Ultra-high layer combined wall dual structure architecture

A composite wall and super high-rise technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of vertical shear yielding mechanism of composite walls that have not been applied, and achieve high bearing capacity, concentrated damage, and good ductility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

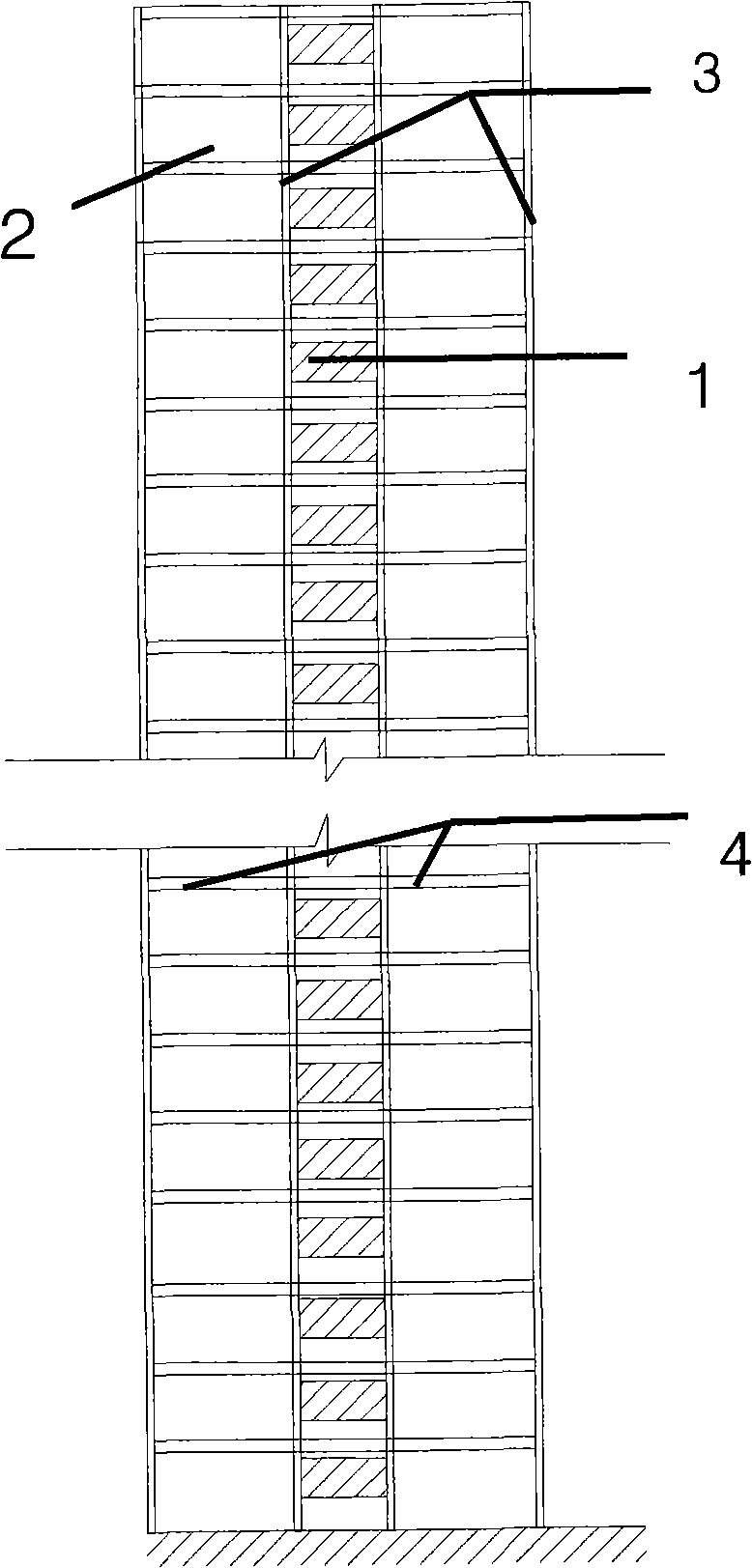

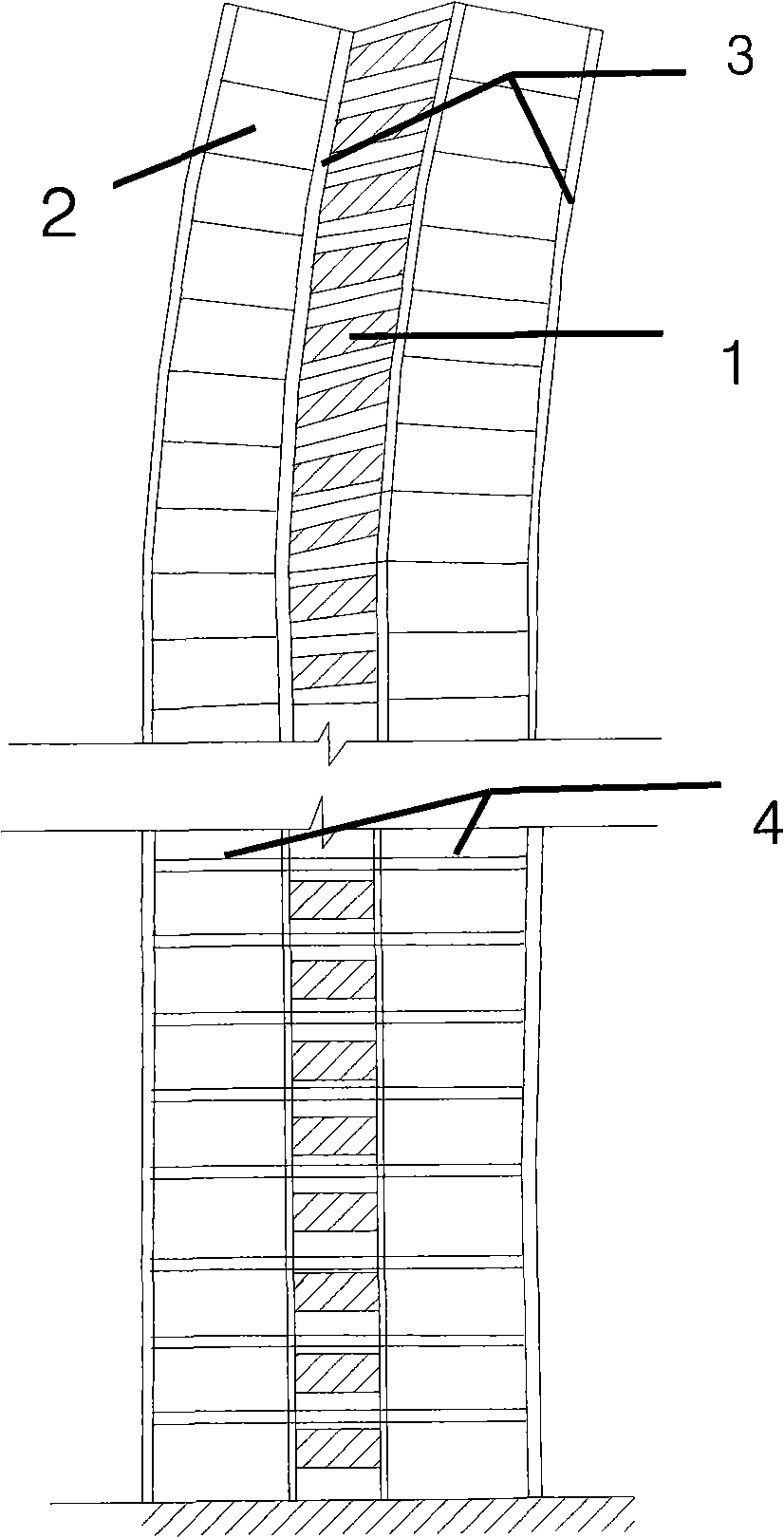

[0016] Embodiment 1: The super high-rise composite wall system of the present invention is made up of shear wall 1, composite steel plate wall 2, edge member 3 and steel frame beam 4, wherein, shear wall 1 adopts four-sided connection composite steel plate shear wall, composite steel plate Wall 2 adopts composite walls connected on both sides. Shear wall 1, which is the main anti-lateral force component of the structure, can use composite wall concrete slabs, which can be prefabricated or cast-in-situ. Concrete slabs. Controlling the thickness of the steel plates in the composite steel wall 2 and the thickness of the steel plates in the thick composite wall 1 makes the thin composite steel wall yield under large earthquakes while the steel plates in the composite wall 1 still maintain an elastic state. Edge member 3 can adopt steel column or SRC column. All edge members 3 are rigidly connected to the steel frame beams.

[0017] In order to verify the feasibility of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com