Pattern copy mask, focal distance fluctuation measuring method and apparatus, manufacture method for semiconductor device

A measuring method and a technology for replicating bodies, which are applied in the manufacture of semiconductor/solid-state devices, exposure devices for photoengraving processes, and photoengraving processes for patterned surfaces, and can solve problems such as small dimensional uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Essentials of the invention

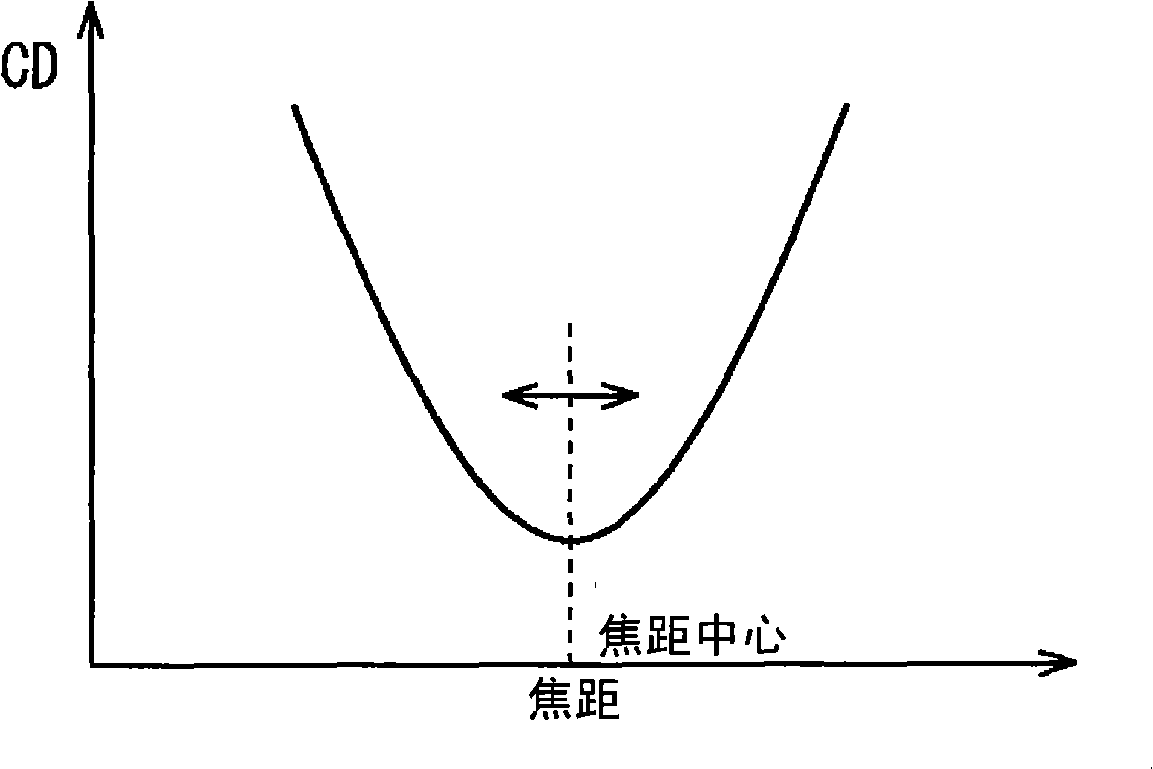

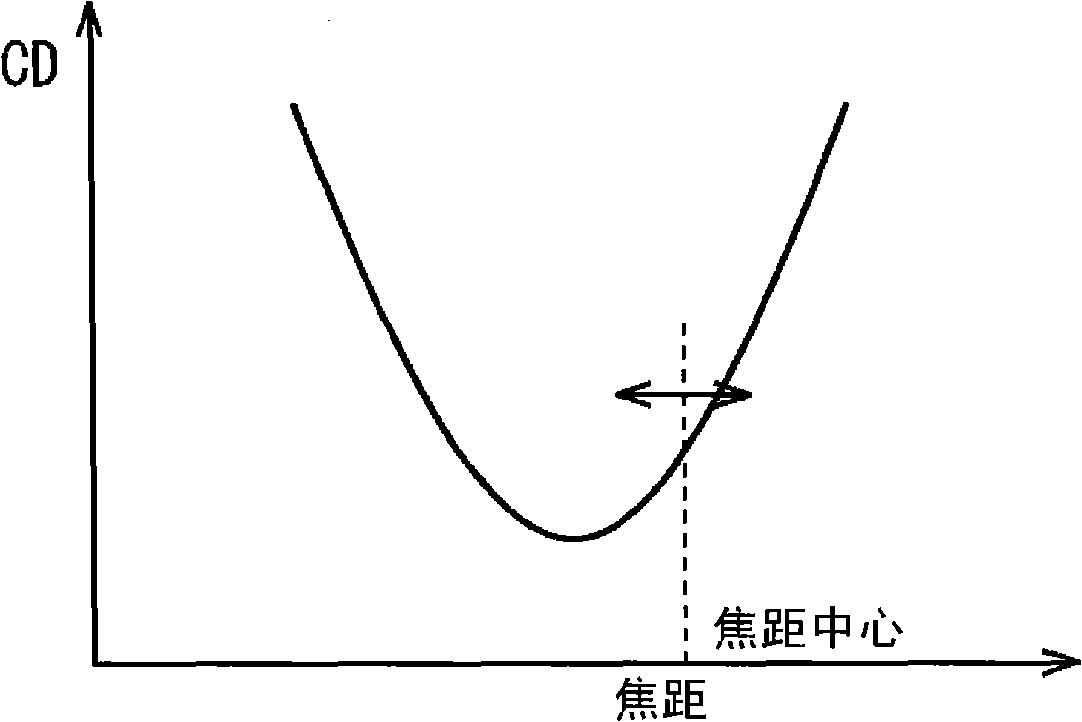

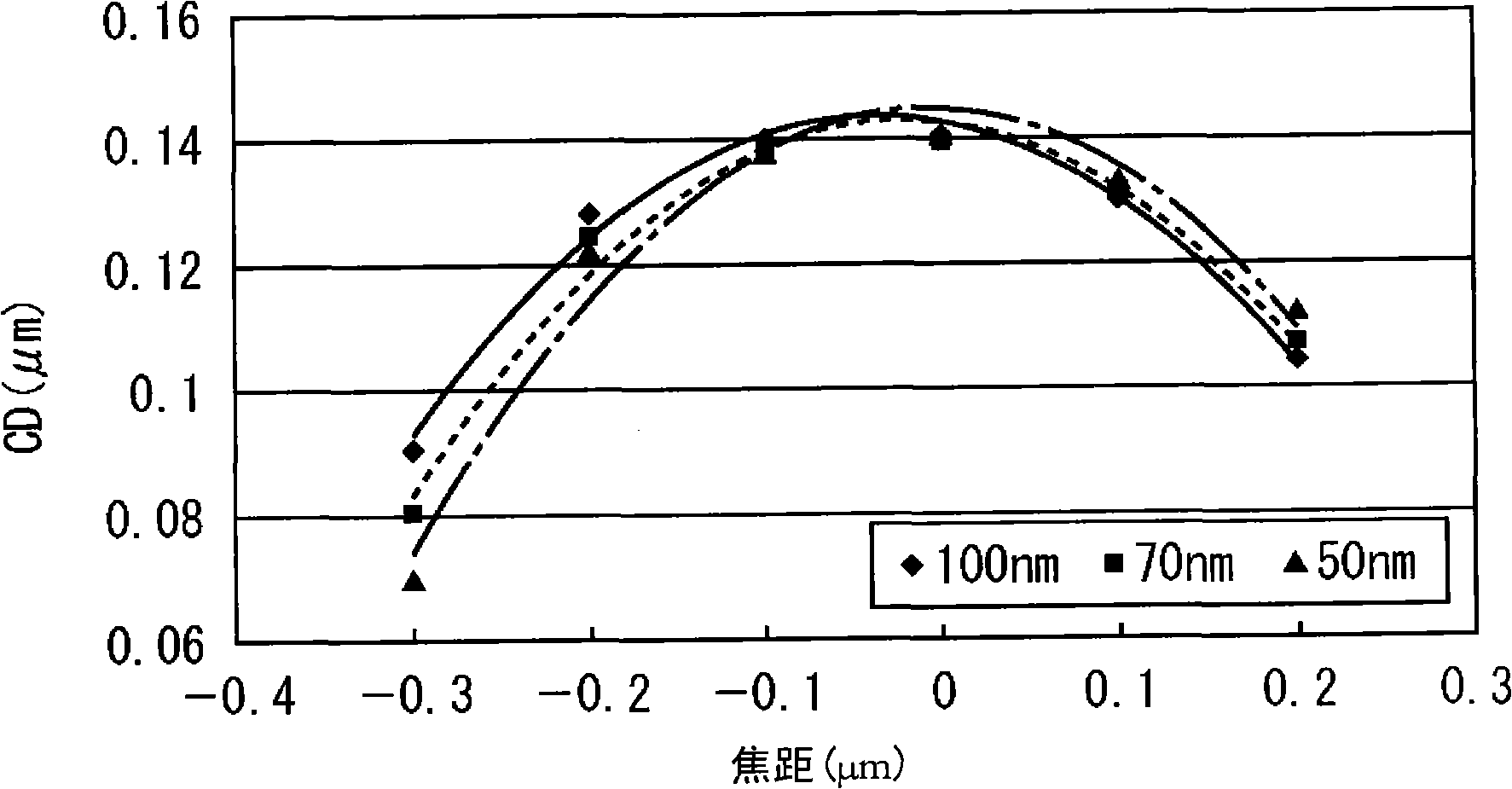

[0046] In general, the relationship between the focus offset (offset) value and the dimensional measurement value of the reproduced pattern can be drawn as a so-called CD-focus curve that can be approximated by an even-order function. exist Figure 1A An example of a CD-focal length curve is shown in . In this case, the extreme value of the focus offset value becomes the optimum focus value, that is, becomes the focus center. Here, since the distance between a pair of replicated patterns is used as the dimension measurement value of the replicated pattern, the focus shift value becomes a minimum value. In this way, the CD-focus curve is approximated by a quadratic function, so if a focus error occurs, it is difficult to determine whether the direction of deviation from the extremum is positive or negative. In addition, since the variation of the dimensional measurement value with respect to the focal length variation is extremely small in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com