PHC pipe-pile pile-anchor combined support water stop construction method

A PHC pipe pile and construction method technology, applied in excavation, sheet pile wall, foundation structure engineering, etc., can solve problems such as pipeline damage, unsafe underground operation, building settlement or cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

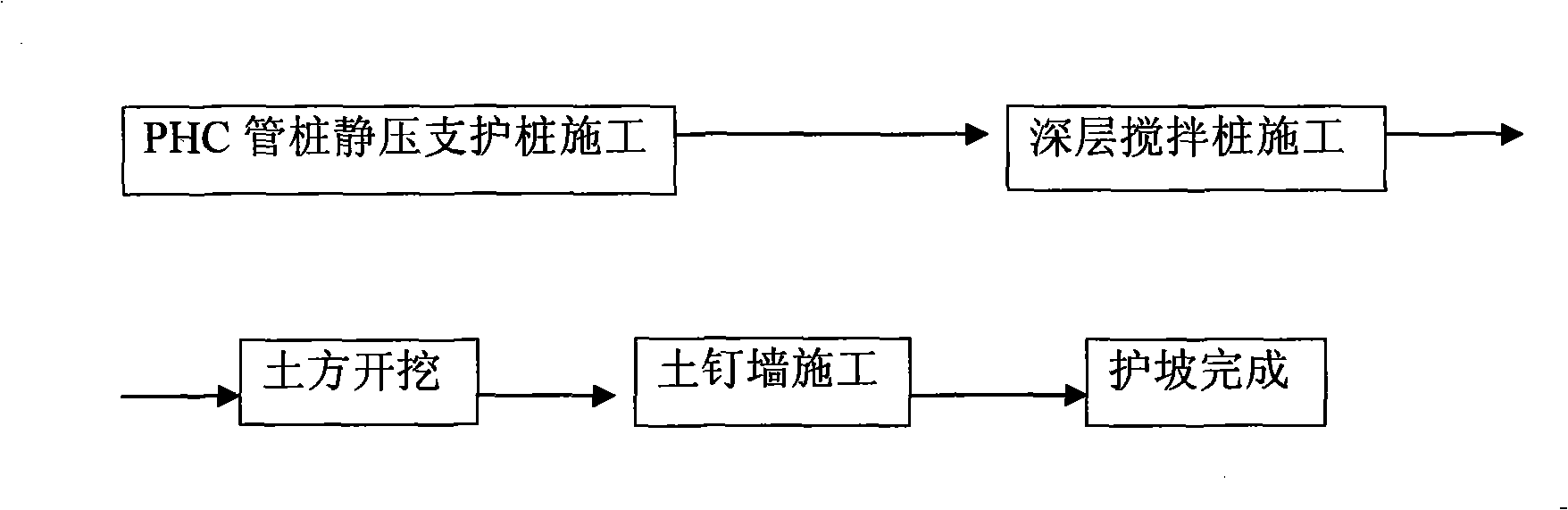

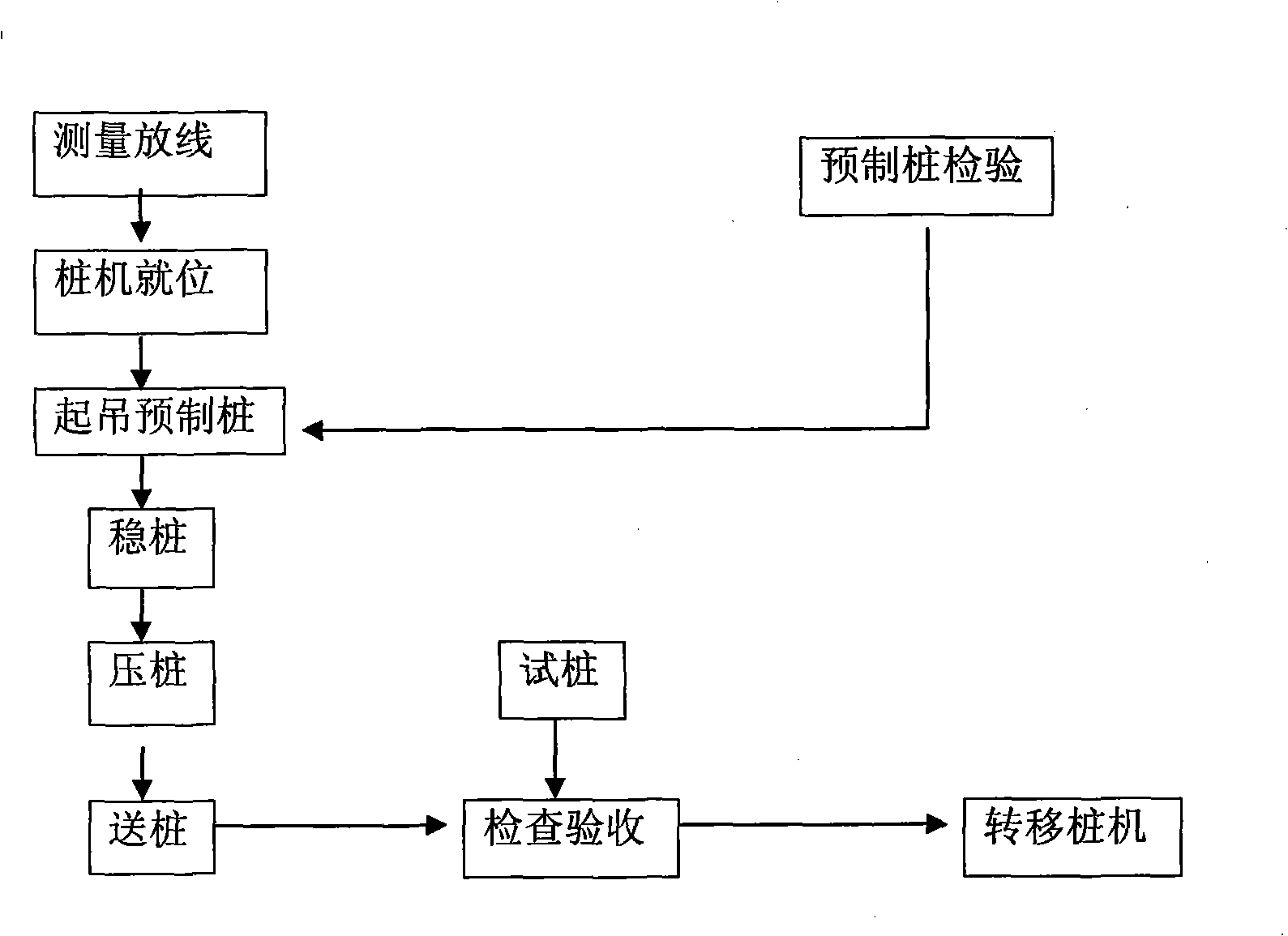

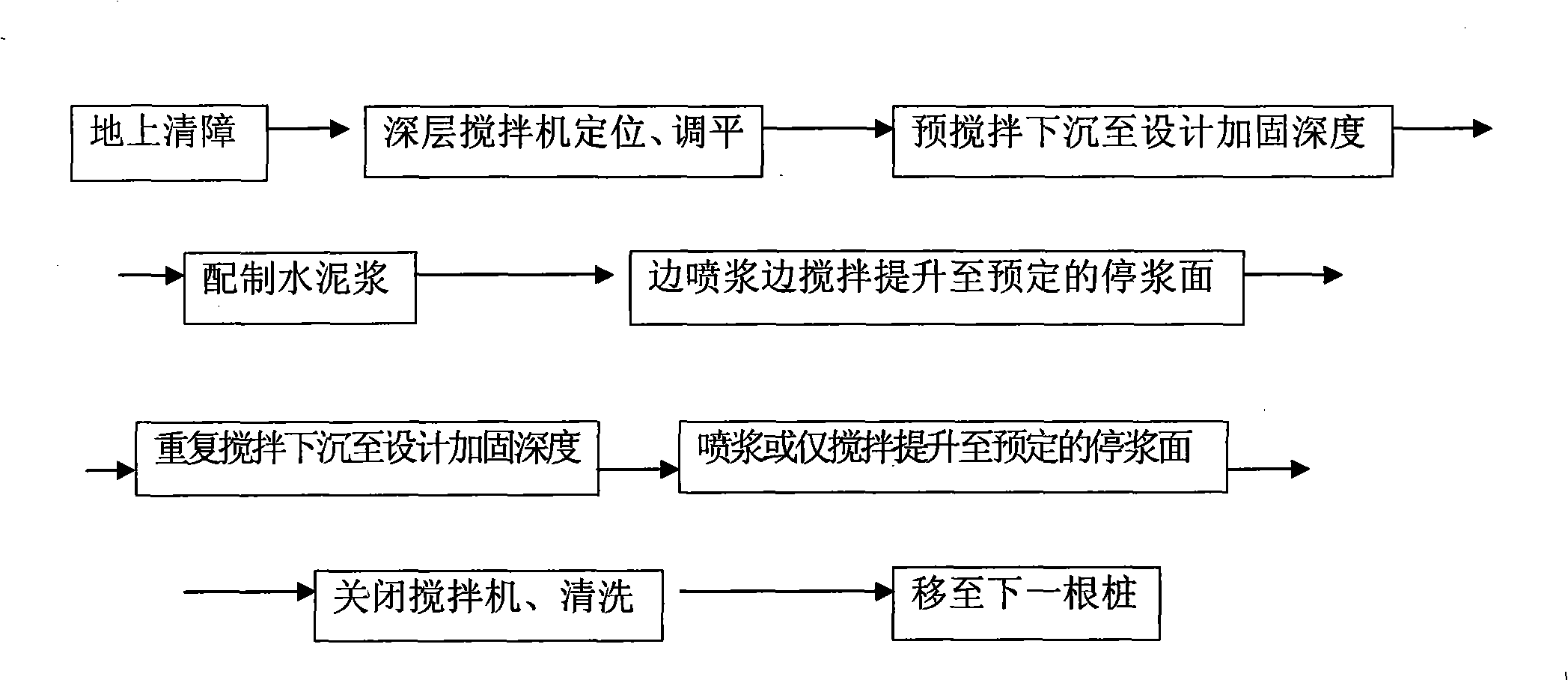

[0008] The present invention will be described in detail below in conjunction with the process flow diagram. Depend on figure 1 , figure 2 , image 3 , Figure 4 Provide, construction method of the present invention is:

[0009] (1) at first prepare PHC pipe pile static pressure support pile, method is,

[0010] 1. Measure and set out the line. Set up control pile pre-leveling points near the piling construction area, not less than 2. The position is based on the principle that it will not be affected by piling (outside 40m from the operation site). The axis control should be set at a distance from the outer wall pile. 5-10m to control the axis and elevation of the pile foundation;

[0011] 2. Put the pile driver in place, move the static pile driver to the top of the pile according to the pile driving sequence, and align it with the pile location, adjust the static pile driver to a level and stable position to ensure that no tilting and movement will occur during constr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com