Preparation method and applications of high specific capacity sulfur-containing positive electrode material

A cathode material, high specific capacity technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of pulverization and shedding of electroactive substances, dissolution loss, increase in internal resistance, etc., to increase the overall specific capacity, raw materials, etc. Easy to obtain, the effect of overcoming capacity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

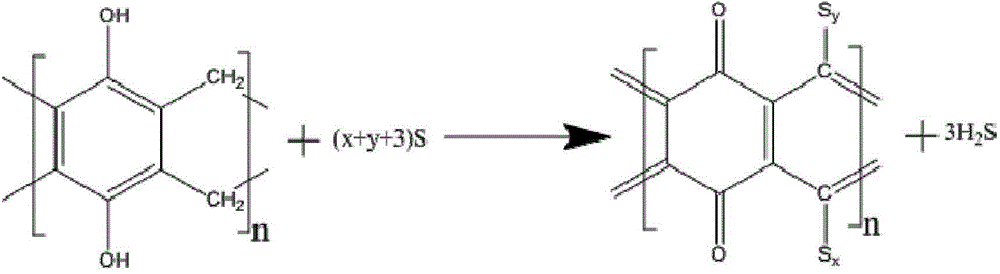

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a high specific capacity sulfur-containing cathode material, comprising the following steps:

[0024] (1) Synthesis of trapezoidal polymer nanoribbons

[0025] Dissolve 1.10 grams of hydroquinone in 100 mL of water, add 10 grams of concentrated hydrochloric acid, stir well, add 2.0 grams of 37wt% formaldehyde, stir well, transfer to a polytetrafluoroethylene reactor, react at 200 ° C for 12 hours, and cool naturally Then filter, wash with ethanol, and dry to obtain a brown-black spongy powder.

[0026] (2), vulcanization of polymer nanoribbons

[0027] Weigh 0.5 g of polymer nanobelts and 0.5 g of sublimed sulfur powder, mix them in a mortar, transfer them into a boron glass test tube, vacuum seal the tube, heat to 500°C and keep it warm for 0.5 hours, after natural cooling, open the glass tube tube to remove the sample. .

[0028] Electrochemical performance test

[0029] The sulfur-containing positive electrode material obtained in step (2)...

Embodiment 2

[0032] A method for preparing a high specific capacity sulfur-containing cathode material, comprising the following steps:

[0033] (1) Synthesis of trapezoidal polymer nanoribbons

[0034] Dissolve 1.10 grams of hydroquinone in 100 mL of water, add 10 grams of concentrated hydrochloric acid, stir well, add 2.0 grams of 37wt% formaldehyde, stir well, transfer to a polytetrafluoroethylene reactor, react at 180 ° C for 12 hours, and cool naturally Then filter, wash with ethanol, and dry to obtain a brown-black spongy powder.

[0035] (2), vulcanization of polymer nanoribbons

[0036] Weigh 0.5 g of polymer nanobelts and 4.5 g of sublimed sulfur powder, mix them in a mortar, transfer them into a boron glass test tube, vacuum seal the tube, heat to 350°C and keep it warm for 1 hour, after natural cooling, open the glass tube tube to remove the sample. .

[0037] Electrochemical performance test

[0038] The sulfur-containing positive electrode material obtained in step 2 was ...

Embodiment 3

[0041] A method for preparing a high specific capacity sulfur-containing cathode material, comprising the following steps:

[0042] (1) Synthesis of trapezoidal polymer nanoribbons

[0043] Dissolve 1.10 grams of hydroquinone in 100 mL of water, add 10 grams of concentrated hydrochloric acid, stir well, add 2.0 grams of 37wt% formaldehyde, stir well, transfer to a polytetrafluoroethylene reactor, react at 170 ° C for 12 hours, and cool naturally Then filter, wash with ethanol, and dry to obtain a brown-black spongy powder.

[0044] (2), vulcanization of polymer nanoribbons

[0045] Weigh 0.5 g of polymer nanobelts and 1.5 g of sublimed sulfur powder, mix them in a mortar, transfer them into a boron glass test tube, vacuum seal the tube, heat to 200°C and keep it warm for 12 hours, after natural cooling, open the glass tube tube to remove the sample. .

[0046] Electrochemical performance test

[0047] The sulfur-containing positive electrode material obtained in step 2 wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com