Preparation method and application of MOFs derived cobalt sulfide particle composite carbon material

A particle composite and carbon material technology, applied in the field of electrochemical energy storage, can solve the problems of cobalt sulfide pulverization, electrochemical performance decline, volume expansion, etc., and achieve the effects of good dispersion, low raw material cost, and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

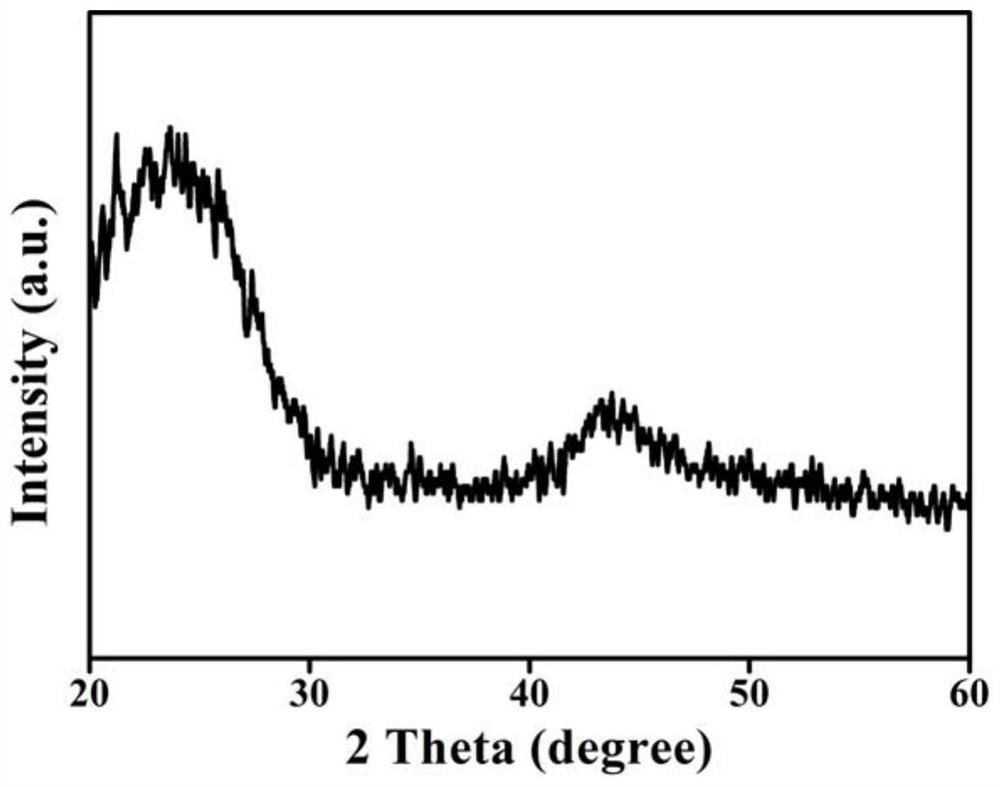

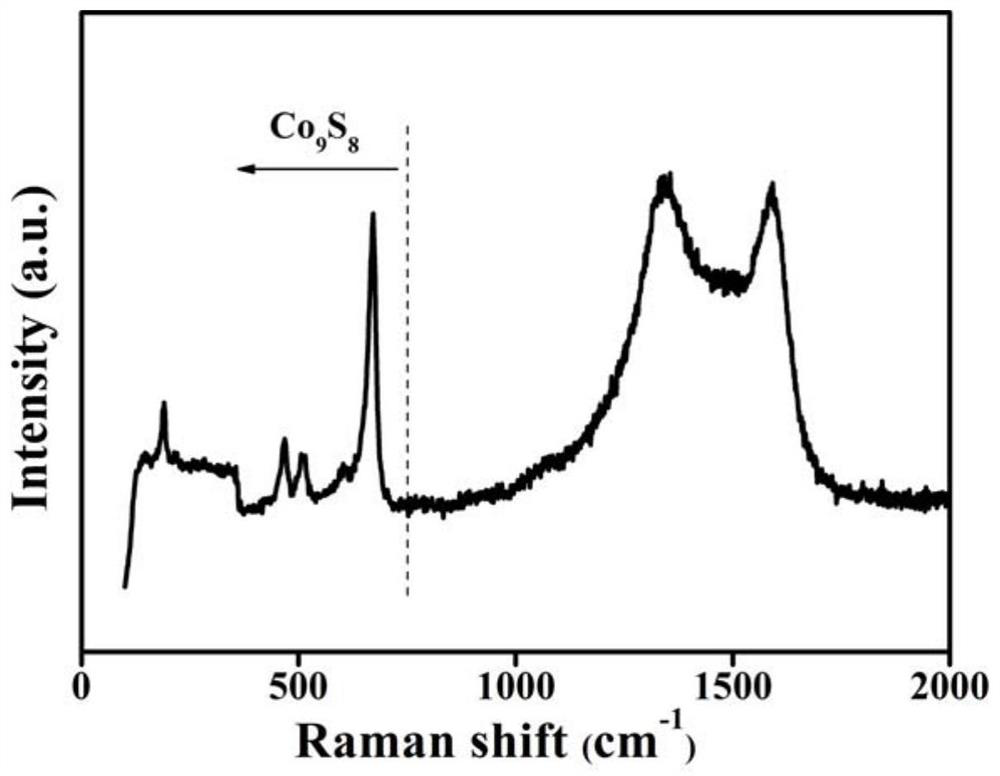

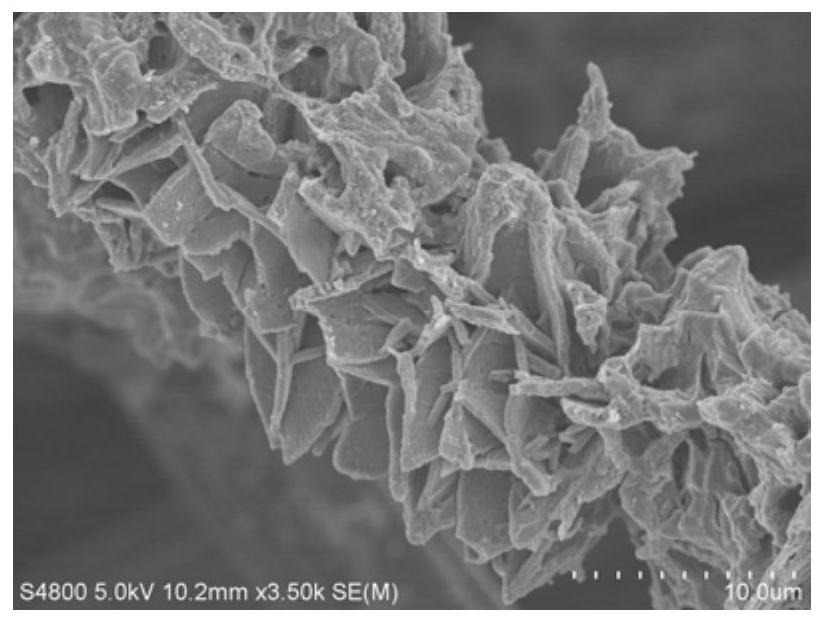

Method used

Image

Examples

Embodiment 1

[0034] 1) Weigh 0.4g cobalt nitrate hexahydrate and 1.5g 2-methylimidium At the same time, add it to 50mL of deionized water, and stir until it is completely dissolved to obtain solution A;

[0035] 2) Put the carbon cloth into the acetone solution for 24 hours, and wash it alternately with deionized water and absolute ethanol for 3 times, and dry it in a vacuum oven at 60°C for 5 hours. The pretreated 3*3cm hydrophilic carbon cloth Soak in solution A, and let it stand at 40°C for 12 hours; after the reaction, wash the carbon cloth with deionized water and absolute ethanol alternately for 3 times, and dry it in a vacuum drying oven at 60°C for 5 hours to obtain carbon cloth A;

[0036] 3) Put carbon cloth A into a porcelain boat, and calcine in an argon atmosphere to obtain carbon cloth B; the calcination temperature is 480°C, the holding time is 0.5h, and the heating rate is 2°C / min;

[0037] 4) Dissolve a certain amount of thioacetamide in ethylene glycol, control the sulf...

Embodiment 2

[0040] 1) Weigh 0.6g cobalt nitrate hexahydrate and 1.8g 2-methylimidium At the same time, add it to 50mL of deionized water, and stir until it is completely dissolved to obtain solution A;

[0041] 2) Put the carbon cloth into the acetone solution for 32 hours, and wash it alternately with deionized water and absolute ethanol for 5 times, and dry it in a vacuum oven at 65°C for 8 hours. The pretreated 3*3cm hydrophilic carbon cloth Soak in solution A and let it stand at 50°C for 16 hours; after the reaction, wash the carbon cloth alternately with deionized water and absolute ethanol repeatedly, and dry it in a vacuum oven at 65°C for 8 hours to obtain carbon cloth A;

[0042] 3) Put carbon cloth A into a porcelain boat, and calcine it in an argon atmosphere to obtain carbon cloth B; the calcination temperature is 500°C, the holding time is 1.5h, and the heating rate is 4°C / min;

[0043] 4) Dissolve a certain amount of thioacetamide in ethylene glycol, control the sulfur sou...

Embodiment 3

[0046] 1) Weigh 0.8g cobalt nitrate hexahydrate and 2g 2-methylimidium At the same time, add it to 50mL of deionized water, and stir until it is completely dissolved to obtain solution A;

[0047] 2) Put the carbon cloth in the acetone solution for 36 hours, and wash it alternately with deionized water and absolute ethanol for 6 times, and dry it in a vacuum oven at 75°C for 12 hours. The pretreated 3*3cm hydrophilic carbon cloth Soak in solution A and let it stand at 55°C for 18 hours; after the reaction, wash the carbon cloth alternately with deionized water and absolute ethanol repeatedly, and dry it in a vacuum oven at 75°C for 12 hours to obtain carbon cloth A;

[0048] 3) Put carbon cloth A into a porcelain boat, and calcine it in an argon atmosphere to obtain carbon cloth B; the calcination temperature is 600°C, the holding time is 2h, and the heating rate is 5°C / min;

[0049] 4) Dissolve a certain amount of thioacetamide in ethylene glycol, control the sulfur source co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com