Method for measurement of printed circuit gold-plating layer porosity

A technology of printed circuit and measurement method, which is applied in the direction of measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., and can solve problems such as scratches, thin protective film, and difficulty in accurately calculating porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

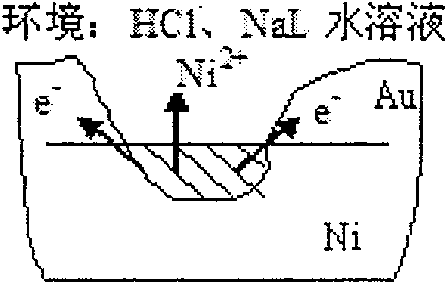

[0055] Add 100ml of deionized water into a 250ml volumetric flask, measure 11.77ml of 36% concentrated HCl, mix well, add 1.25g of NaCl, then add 0.50ml of penetrant with a concentration of 10%, and add deionized water to tick marks. Both HCl and NaCl were of analytical grade.

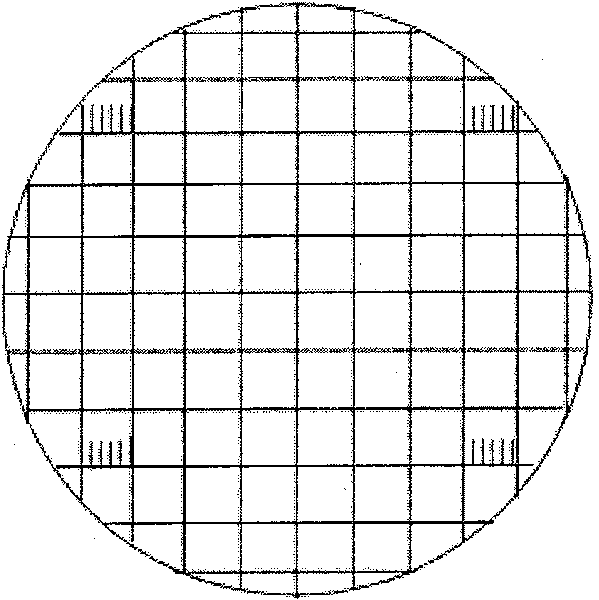

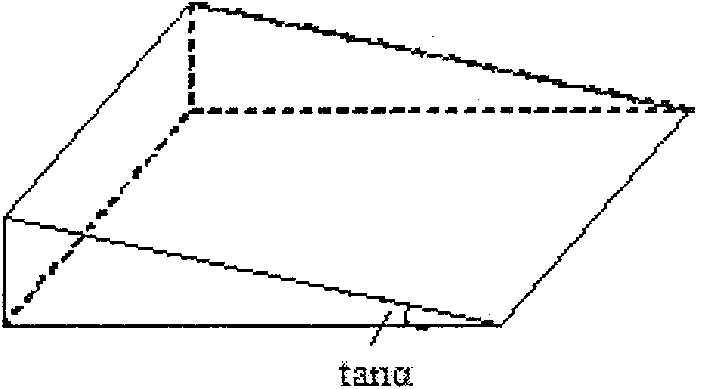

[0056] Taking the printed board (sample 1) that has undergone the electroplating nickel / gold plating process, the thickness of the Ni layer is measured to be 3.324 μm, and the thickness of the Au layer is 0.125 μm. Put the sample in the above-mentioned test solution at a temperature of 22°C for 5 minutes after the oil is removed, blot it dry with absorbent paper, and observe it under a 20X optical microscope. When observing, use a transparent square mesh with a line width of 0.1 mm and a spacing of 1 mm. The Gefferin negative film is installed under the eyepiece of the low power microscope. The inclined plane with an inclination angle of tanα between 0.15 and 0.25 is a inclined plane made of rubber or...

Embodiment 2

[0058] According to the method of Example 1, prepare 250 ml of test solution with hydrochloric acid concentration of 2.3%, sodium chloride concentration of 1.0%, and penetrant concentration of 0.05%.

[0059] Taking the printed board (sample 2) after electroplating nickel / thick gold plating process, the thickness of the Ni layer was measured to be 6.570 μm, and the thickness of the Au layer was 0.520 μm. Put sample 2 into the above-mentioned test solution at 21°C for 8 minutes after removing the oil, blot it dry with absorbent paper, and observe it under a 20X optical microscope. When observing, use a transparent square mesh with a line width of 0.1 mm and a spacing of 1 mm. The Gefferin film is installed under the eyepiece of the low-power microscope. The inclined plane with an inclination angle of tanα between 0.15 and 0.25 is a inclined plane made of rubber or wood with the same inclination angle of tanα. The final porosity calculated according to Table-1 is 0.3 / cm 2 .

Embodiment 3

[0061] According to the method of Example 1, 250 ml of test solutions with hydrochloric acid concentration of 2.5%, sodium chloride concentration of 1.5%, and penetrant concentration of 0.1% were prepared.

[0062] Taking the printed board (sample 3) subjected to the immersion soft nickel / immersion gold process, the thickness of the Ni layer was measured to be 1.248 μm, and the thickness of the Au layer was 0.070 μm. Put the sample 3 into the above-mentioned test solution at a temperature of 22°C for 5 minutes after removing the oil stains, blot it dry with absorbent paper, and observe it under a 20X optical microscope. When observing, use a transparent square mesh with a line width of 0.1 mm and a spacing of 1 mm. The Gefferin film is installed under the eyepiece of the low-power microscope. The inclined plane with the inclination angle tanα between 0.15 and 0.25 is a inclined plane with the same inclination angle tanα made of rubber or wood. The final porosity calculated acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com