Safe lithium battery case

A technology for lithium batteries and battery casings, which is applied to battery components, circuits, electrical components, etc., can solve problems such as deformation of battery casings, failure to consider pressure relief effects, and low commercial value, so as to avoid battery The effect of reduced capacity, suitable for popularization and use, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

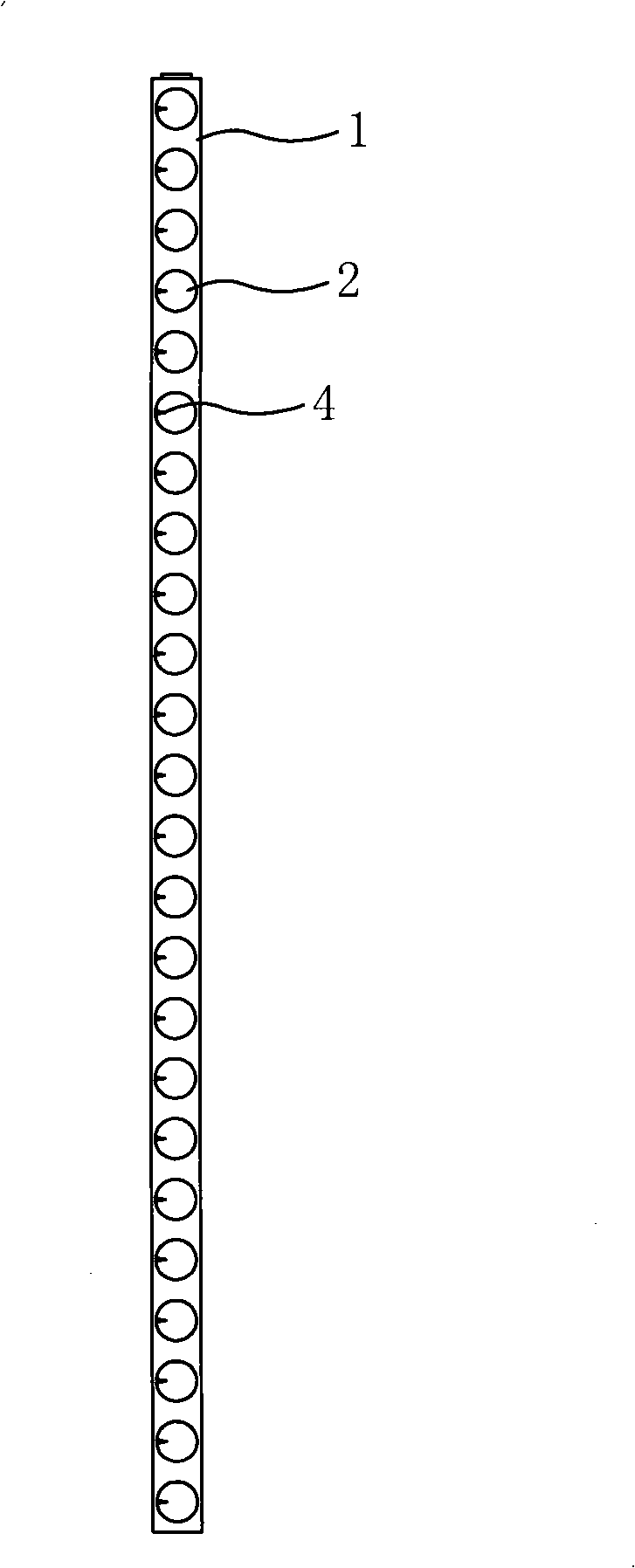

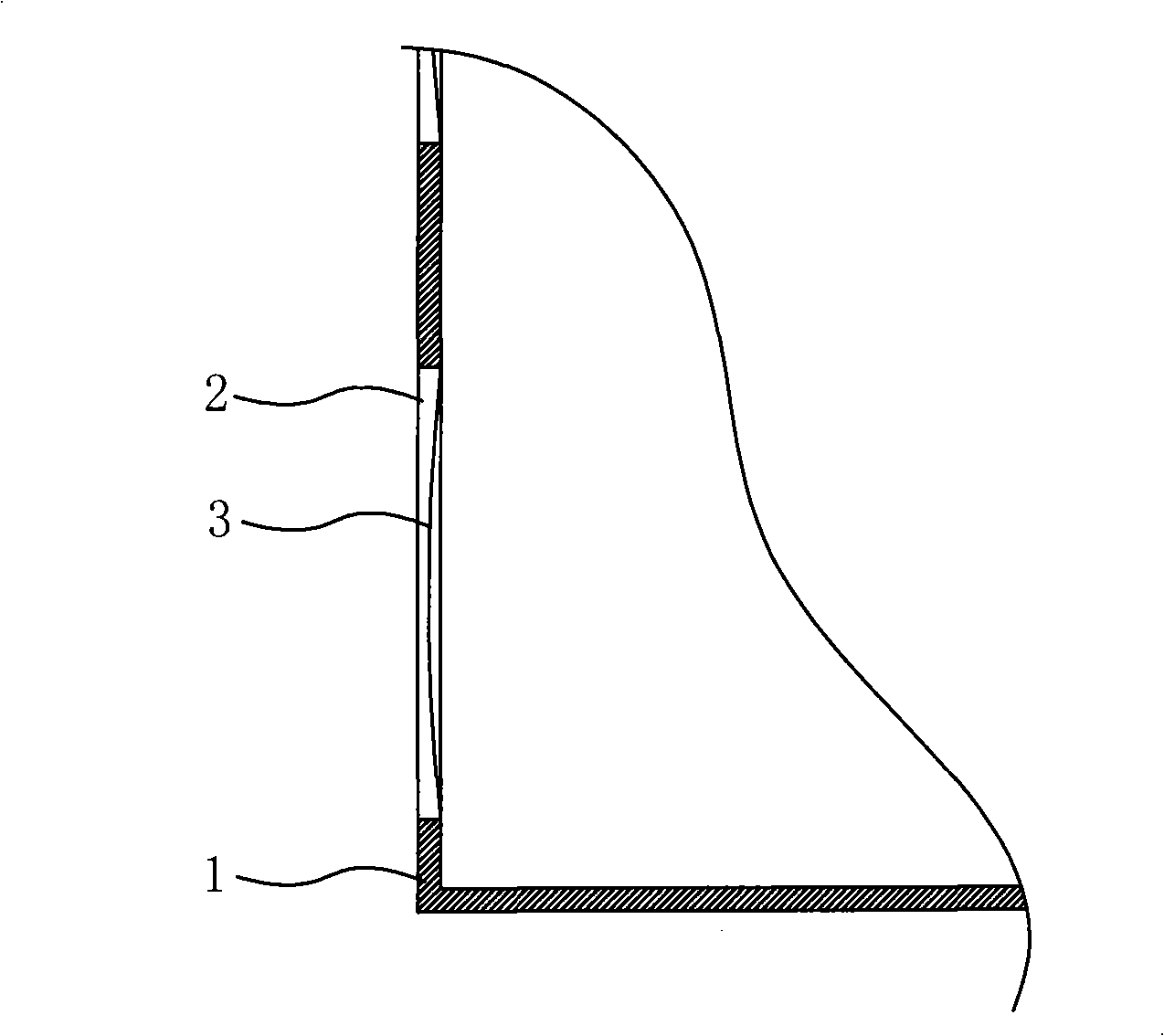

[0020] Embodiment one: see attached figure 1 to attach Figure 4 As shown, a safe lithium battery case includes a battery case body 1 and an electrode lead-out sealing structure, the case body is a narrow strip structure, the height of the case body is greater than 100mm, and the The height is greater than 10 times the width or thickness, and a plurality of explosion-proof holes 2 are arranged on the long and narrow side of the shell body, and the explosion-proof holes are covered with an explosion-proof film 3, and the explosion-proof needles 4 are arranged on the explosion-proof holes , the explosion-proof lancet can be punched and formed when the shell is punched.

[0021] When the battery is in use, when charging produces outgassing, the explosion-proof film bulges outward to provide a gas storage space. When the pressure inside the battery casing is too high, the explosion-proof film ruptures, releasing the pressure in time to prevent the battery from exploding.

Embodiment 2

[0022] Embodiment 2: A safe lithium battery case for assembling a 10AH power lithium battery, which is in the shape of a cuboid, with a body height of 400mm, a width of 28mm, and a thickness of 12mm. There are 25 explosion-proof holes arranged on the two narrow and long sides. Each explosion-proof hole is a circle punched with a needle structure.

[0023] Since 50 explosion-proof holes are provided in this embodiment, it is equivalent to one explosion-proof hole corresponding to every 0.2AH. The height of the original 10AH lithium battery case is about 80mm, and there is only one explosion-proof hole on the top. Therefore, the shell of this embodiment is not easy to explode and has high safety; meanwhile, there is a variable space for accommodating gas evolution, so the service life can be extended to 1.5 times of the original.

Embodiment 3

[0024] Embodiment 3: A safe lithium battery case is in the shape of a cuboid, the height of the case body is greater than 100mm, and at least 10 explosion-proof holes are provided on the narrow and long sides of both sides, and each of the explosion-proof holes is oblong or elliptical. shape, square or triangle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com