Continuous circulating type oil-gas adsorption recovery method

It is an adsorption recovery and circulation technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems that oil and gas recovery cannot achieve continuous circulation, so as to prevent secondary pollution, facilitate remote monitoring, and have fewer interfaces. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

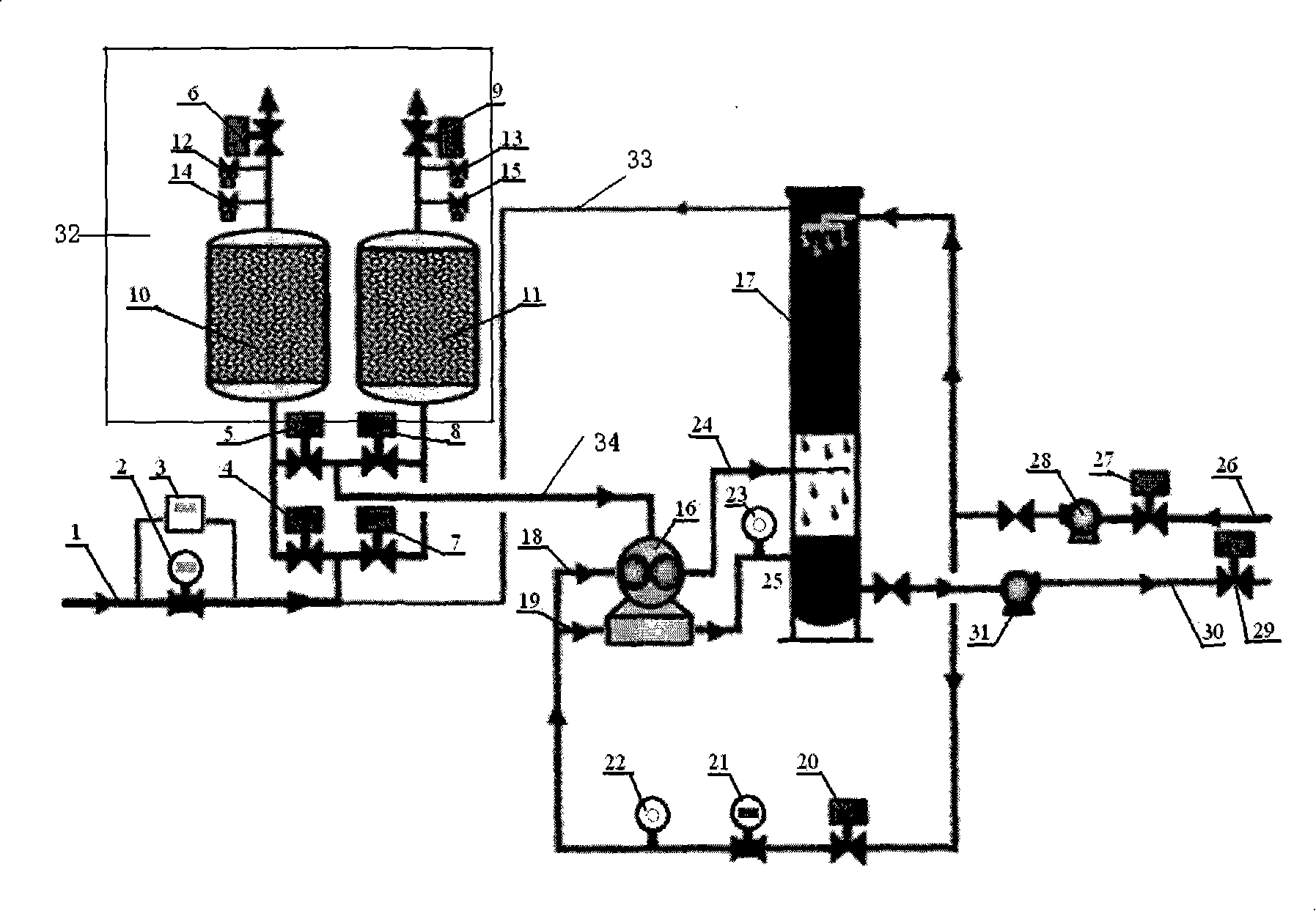

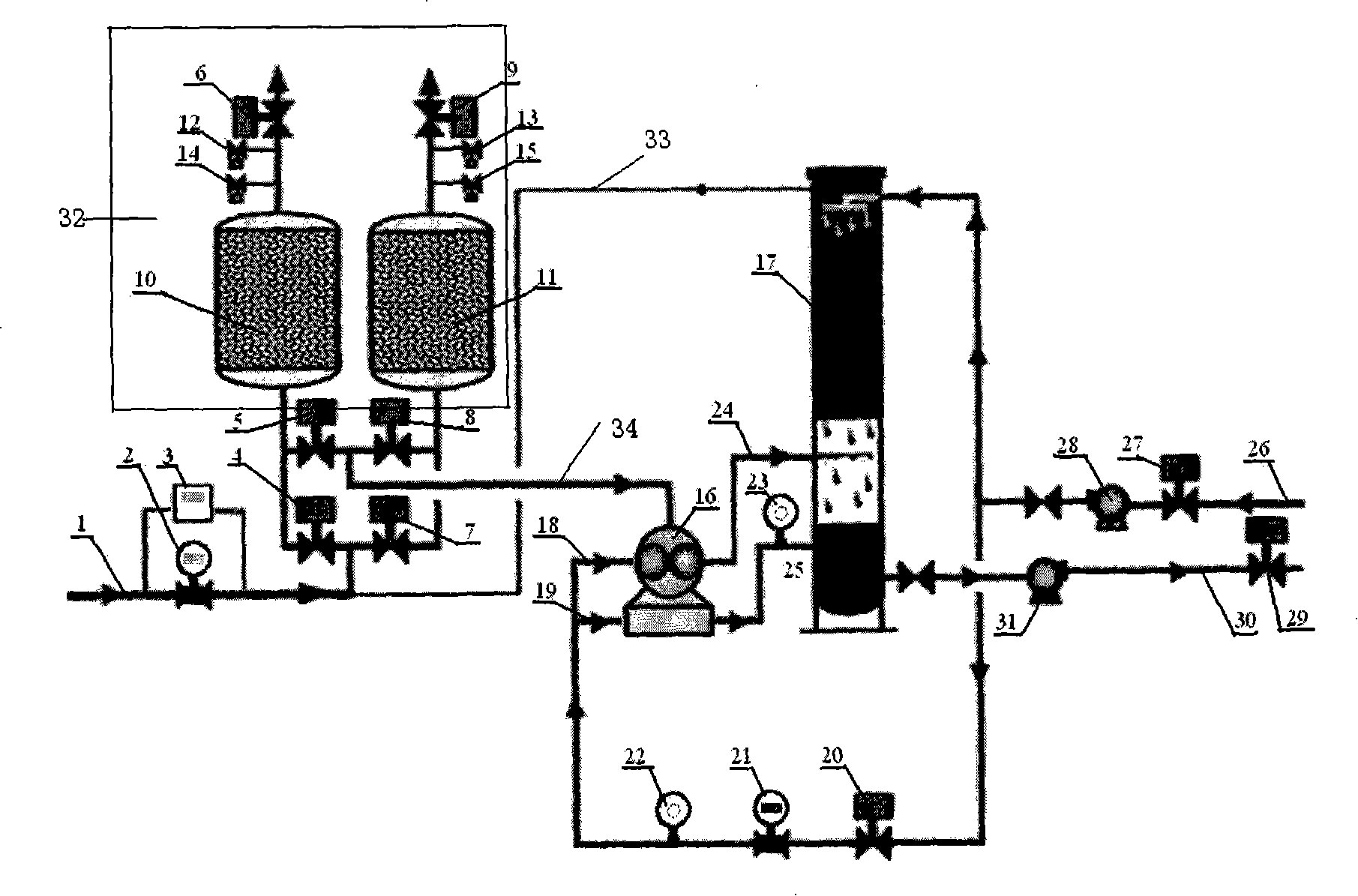

[0040] The oil and gas produced in the oil depot during the oil delivery process passes through the gas collecting pipe and the gas-liquid separation tank, and then enters the adsorption tower 32 through the oil and gas inlet pipe 1. The adsorption tower 32 is composed of the adsorption tank A10 and the adsorption tank B11. At this time, the electric valve I4 is opened. The electric valve II 5 is closed, the oil gas enters the activated carbon bed in the adsorption tank A 10 for adsorption and recovery, and the purified gas is discharged into the atmosphere from the electric valve III6. At this time, both the electric valve IV7 and the electric valve V8 are closed, and the adsorption tank B11 has not been activated yet.

[0041] When the adsorption tank A 10 is saturated, the electric valve IV7 is opened, the electric valve I 4 is closed, the oil gas enters the activated carbon bed in the adsorption tank B 11 for adsorption and recovery, and the purified gas is discharged into ...

Embodiment 2

[0049] It is basically the same as in Example 1, except that the adsorption tower is composed of three adsorption tanks, and the three adsorption tanks sequentially perform adsorption recovery of oil gas and desorption regeneration, so that the oil gas can be continuously circulated for adsorption and recovery.

Embodiment 3

[0051] It is basically the same as in Example 1, except that the adsorption tower is composed of five adsorption tanks, and the five adsorption tanks sequentially perform adsorption recovery of oil gas and desorption regeneration, so that the oil gas can be continuously circulated for adsorption and recovery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com