System and method for measuring thickness distribution of semiconductor chips, grinding system and grinding method, and thickness allowance distirbution measuring method

A technology of thickness distribution and measurement system, which is applied in the direction of semiconductor/solid-state device testing/measurement, grinding device, grinding machine tool, etc., to achieve the effect of accurate data feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

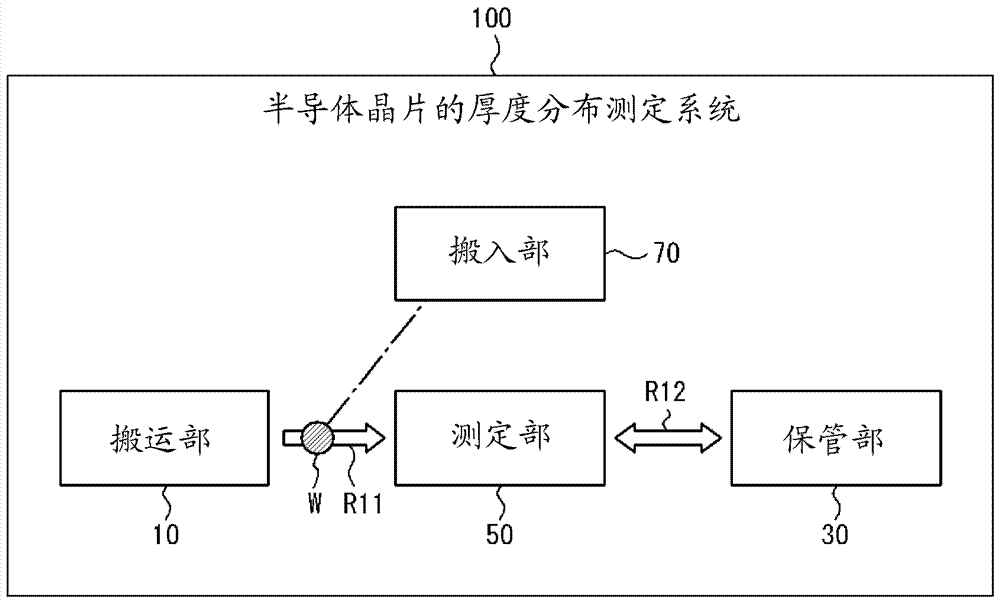

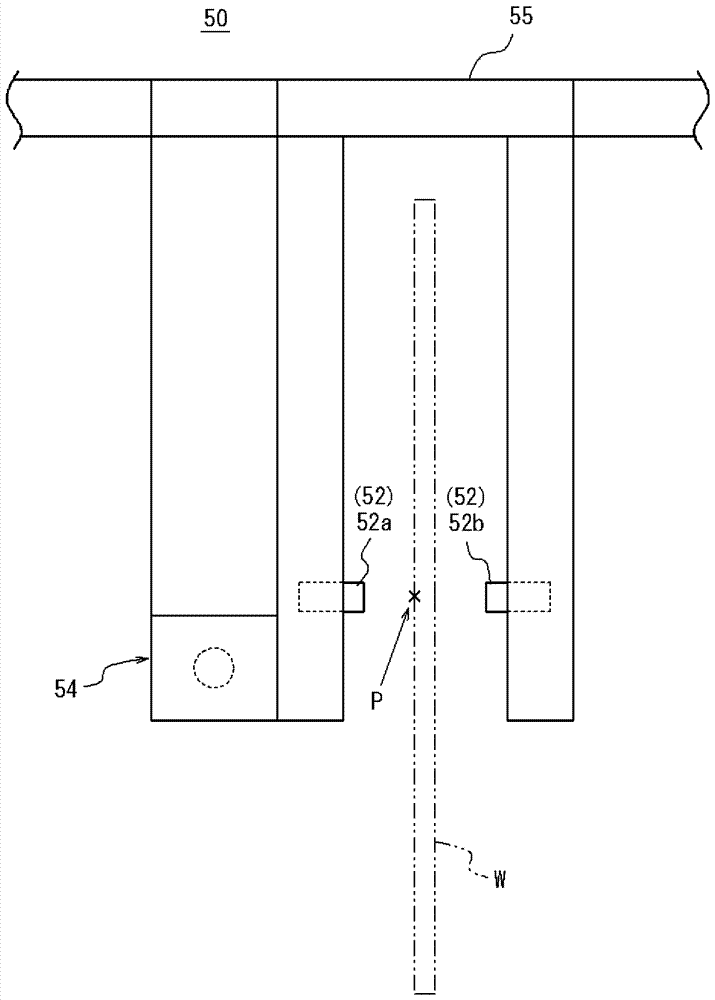

[0039] (First Embodiment: Semiconductor Wafer Thickness Distribution Measurement System)

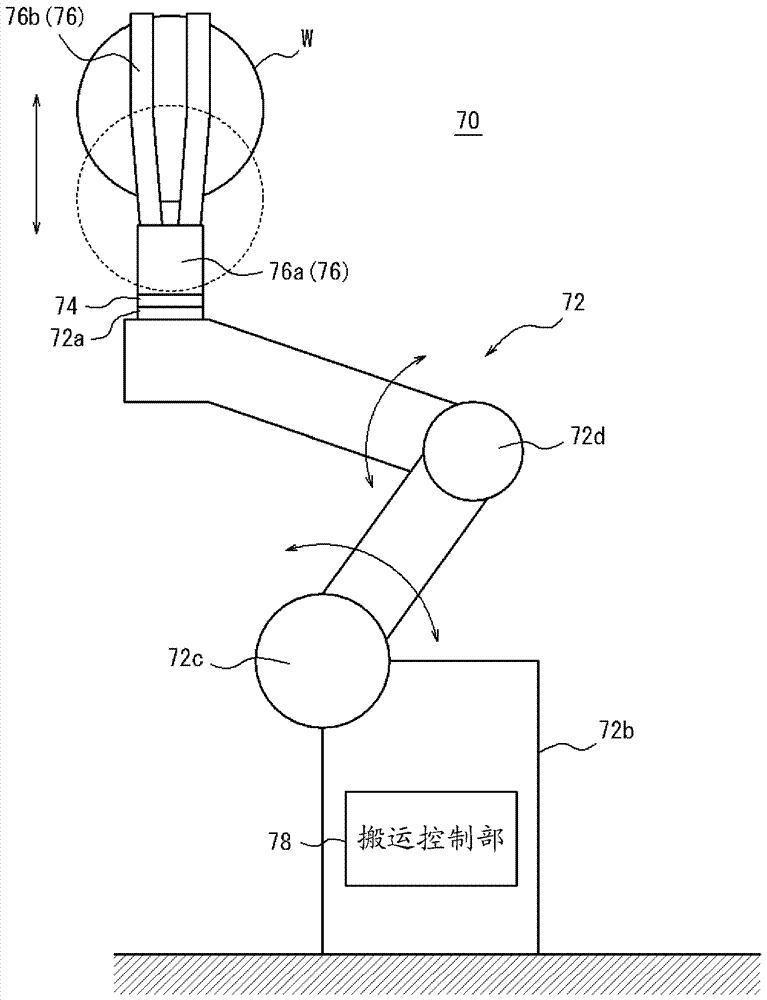

[0040] use figure 1 , FIGS. 3 to 5 illustrate a semiconductor wafer thickness distribution measurement system 100 according to an embodiment of the present invention. The semiconductor wafer polishing system 200 includes a loading unit 10, a storage unit 30, a measurement unit 50, and a transfer unit 70. The storage unit 30 stores the semiconductor wafer W in the storage unit 30, and the measurement unit 50 measures the thickness of the semiconductor wafer W. The transport unit 70 transports the semiconductor wafer W on the first transport route R11 between the loading unit 10 and the measurement unit 50 and the second transport route R12 between the storage unit 30 and the measurement unit 50 . Here, the conveyance unit 70 has a robot arm 72, a base 74, a robot arm 76, and a conveyance control unit 78. The robot arm 72 can move in the first conveyance path R11 and the second conveyance...

no. 2 Embodiment approach

[0063] (Second Embodiment: Semiconductor Wafer Polishing System)

[0064] use Figure 2~5A semiconductor wafer polishing system 200 according to one embodiment of the present invention will be described. The semiconductor wafer polishing system 200 includes a loading unit 10, a polishing unit 20, a storage unit 30, a measurement unit 50, and a transport unit 70. The loading unit 10 loads the semiconductor wafer W, the grinding unit 20 grinds the semiconductor wafer W, and the storage unit 30 stores For the semiconductor wafer W, the measuring section 50 measures the thickness distribution of the semiconductor wafer W, and the conveying section 70 passes through the first conveying path R21 between the carrying-in section 10 and the polishing section 20 of the measuring section 50, and the polishing section 20 and the measuring section respectively. The second conveyance path R22 between 50 conveys the semiconductor wafer W. Here, the transport unit 70 has a robot arm 72, a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com