Method for on-line regulating-correcting firedamp sensor for mining safety monitoring system

A safety monitoring system and gas sensor technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve the problems of gas false alarms, mine safety production hazards, and production operation effects, and prevent false alarms. , The calibration steps are simple, and the effect of shortening the blind area of the monitoring period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

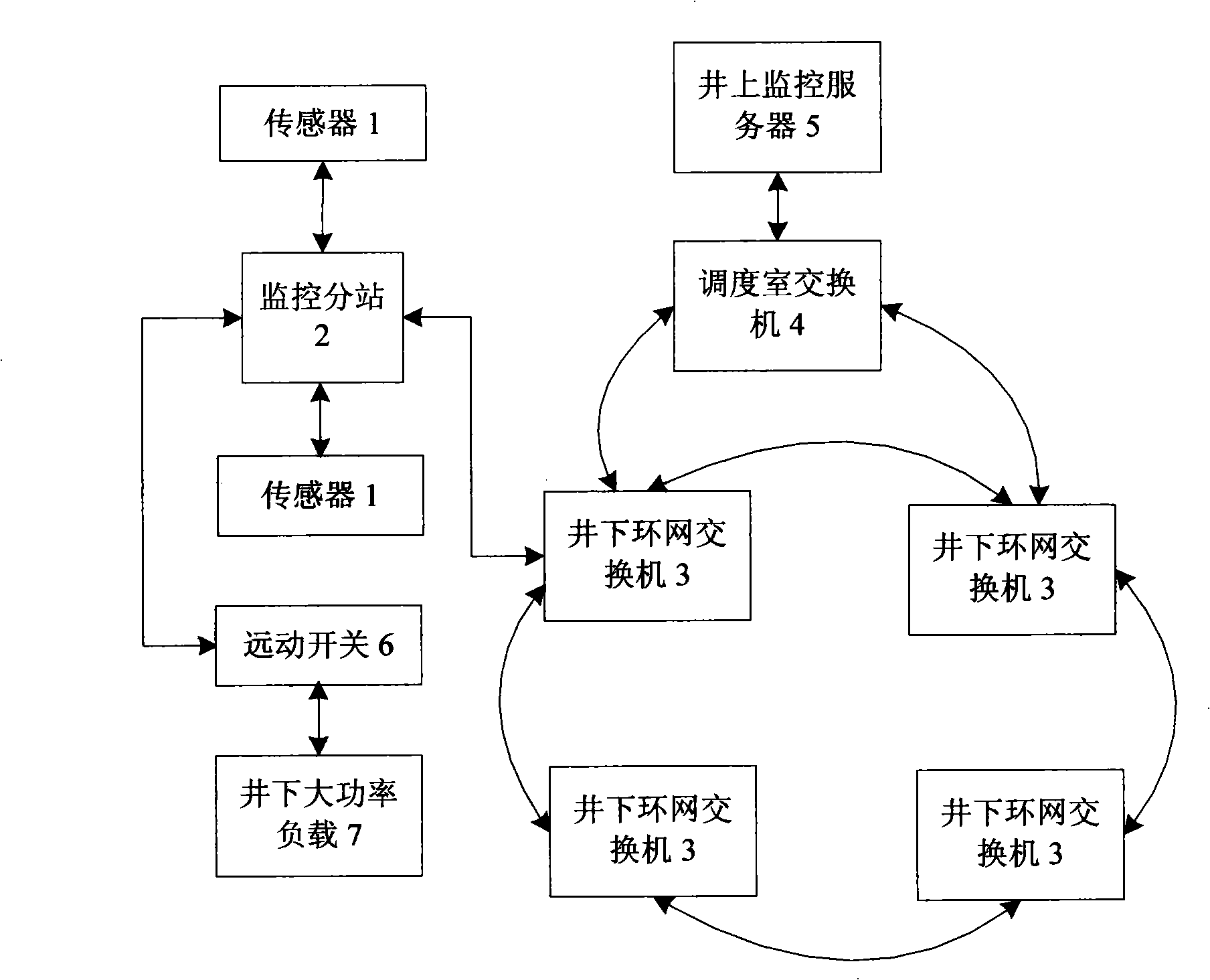

[0020] See figure 1 , the mine safety monitoring system of this embodiment includes: a plurality of gas sensors 1, at least one monitoring substation 2 connected to each gas sensor 1, a ring network composed of a plurality of underground ring network switches 3, and an underground ring network The control room switch 4 connected to the network switch 3, the well monitoring server 5 connected to the control room switch 4, the remote switch 6 used to control the power supply of the underground high-power load 7 connected to the monitoring substation 2; the monitoring substation 2 and The underground ring network switch 3 is connected. The downhole high-power load 7 is a media collector or the like. Monitoring substation 2 is an industrial control computer.

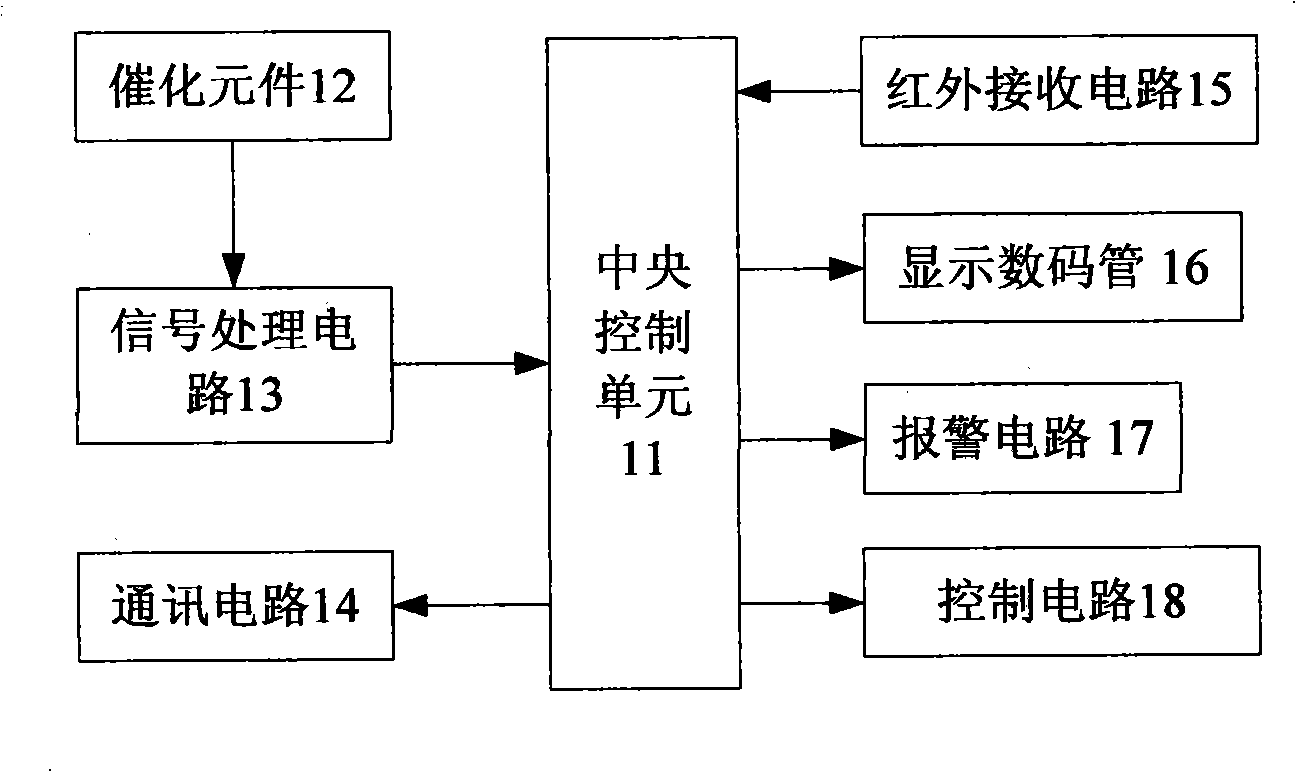

[0021] See figure 2 The gas sensor 1 includes: a remote controller, an infrared receiving circuit 15 matched with the remote controller, a central control unit 11 connected to the infrared receiving circuit 15, a catalyt...

Embodiment 2

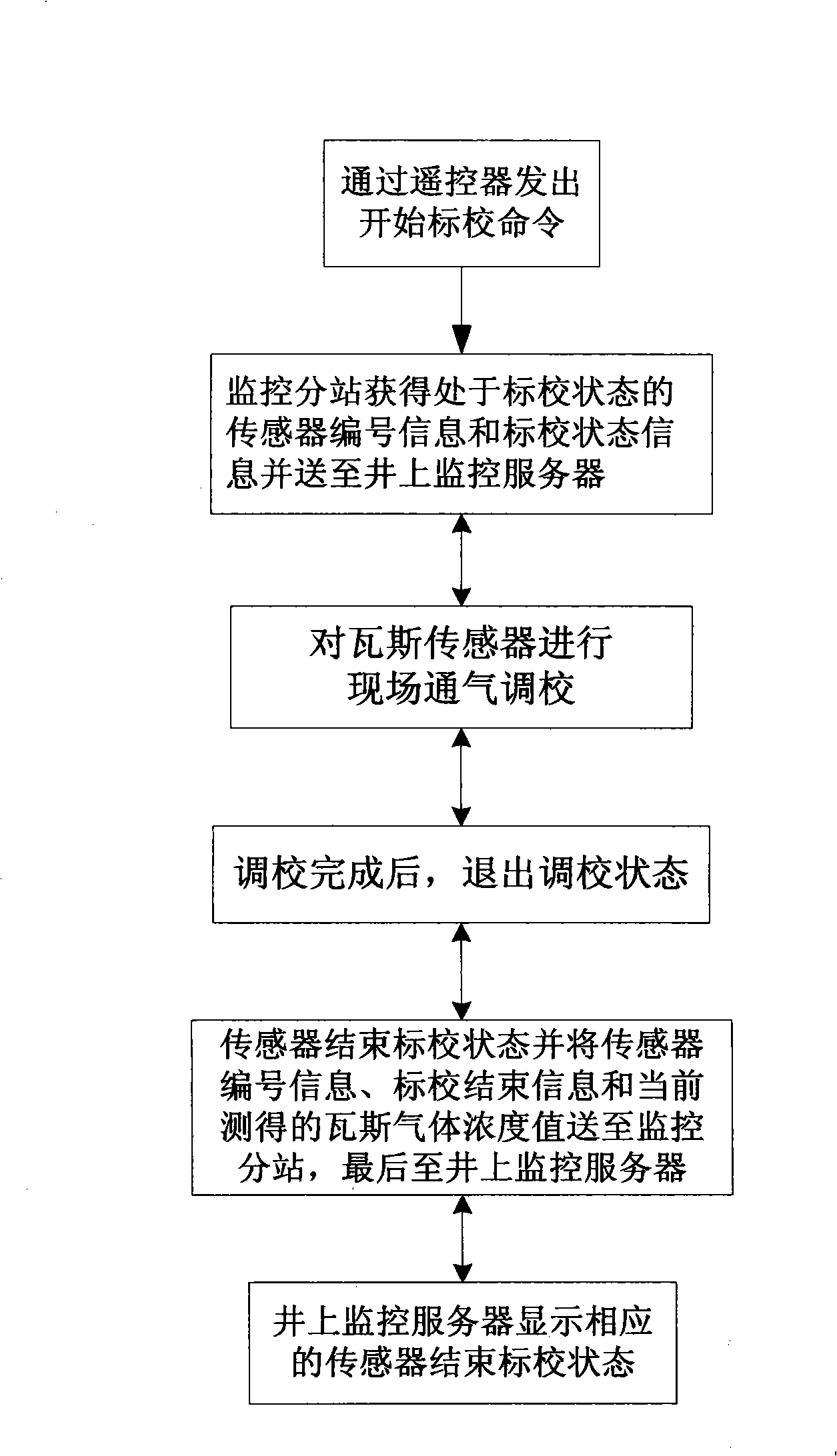

[0033] See figure 1 , 2 And 4, the online calibration method of the gas sensor of the mine safety monitoring system of the present embodiment, comprises the steps:

[0034] a. After the user sets a gas sensor 1 in the calibration state through the substation control keyboard of the monitoring substation 2 or the substation remote control, the monitoring substation 2 will send the sensor number information and calibration status information corresponding to the gas sensor 1 It is sent to the monitoring server 5 on the well through the communication network; the monitoring server 5 on the well shows that the gas sensor 1 is in the calibration state, and displays the sensor number; the display digital tube 16 of the gas sensor 1 prompts that it is in the calibration state.

[0035]b. Carry out on-site ventilation calibration for the gas sensor 1, that is: the user sends a sensor calibration command to the infrared receiving circuit 15 in the gas sensor 1 through the remote contr...

Embodiment 3

[0041] See figure 1 , 2 And 5, the online calibration method of the gas sensor of the mine safety monitoring system of the present embodiment, comprises the steps:

[0042] ①. After the user sets a gas sensor 1 in the calibration state through the monitoring server 5 on the well, the sensor number information and calibration status information corresponding to the gas sensor 1 are sent to the monitoring sub-station 2 through the communication network; the monitoring sub-station 2 marks The gas sensor 1 is in the calibration state; the display digital tube 16 of the gas sensor 1 prompts that it is in the calibration state.

[0043] ②. On-site ventilation calibration of the gas sensor 1, that is: the user sends a sensor calibration command to the infrared receiving circuit 15 in the gas sensor 1 through the remote control of the gas sensor 1, and the center of the gas sensor 1 connected to the infrared receiving circuit 15 The control unit 11 enters the calibration state after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com