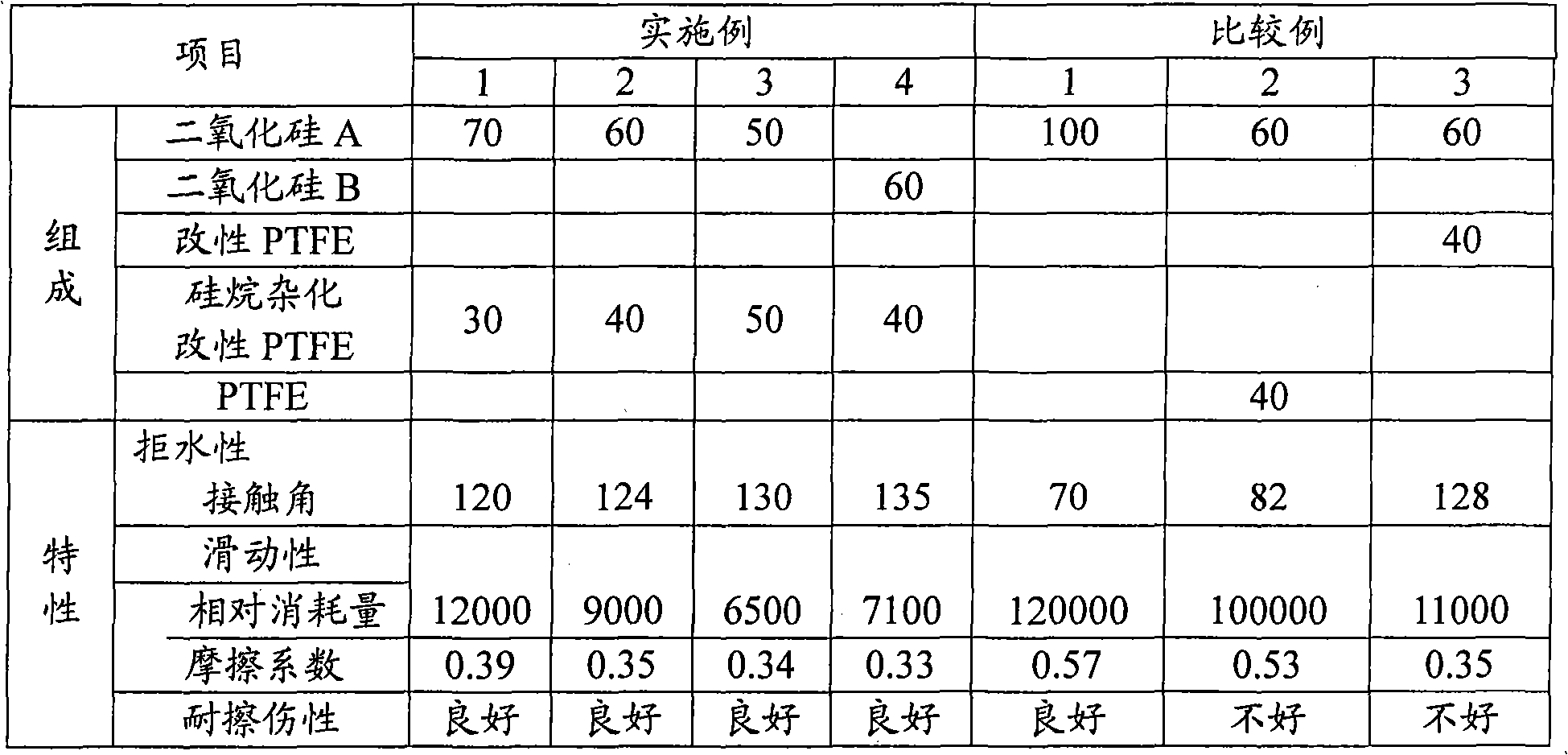

[0059] Table 1 Compounding amount: parts by weight

[0060]

[0061] Silica A: 50wt% isopropanol solution of silica sol adjusted by hydrolysis of methyl silicate with acetic acid

[0062] Silica B: 50 wt% ethanol solution of silica gel adjusted by hydrolysis of ethyl silicate with hydrochloric acid

[0063] Slidability: relative wear (×10 -8 mm 3 / Nm)

[0064] In Examples 1 to 4 and Comparative Examples 1 to 3, an aluminum plate was used as a base material to produce a water-repellent and highly slidable coated part.

[0065] (1) Production of components

[0066] On the aluminum surface with a thickness of 2 mm, a 0.001% by weight triethylmethoxysilane ethanol solution was sprayed, and then dried with an infrared lamp, and this operation was repeated three times.

[0067] Then, a solution having the composition show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com